Circuit breakers are used in almost all industries to increase availability. The Phoenix Contact device circuit breaker board is available in three different versions with 4, 8 or 12 channels. Remote signalling is divided into two groups and the complete board can be monitored by means of one or two PLC inputs. Device circuit breakers can be mounted on the board to protect loads and wiring against overload and short-circuit currents.

Author Peter Ketler Product Manager Power and Signal Quality Trabtech, Phoenix Contact

A lot can be learned from applications that have proved successful in the market over many years – for example, with regard to ease of installation and space savings. The groups of loads to be protected should be optimally coordinated in order to guarantee adequate availability. Targeted shutdown must be ensured in the event of a fault without any other system parts being affected.

If a manufacturer wants to establish a new market standard, they must be able to explain to their customers what the advantages are: system manufacturers always keep their ears open for benefits such as a smaller footprint, reduced installation time and integrated potential distribution. In practice, protection for systems and loads is invariably designed according to the same principle.

However, the number of loads or groups of loads to be protected varies from system to system. The standard configuration usually has 230 to 400 V(AC) on the primary side.

The individual sensors and actuators are supplied via 24 V(DC) switched-mode power supply units, which in most cases are rated with 10 to 40 A. Large systems often also use several power supply units to provide the required power. After all, the aim is to ensure that the system runs with as few interruptions as possible.

Future system expansions are taken into consideration in the planning phase by incorporating reserves of anything from 20 to 50 %. These reserves also serve as protection in the event of a fault, as this is the only way that the necessary high tripping currents can flow. The thermomagnetic circuit breakers used here, for instance, trip immediately if a fault occurs. The other system parts continue to operate normally.

Reliable protection for load groups

The protection concept consists of multiple channels which protect the loads in the system. In order to achieve selective protection, the individual devices are for the most part protected separately. However, some device groups are also protected together – generally due to economic considerations. This definitely makes sense from the system’s point of view if operation of the various loads in the group is interdependent. The nominal current of the devices should be roughly identical to ensure that a suitable circuit breaker is selected. If one device in the group fails, the entire group is shut down. Other groups continue working without interruption.

In the event of overload, the thermomagnetic device circuit breakers trip mechanically after a time delay with the aid of a bimetal. This is referred to as thermal shutdown. If a short circuit occurs as a result of a fault, a solenoid shuts down the protected device or the complete system section immediately to prevent other sections from failing. Three different characteristics are available depending on the load. Each device circuit breaker offers a floating PDT contact and electrically isolates the protective path – regardless of whether the shutdown was manual or because a fault occurred.

Three characteristics offer efficient protection for different loads:

- The fast-blow F1 characteristic protects devices with a low inrush current

- The SFB characteristic is an optimised C characteristic that was designed to protect devices with a higher inrush current. It reduces the amount of residual current flowing and enables longer cable paths – while still ensuring reliable tripping

- The medium-blow M1 characteristic offers even slower tripping and is used for devices with sustained high inrush currents

Circuit breaker system

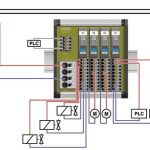

These device circuit breaker boards from Phoenix Contact are the ideal solution for series production of machinery and process technology. They are compatible with the thermomagnetic device circuit breakers in the CB product range and are conveniently fed with up to 60 A from a central supply. There is no need for bridging thanks to the conductive paths. Three versions with 4, 8, and 12 channels are presently available. They are designed as PCB solutions for accommodating thermomagnetic device circuit breakers. Between four and twelve channels are protected against the effects of overload and short-circuit currents.

Behind the protected outputs of the circuit breakers are plug-in PCB terminals with push-in connection technology, which enable installation time to be drastically reduced. Each protective path has five terminals for the protected positive pole and five for the negative pole to ensure quick and easy potential distribution. Each path therefore offers the option of supplying a group of five loads positively and negatively without having to use terminal bases. All circuit breakers are monitored with the aid of integrated group signalling. If a circuit breaker is tripped due to a fault, the signal circuit is interrupted and an error message can be processed. The groups can be divided into two signal groups of equal size to make it easier to locate the fault.

A lot of space can be saved by using device circuit breaker boards instead of conventional technology thanks to their slim design. In addition, far fewer accessories and significantly less installation time are required to protect a machine’s loads. The individual current paths can be adapted quickly – the circuit breaker is simply removed and replaced with the appropriate current and characteristic.

Series switchgear can be simplified and stand-ardised even further. Phoenix Contact’s device circuit breaker boards are a system solution that can be tailored to a wide range of applications. The number of channels and the way in which remote signalling is implemented can likewise be adapted to highly specific requirements. The resulting boards can be ordered at any time as standard products.

Hall 9, Booth F40

cpp-net.com/0114429

Share: