The powder mixture is primarily composed of talcum powder, colour and effect pigments and mica powder. Further components such as powdery or liquid binding agents are added to make these powders compressible and extrudable. Adhesion promoters ensure that the powder remains on the skin all day long until the make-up is removed. Colour and effect pigments have a tendency to agglomerate due to their fineness. If they are not sufficiently well distributed in the powder matrix, they can leave coloured stripes when applied to the skin. The mixing step must therefore be performed with a lot of shear energy. The challenge in the mixing process is to distribute the components as homogeneously as possible so that they are deagglomerated, in order to achieve a reproducible colour and a fine-powdered end product. Other components create opalescent and holographic effects and must be added with particular care.

High mixing quality fast

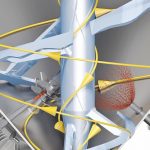

Such multi-step operations are guaranteed in the Amixon mixer by the zero-clearance circulation. A patented Sinconvex mixing tool rotates in the centre of the mixing chamber. The helical blade collects the mixture at the edge of the chamber and carries it upwards. When it reaches the top, it flows downwards again in the centre of the vessel. The components are optimally mixed at a slow rotational speed irrespective of their particle size, bulk density and flow properties. Technically ideal mixing qualities, which cannot be improved any further in practice, are achieved after about 40 to 160 revolutions of the mixing tool. High-shear blades are used in the Amixon mixers to avoid agglomerates. They protrude laterally into the mixing vessel and work at speeds of up to 3000 rpm, deagglomerating, breaking up lumps and activating the surfaces.

The cutting rotors also support the next step in the manufacture of cosmetics: the ultra-fine distribution of the liquid binding agents. The use of cutting rotors enables liquid additives to be homogenised particularly effectively. Highly viscous liquid additives can be distributed into the powder. They are injected below the filling level, directly into the operating area of the cutting rotor, using a feeding lance. The distribution of the fluid thus takes place immediately due to vortex, friction and centrifugal effects when the energy input is increased. The lance can optionally be equipped with a nozzle and tempered if desired.

Discharge rates of up to 99.8 %

Following a short post-mixing time, the manufacturing process in the mixer is complete. The mixing chamber is completely discharged without de-mixing. In practice, discharge rates of up to 99.98 % or more can be achieved under ideal conditions. Finally, automatic wet cleaning can be carried out using the patented WaterDragon system.

The requirements for a preparation mixer are always determined by the individual application. Amixon has over 30 different test mixers, vacuum dryers and synthesis reactors available for test trials, ensuring optimal results. All apparatus have a hygienic design and meet EHEDG, GMP and FDA requirements.

Online search: cpp0218amixon

Hall 6.0, Booth C76