The chemical industry manufactures a large number of products for use within the food chain, e.g. vitamins, silicates, oxides, food colourings, etc. Products coming in contact with synthetic filter media during various phases of production must fulfil EU and FDA requirements.

The authors: Peter Lohse Product Manager, Heimbach Filtration Dr. Bert Gilleßen Head of Product Development, Heimbach Filtration

Quality demands relating to the composition and inertness of filter materials are governed by European law, mainly by the European Union Regulations 1935/2004 and 10/2011. Multinational companies may also have to comply with regulations of the US Food and Drug Administration (FDA). For particularly critical applications, such as the production of baby food or pharmaceuticals, a filter media with a bisphenol A concentration level below the detection limit has now been developed. The production of food grade filter media (Figure 1) is carried out in line with HACCP principles and DIN 15593 (hygiene management).

During the production of food additives, textile filter elements are used for product recovery as part of various process steps. The filter media employed for this purpose normally consist of synthetic fibres such as polyester. Depending on the operating conditions, the contact time between the medium and the food additive can vary from a few seconds to several weeks at temperatures from ambient to 250 °C. The filter cake which generally forms is in direct contact with the filter medium (Figure 2).

European Law and FDA

The use of synthetic filter media for contact with products within the food chain is gov-erned by European law. European Regulation (EC) No. 1935/2004, also referred to as the “framework regulation”, deals with general requirements pertaining to health, food composition and organoleptic properties. It also contains guidelines on compliance, traceability and labelling. Regulation (EU) No. 10/2011 came into effect on May 1, 2011. It includes a positive list of monomers and additives which may be used for plastics with intended food contact (the so-called “Union list”). At the European Union level only these approved substances may be used in the manufacture of plastic materials and articles for food contact. Furthermore, threshold limit values are defined for overall and, if applicable, specific migration. The limit for overall migration is 10 mg/dm2 (plus an analytical tolerance). Suppliers issue a declaration of conformity with respect to both the positive list and the threshold limit values. The content of this declaration is defined in Annex IV of Regulation 10/2011.

In the USA, the provisions of the Food and Drug Administration (FDA) apply. They are similar to European Union law as regards positive lists, migration threshold limit values and restrictions on use.

Food grade filter media

Heimbach Filtration presently offers food grade filter media and elements made of polyester, polypropylene and PTFE – including the sewing thread used for the seams. A food grade polyphenylene sulphide filter medium will be available soon. Many different designs and finishes can be supplied: singed, glazed, calen-dered, oleo / hydrophobic impregnated, antistatic or with a PTFE membrane for reliable removal of very fine particles. The product line covers a broad range of chemical resistances and is rated for temperatures up to 250°C. The filter media are required at different points within the food chain, for example to produce milk powder, silicates or colourings. Textile properties such as surface weight, air permeability and tear strength remain unchanged. The food contact suitability of the stainless steel parts used in a filter element (sealing and snap rings) is confirmed by an inspection slip according to DIN 10204 2.2.

Production according to HACCP

HACCP (hazard analysis and critical control points) is a risk analysis method that involves defining action plans for all critical steps within a production process. It was initially implemented in the food processing industry but now increasingly also encompasses the production of food additives or other products with food contact. DIN EN 15593 “Packaging – Management of hygiene in the production of packaging for foodstuffs – Requirements” forms the basis of work instructions for the manufacturing food grade filter media at Heimbach. A clean product flow and processing as well as monitored air quality and cleaning regimes for machines and contact surfaces all contribute to the reliable production of these media.

Migration testing

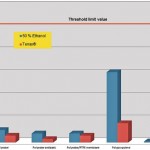

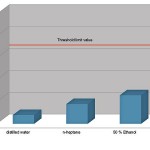

There are established test standards and procedures for measuring migration. Among the test simulants standardised by EU 10/2011 are 50 % ethanol by volume and Tenax (a modified polyphenylene oxide with a large inner surface). Testing according to FDA standards, for example for polyester, comprises extraction with distilled water, 50 % ethanol by volume and hexane followed by the determination of the chloroform-soluble portion of these extracts. 2,2-bis(4-hydroxyphenyl)-propane (bisphenol A) was determined by means of HPLC after extraction in 95 % ethanol.

All measurements were performed by an independent research institute according to current test standards. Figure 3 (data from measurements based on EU Regulation 10/2011) and Figure 4 (data from measurements based on FDA regulations for polyester) show how Heimbach has developed a line of food grade products that are suited for a broad range of varying requirements within the food chain. Providing the raw materials and production processes are selected with care, the migration values recorded for Heimbach filter media are well below the threshold limit value of 10 mg/dm2. Heimbach media also guarantee compliance with FDA demands. Determining migration using 50 % ethanol by volume is a “worst-case” scenario. Testing with Tenax as a dry simulant corresponds to actual contact conditions, including the polymer-specific test temperature, as laid down in the standard.

The specific migration threshold limit value for 2,2-bis(4-hydroxyphenyl)-propane (bisphenol A) is 100 µg/dm2. The concentration in the polyester filter media analysed was less than the detection limit of 0.5 µg/dm2.

cpp-net.com/0312443

Share: