Achema is traditionally the world’s leading forum for chemical engi-neering and the process industry. Which trends will determine what takes place beneath the trade fair tower in Frankfurt this year? Which exhibition groups have grown the most? And how do the new PRAXISforums work? We can tell you everything you need to know about Achema.

All eyes in the global process industry will be turned towards Frankfurt: for a whole week starting on 15 June 2015, nearly 3800 exhibitors will once again present products, technologies and know-how for chemical production and the food and pharmaceutical industries on around 132,000 m2 of floor space.

Spotlight on three focal themes

Three focal themes selected for the week by Achema will be running in concert across all exhibition groups: Process Analytical Technology, Industrial Water Management and Biobased World, as a platform for the biobased industry and biotechnology, will be spotlighted at various locations around the exhibition and congress. The organisers will provide visitors who are keen to learn more about these themes with background information and guidance in the form of special publications, markings and Achema app features.

In addition to the focal themes, three top trends will dominate this year’s mega event in Frankfurt: the increasing modularisation and automation of plants and processes, the perennial issue of energy and resource efficiency and integrated process design – all of which will inevitably mean further networking across multiple industries and disciplines.

Components as communicators

Most of the topics currently being debated in other industries under the heading Industry 4.0 are equally relevant for process engineering. It isn’t so much the product components which communicate with one another here as the individual components of the plant: a pump in a modular plant reports its availability and performance range not only to the central control system but also to the valve while a temperature measurement triggers heating and cooling – or the next process step.

New opportunities for process control far beyond the actual technology will emerge in the chemical industry, for example in relation to shift design or personnel management. Workflows will accordingly become more and more flexible – from the lab to the packaging technology, which will firstly become increasingly „single source“ and secondly deliver solutions which can be adapted to new products, so to speak, at the push of a button – from the formulation to the primary and secondary packaging.

A holistic approach is called for

Efforts to improve energy and resource efficiency – including industrial water management – are leading to ever more extensive process integration. Heat and raw materials recovery and the widespread use of closed systems presuppose a holistic approach to, and design of energy, material and heat flows from the outset. It is no longer simply individual processes which are linked together; whole plants and sites are planned in an integrated manner.

The aim is that process control systems should also be able to respond to variations in the energy and raw materials supplies. The increasing use of renewable energy sources, for instance, results in fluctuating electricity generation, which could then be compensated more efficiently. Especially with biomass, the availability and composition of the raw materials differ significantly depending on the region and as a function of time; materials are more common in some countries than in others – such as shale gas in the U.S. or coal in China – forcing plant manufacturers and producers to offer a broad portfolio of technologies.

China in competition with Italy

Both the chemical and pharmaceuticals sectors and food and beverages are strongly internationalised industries. The same applies to plant, apparatus and component manufacturing, from which these three core segments of process engineering source their products. This situation is also reflected in the high proportion of foreign exhibitors at Achema, which for the first time will exceed 50 %.

The biggest share is accounted for by China, which will be competing with Italy as the country with the second largest number of booths (after Germany). This threesome will be followed by the U.S., the U.K., India, Switzerland and France. All in all, exhibitors from 55 different countries will take part in the world forum for the process industry.

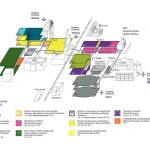

Out of all the exhibitor groups, „Pharmaceutical, Packaging and Storage Techniques“ has expanded the most dynamically. It has literally „grown out“ of Hall 3 and will occupy two additional spaces this year in the Forum and the Agora Pavilion. „Achema is the world’s premier trade fair for the industry. All leading international manufacturers will be represented there“, explained Richard Clemens, Managing Director of the Food Processing Machinery and Packaging Machinery Association within the German Engineering Association (VDMA), at a press conference at the end of April.

The most sizeable exhibitor group by a long way is still „Pumps, Compressors, Valves and Fittings“, underlining Achema’s traditional role as the world’s number one show for this sector of industry. „Measuring and Testing Technology“ has likewise grown in importance – unsurprisingly in view of the current trend towards higher degrees of automation.

Showcase for tomorrow

With some 800 lectures, the Achema Congress 2015 will once again be a showcase for tomorrow’s innovations. Materials, biorefineries and classic process technologies will be among the key topics covered. Thanks to the new Praxis-forum format, certain themes will also be shifted into the immediate vicinity of the exhibition groups concerned – a unique opportunity for exhibitors and visitors to communicate with one another directly and get a closer insight into exhibits of particular interest. Numerous guest events under the umbrella of national and international organisations will additionally emphasise Achema’s immense relevance as a meeting place for disciplines like safety engineering, powder and nano technology or high-throughput research.

Share: