Many industrial sectors are focusing increasingly on additive manufacturing of components made of metal or polymers. Selective laser sintering (SLS) constitutes an important process for 3D printing of polymers. Fine polymer powders are sintered in a powder bed by means of laser to form three-dimensional objects. This printing process, however, calls for polymer powders with a particle size of around d90 = 100 μm. Cryogenic comminution is one method applied for the production of such fine powders. In this case, polymer granules are embrittled by means of liquid nitrogen (LN2) and then ground in a pin mill. The specific consumption of liquid nitrogen is a major cost factor. Hosokawa Alpine offers solutions to reduce this. Assuming an efficient classifier and mill exist in circuit, the product specifications can also be guaranteed and the operating costs minimised.

Cryogenic size reduction

The feed material must first of all be embrittled to enable cryogenic comminution. To this end, it is cooled in a screw cooler charged with LN2 to a temperature of around -190 °C. The residence time in the screw cooler is selected such that the granules adopt this temperature right into their core. In order to make as efficient use of the liquid nitrogen as possible, LN2 is constantly introduced into the granule bed along the entire conveying line. After being embrittled, the feed material is comminuted in a pin mill. The Hosokawa Alpine Contraplex wide-chamber mill CW 250 II is ideal for this task. The CW-II product line has been given a substantial redesign to make it fit for the demands posed by cryogenic size reduction of difficult feed materials. Two contra-rotating pin discs rotate in the mill at speeds of up to 120 m/s each at their outer periphery, allowing relative speeds of up to 240 m/s to be realised. To compensate for the energy input caused by comminution, liquid nitrogen can be injected into the inlet area of the mill for further cooling.

Optimised screw geometry

As a result of the LN2 injected, the mill outlet temperature can be regulated to a constant target temperature. This is important to ensure that the temperature of the feed material in the grinding zone is always significantly less than its glass transition temperature. Over and above this, it serves to prevent product deposits. Depending on the type of polymer, the standard temperature setting is between -20 and -50 °C. In the case of PA-6, it has been established that an increase in the mill outlet temperature from the standard -40 to -10 °C suffices to prevent the particles from starting to melt in the mill. The resultant lower LN2 consumption naturally has a positive effect on the operating costs.

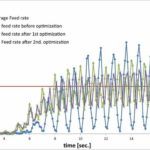

With regard to the specific operating costs, cryogenic grinding is at its most efficient when the mill is charged with a maximum feed rate until the rated output of the mill drive is reached. Homogenisation of the product discharged from the screw cooler helps to avoid performance and/or current peaks. The feed material dosing can be adapted for higher throughputs without running the risk of high feed rate fluctuations, which would lead to undesirable current peaks and in the worst case bring production to a halt. Research projects aimed at optimising the product discharge by means of design measures on the screw cooler were carried out with the aid of DEM simulations and subsequently tested successfully at the testing centre. The greatest effect with respect to homogenisation was achieved by modifying the screw geometry at the outlet of the screw cooler.

Adaptation to the pin discs

Further optimisation of the operating costs is possible by aligning cryogenic grinding with the screening or classifying step, insofar as the target fineness cannot be achieved without downstream classifying. During grinding, the highest possible throughput of finely ground product – for example, less than 100 μm – should be generated and presented to the classifier. In principle, this enables a higher yield of end product. To this end, the design of the pin discs can be adapted accordingly and the mill operated at full load. Amongst other things, these modifications can include changes to the number and dimensions of the impact pins. By reducing the number of pins, the no-load power decreases and the feed material can be charged to the mill at a higher rate. The lower stressing frequency leads to a somewhat coarser particle size in comparison. In spite of this, a higher throughput of fines smaller than 100 μm is nevertheless possible. Compared to just cryogenic grinding with the CW 250 II, the specific operating costs are moreover lower if the feed rates are higher.

Intelligent system concept

It is often only possible to produce polymer powders with the target specification d90 = 100 μm by means of a downstream classifying step using a screen or air classifier – or both processes in circuit with automatic return of the coarse material. Assuming an intelligent system concept for a circuit process, the liquid nitrogen that evaporates during cryogenic size reduction is perfect for direct use as circuit gas for the classifying step. This does away with the need for gaseous nitrogen, which would otherwise be required for the inert mode of operation. Routed in circuit, the nitrogen gas is free from moisture which could condense on the particle surface. This ensures that no additional conditioning of the gas is necessary for classifying. Agglomeration is prevented in this way.

At a constant sharpness of cut of the classifier, the throughput of the end product is higher the finer the material. As a result of the improved fines yield, a correspondingly small amount of coarse material needs to be returned to the grinding process. The lesser amount of circuit material therefore has a positive effect on the total operating costs of the grinding and classifying circuit. Tests have shown that there is an optimum fineness at which the specific operating costs for the manufacture of polymer powders with a d90 of 100 μm are at a minimum. For the tested PA-6, this results in an optimum operating point for the CW 250 II at which the generated fines portion 100 μm is around 65 %.

Online search: cpp0319hosokawaalpine

Hall 16, Booth D6

Authors:

Dr. Ergün Altin

Senior R & D Manager, Technical Division,

Hosokawa Alpine

Dr. Steffen Sander

Head of R & D, Technical Division,

Hosokawa Alpine