In today’s pharmaceutical and chemical industry, high investments for cutting-edge process technology, including central and remote control units, are common practice. Downtimes of such capital-intensive production lines would cause immense losses. For all this upgrading and modernisation on the automation and process control level, protection of the field level with its 24 V(DC) supplies is often neglected. Frequently, the technology used for sensor and actuator protection has fallen behind and – unlike the rest of the automation system – is no longer state of the art.

Jürgen Ziarnetzki

Admittedly, protection of the 24 V(DC) field level is not that easy. Selective disconnection of the faulty load circuit requires an optimal match between the power supply unit, the cabling, the protection concept applied and the load circuits. As power supplies, loads, cable lengths and cable cross-sections with different characteristics tend to be installed, only a systematic approach will ensure sustained availability.

The DIN VDE 0100-725 and DIN EN 60204-1 standards both call for protective elements against short-circuits, even in auxiliary control circuits such as the 24 V(DC) field level. These elements need to protect electrical equipment and cables against overheating, fire and destruction.

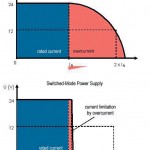

In addition, control circuits have to be protected against overcurrent as stipulated in Section 9.1.3 of DIN EN 60204-1. The protection approach adopted must therefore be capable of responding to both overcurrent and short-circuit. In practice, however, there is hardly ever a clear distinction between the two overcurrent types. Another important fact to consider is the somewhat vague response of standard circuit breakers, as their performance is strongly affected by outside influences. Thus, for instance, the line attenuation due to long cable paths or the current limiting function integrated in today’s 24 V solid-state switched-mode power supplies (SMPS) often prevents reliable fault tripping of the protective elements in the event of a short-circuit or persistent overload.

The advantages of a distributed 24 V power supply scheme using modern switched-mode power supplies are obvious: low cost of purchasing, maintenance and installation, little space requirement, enhanced safety due to shorter cabling and last but not least ease of troubleshooting. However, these advantages can only be brought to bear within an integrated overall concept.

Another fact should be considered in spite of all the benefits offered by today’s switched-mode power supplies: due to their integrated, auto-protective, current limiting facility they respond to an overload by reducing their output voltage, even down to zero volts in the worst case. And a short-circuit will most certainly provoke a hiccup condition, in other words the SMPS device shuts down completely leaving all loads connected to it without supply.

Limitations of conventional circuit breakers

Today’s industrial automation systems increasingly employ solid-state components and equipment, even on the machine-oriented sensor/actuator and PLC level. Their high content of capacitive components, required for interference suppression, generates a short high inrush current during switch-on. Standard thermal-magnetic circuit breakers with fast A or Z tripping characteristics are not capable of withstanding these inrush peaks and trip instantaneously. As a result, these fast-acting circuit breakers do not even allow sensors and actuators to be switched on.

Installing a circuit breaker with a medium-delay C tripping characteristic is no remedy either. Although tolerant of high inrush currents, these devices only trip with a considerable delay – if at all – due the high magnetic tripping current they require. The switched-mode power supply with its integrated, protective, current limiting function responds much faster and shuts down the output voltage. All loads connected to the 24 V(DC) supply are then dead-voltage. This can cause a complete failure of the automation system and thus of the process, since all loads – even those unaffected by the overload or short-circuit fault – switch off in an uncontrolled manner.

The short-circuit current actually flowing can create an additional hazard because it depends on the line resistance of the load connection (which incidentally is mostly unknown), in other words on the length and cross section of the connected cables. Circuit breakers with a C characteristic, therefore, often do not reach their magnetic tripping threshold of up to 15 times the rated current. As a result, failures remain undetected and can lead to an indefinable risks. Troubleshooting is impeded by the fact that no circuit breaker has tripped, because the switched-mode power supply was faster. Especially in situations where sporadic short-circuits occur due to faulty cable insulation, the root cause of this kind of failure is very hard to pinpoint.

Selective protection

The basic requirement is to quickly and selectively disconnect the faulty circuit, keep the system up and running, and at the same systematically distinguish between overload, short-circuit and inrush peaks. E-T-A’s electronic protection concept is an example of an integrated overall solution.

The ESS20 electronic circuit breaker provides physical isolation, thus reliably disconnecting the faulty path before the switched-mode power supply can detect the overload or short-circuit and go into its auto-protection mode. The availability and safety of the system are ensured. The integrated status indication of the ESS20 allows quick and easy troubleshooting.

The ESS20 electronic circuit breaker prevents the load current from exceeding 1.8 times the rated current. Its integrated current limiting function protects loads, cables and the power supply.

E-T-A’s electronic circuit breakers provide a number of additional functions. The current rating range is from 0.5 to 10 A (ESS20) or from 0.5 to 12 A (ESX10). There are also versions with two fixed current ratings that can be selected with a switch. The ESS20, which can also be used as an electronic supplementary protector due to its UL 1077 approval, offers genuine disconnection of the faulty path from the power supply by means of physical isolation, thus providing the high degree of safety and protection paramount in plants in the pharmaceutical or chemical industry.

Where physical isolation is not a mandatory requirement, the ESX10 electronic circuit protector is suitable. This device likewise offers precise fault signalling after electronic disconnection – visually by means of an LED and electrically through an auxiliary contact.

High inrush peaks of capacitive loads do not present a problem to either of these devices. While they immediately trip in the event of short-circuit and issue a fault indication, they tolerate short inrush currents of capacitive loads up to 20,000 µF. Instantaneous tripping within 100 ms at short-circuits as well as overload disconnection after 5 s with load currents that are typically higher than 1.1 times rated current ensure reliable protection of plants and maximum availability of electrical systems.

The integrated current limiting function of the devices protects reliably and prevents voltage dips of the 24 V(DC) switched-mode power supply. Even long cable paths become controllable.

Protection and power distribution

The protection concept ensures a reliably protected 24 V(DC) power supply. In addition, various power distribution systems in the SVS series offer economic and systematic ways of load and potential distribution as well as possibilities for single and group signalling. Pre-assembled distribution and cabling, as well as auxiliary contact outputs on a single distribution panel, not only save space and wiring time but form the basis of systematic failure management and allow error diagnostics to be integrated in the PLC and visualisation platform.

Ease of mounting and troubleshooting, time saving aspects and simpler plant construction thanks to the availability of Eplan macros represent a giant step towards system integration and a clear competitive edge for electronic circuit breakers and their system technology.

Hall 11, Booth B62

cpp 424

More Products from E-T-A

Share: