The Fluitec CSE-X mixer is designed for applications that have to meet very exacting requirements. From gasification through homogenisation to mixing processes involving extreme viscosity ratios, the CSE-X has become the system of choice over the years. The CSE-X/4–09 mixer model combines a low resistance factor with optimal mixing efficiency, opening up a wide range of applications. It reduces the pressure drop by around 60 % without compromising mixing performance.

Alain Georg, Daniel Altenburger, Tobias Vögeli

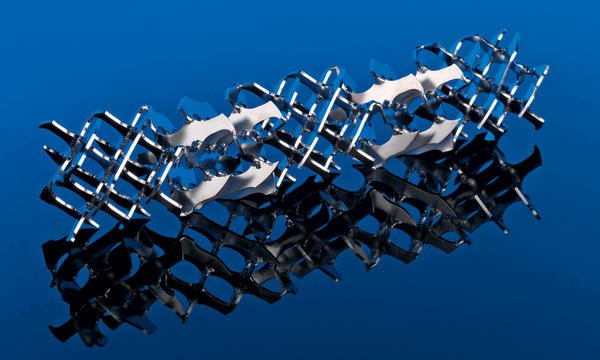

The CSE-X mixer consists of bars mounted crosswise such that they fit into one another. It is made up of several elements, each offset 90°. The number of bars de-pends on the mixing task and the mixer diameter. Most CSE-X mixers have 4, 6 or 8 bars. CSE-X mixers with a large number of bars require a corresponding number of welded joints, resulting in a higher price for the mixing elements.

Fluitec specifically analysed the mixing efficiency of elements with four bars for this reason. Internal tests revealed that with small diameters the number of bars has virtually no influence on mixing efficiency. However, the pressure drop can be reduced by up to 60 % for the same diameter if the bars are also waisted. In addition, the CSE-X is manufactured today using a novel process that is explicitly designed to bring down the production costs for small diameters <DN 50.

Efficiency and pressure drop

The quality of a mixing process at laminar creeping flow is mainly a function of the volume flow ratio of the two soluble liquids. Additional parameters such as viscosity ratios, shear rate, residence time and Froude number are taken into account with the help of complex software tools. Fluitec normally uses the variation coefficient CoV to define mixing performance. Detailed design principles are described in Fluitec Documentation No. 11.030.

The following formula applies to a static mixer installed in a tube in the laminar flow regime:

ΔpL = 32 z h v L/D2

The z-factor and the relative length L/D are generally used to compare the pressure drop of static mixers with an identical diameter and a variation coefficient CoV = 0.01. The resistance in the mixer can thus be determined as follows: resistance = 32 x z-factor x relative length for an identical diameter, concentration and degree of homogeneity.

The mixing performance is shown by the comparison of CSE-X mixers for a concentration of 1%: a CSE-X/4–09 DN50 mixer with four bars and a relative length L/D of 17 has a z-factor of approx. 13.1 and a calculated resistance of 17 x 32 x 13.1 = 7126. The CSE-X/8 DN50 mixer with eight bars and a relative length L/D of 15 has a z-factor of approx. 35 and a calculated resistance of 15 x 32 x 32 = 16800. To achieve a comparable mixing efficiency, the CSE-X/4–09 mixer with 4 bars requires only two mixing elements more than the CSE-X/8 mixer yet generates an approximately 60 % smaller pressure drop. The lower energy input and superior mixing performance were what persuaded Fluitec to focus on the CSE-X/4–09 mixer for small diameters. Larger diameters with six, eight or ten bars can be supplied on request.

Residence time distribution

CSE-X mixers are notable for their high mixing efficiency and short installation length. Numerous tests have confirmed the CSE-X mixer’s optimal residence time distribution. The mixer behaviour approximates an ideal plug flow regime. This is an indication of good self-cleaning efficiency, which is especially important in hygienic applications. Tests were carried out using glucose syrup with various viscosities from 10 to 400 Pas. Whereas in the empty tube additives still adhered to the wall, they were no longer visible in the CSE-X mixers. Bodenstein numbers >100 were not a problem.

Online-Info www.cpp-net.com/2210427

Share: