Every powder or granulate has its own special property profile. How well a system is adapted to this profile is crucial for the efficiency of the process as well as for the quality of the final product. Frewitt recently put an expanded test facility into operation. This facility simulates the customer’s in-house process reality precisely and monitors the product quality. It can be used by the client to test bulk material, optimise processes or develop a new system concept.

The author: Claude Lefebvre Business Development Director, Frewitt SA

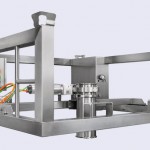

The greater the diversity of the products, the more important modularity becomes: hard, soft, abrasive, fibrous, crystalline and heat-sensitive products must be ground, fluidised, conveyed, metered, weighed and emptied into a wide variety of containers in open or closed systems at the Frewitt test facility. The facility currently up and running at the Frewitt Tech Center consists of modules that are easy to integrate or exchange.

The product is gravimetrically fed into the system via a hopper and a vacuum conveyor (transport module). The ProFi-Sword module ensures continuous discharge. The product then flows downstream from the discharge device and passes through the metering module. The ProFi-Dos metering gate is recommended here for products with poor flow properties. The ConiWitt, TurboWitt and HammerWitt-Lab mills or the ProFi-Accurate metering device can also be used, depending on the product properties and the process requirements. The ProFi-Liner (in-liner) or the ProFi-Bant (pneumatic) and ProFi-Lun (manual) bag clamps are suitable filling elements.

Precision and dependability

This section could easily be entitled ’Consistently high product quality’. The GMP regulations with which the client must comply when processing products are key factors. These regulations may stipulate particle-free, low-germ or even germ-free cleaning. Compliance with the strictest quality criteria is therefore essential for mechanical processes, notably milling and sizing. In addition to fulfilling the quality criteria and process specifications, it is important to prevent contamination. Frewitt’s expanded test facility is designed to ensure that all these aspects are considered.

Accurate results must be guaranteed during the product processing, analysis and assessment phases. Precise modular milling, metering and weighing systems adapted to the prod-uct properties ensure consistently high prod-uct quality. The material to be milled is analysed in Frewitt’s in-house laboratory, an integral part of the company’s Tech Center. The angle of adhesion, bulk density, angles of pitch and repose and granulometry are pre-tested in the powder analysis. The information provided by these parameters allows Frewitt’s application experts to recognise key characteristics of the test product.

The process parameters also need to be evaluated in order to make the process predictable. Frewitt employs statistical experimental design as a means to this end. Complex sets of data are combined, analysed and finally interpreted by application experts in order to filter out important information from which cause-effect relationships can be discerned. The menu controlled software covers three process analysis phases:

- In the screening phase, factors influencing the process are detected while non-relevant factors are ruled out.

- In the modelling phase, influencing factors from the screening phase are challenged by testing and the number of key influencing variables is reduced to those which impact the process.

- In the final optimisation phase, the key factors are precisely replicated and the target values defined.

Using this methodology, the interaction between the process parameters and the target values can be determined, for example, for the ConiWitt conical sieve mill by defining the rotor type, rotor speed and sieve type parameters and selecting three target values: flow rate, particle sizes and temperature change. On the way to meeting product and process specifications, the guide containing the analysis results is an invaluable aid for the client when selecting characteristics and carrying out an initial analysis of process assessments.

Just one small step towards production

A few test series on the facility suffice to give the customer all essential data for optimising an existing system or basic information for designing a new one. The Frewitt concept also offers another major advantage: anything from laboratory or small production quantities (0.5 to 200 kg/h) to large volumes with flow rates >5000 kg/h can be processed on the same facility. Only a small number of simple adjustments are required to convert the test facility from a laboratory system equipped with a HammerWitt-Lab to a mid-size industrial system with a ConiWitt or from one of these two configurations to a high-volume line with a TurboWitt rotary sifter.

The disagglomeration, homogenisation, grinding, pulverisation and sizing processes can all be integrated in the milling area. Due to the different sieve mill designs (rotary sieve drum, one-sided rotor etc.) and the wide range of rotor and sieve types, nearly all powders and granulates can be processed on the Frewitt test facility, which is also suitable for viscous, sticky, heat-sensitive and hygroscopic products.

Hall 3.1, Booth F3

cpp-net.com/0212436

Share: