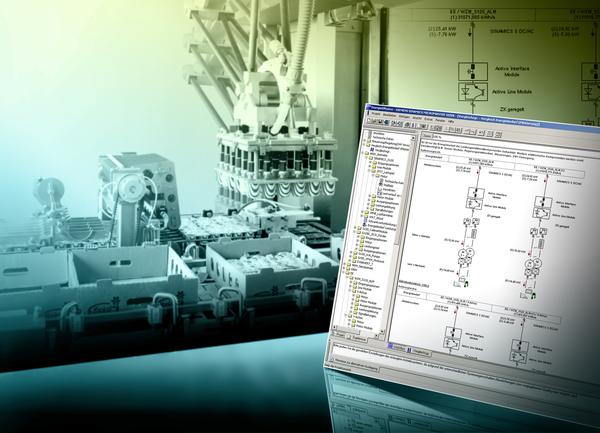

The Sizer software from Siemens Drive Technologies Division is an engineering tool for planning drive applications with Sinamics. With the new version Sizer 3.4, two drive solutions can now be compared with regard to their energy efficiency, enabling the savings potential to be determined. A conversion function makes it easy to modify drive configurations that have already been engineered and then to determine the effects on energy consumption so that the best variant can be selected.

Energy management is becoming more and more important in industry due to mounting energy costs, stricter environmental protection requirements and increased efforts to comply with certification in accordance with the international standard for energy efficiency EN 16001. Energy efficiency in production makes an especially important contribution to reducing costs in a plant and therefore improves competitiveness. The typical annual power consumption of ordinary production machines and machine tools is around 50,000 kWh. More than 50 % of the base load of a machine is consumed by equipment units such as coolant and lubricant pumps, infeed and conveyor units and compressed air or sealing air. It is therefore worthwhile conducting a detailed energy analysis of the drives involved and an energy comparison to discover whether significant savings in consumption could be achieved with a different drive constellation. The new Version 3.4 of the Sizer engineering software from Siemens offers, in addition to a load-dependent energy consumption calculation, a drive conversion program for automatically generating energy-saving drive variants.

Selection of the best variant

The energy analysis takes into account components such as the motor, power module, converter, line reactor, input reactor and output reactor as well as active interface modules. For the energy needs of the mechanical system the power required at the device is taken into account. Friction and degrees of efficiency of the mechanics are included here. For the motors load-dependent losses, such as copper and iron losses and losses due to friction and harmonics, are taken into account. For the power components current-dependent losses, such as conduction and switching losses, are considered. A power-dependent loss due to the output reactive power is also important and load-independent constant losses are included in the calculation. The total balance at an arbitrary operating point is the sum of the individual power losses at the respective operating point.

The Sizer function for drive conversion can be used to generate alternative drive systems with a more favorable energy balance from a previously engineered drive system. On this basis a decision to select the most efficient system can be made. Besides Sinamics also drive applications with Micromaster, Dynavert T and motor starter devices as well as Sinumerik, Simotion can be planned with Sizer.

Share: