The bioplastic polylactide (PLA) is usually produced through polymerisation of lactide. The starting material for this process is lactic acid, which is produced through the fermentation of sugar. Sulzer Chemtech has developed a method in which the lactide can be purified through melt crystallisation. One advantage of PLA is its versatility given the ability to engineer its properties so that it can biodegrade quickly or, alternatively, remain functional for years.

Manfred Stepanski, Manfred Wäckerlin

Bioplastics are a relatively new class of materials that are produced from renewable raw materials. Manufacturing, utilisation and recycling of bioplastics form a nearly CO2-neutral cycle. According to industry estimates, bioplastics could replace about 5 to 10 % of plastic on today’s market, although today they only have a market share of substantially less than 1 %. Market development depends primarily on two factors: the high price of petroleum and the obligation to reduce CO2 output.

Polylactide (PLA) has proven itself for many years in the medical sector. Screws, nails, implants, and plates made of PLA are used to stabilise bone fractures, as it can be reabsorbed by the human body. Meanwhile, PLA, a clear substance, has become a widely used bioplastic. It has properties similar to those of conventional mass-produced thermoplastics and thus can also be processed using existing equipment. The raw material has potential, above all for short-lived packaging such as drinking cups or food bowls. One disadvantage of the material is its low heat resistance with a low softening point of approx. 60 °C. However, using new types of processes currently in development, it is possible to manufacture PLA with improved temperature stability, after which the material is suitable for drinking cups for hot beverages or as an artificial fiber for clothing and home textiles.

Continuous processes already exist for manufacturing PLA from glucose (sugar) by way of the intermediate steps of lactic acid and dilactide. At the moment, Sulzer Chemtech is working on the development of an industrial polymerisation process, which makes it possible to produce PLA competitively in relation to conventional plastics in the medium term. In the USA, there is already a similar plant in operation with a capacity of 140 000 t/a. In this process, PLA is produced through polymerisation of lactide, a ring-type union of two lactic-acid molecules.

No solvents needed

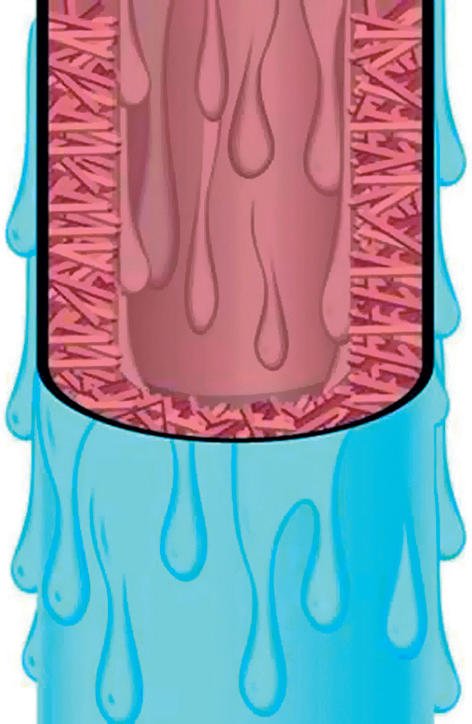

Pure starting materials are an important prerequisite for manufacturing a high-quality polymer, i.e. a transparent plastic with a high molecular mass and rigidity. Lactic acid can be produced through the fermentation of glucose with the help of suitable bacteria. Lactic acid must then be separated from the dregs of fermentation so that they are available as pure raw materials for polymerisation. Sulzer Chemtech’s melt-crys-tallisation process purifies the lactide mixture without the use of solvents. In the process, contaminants are removed that cannot be separated by other methods. High product purity and yield are attained by combining static and falling-film crystallisation processes. The falling-film crystalliser contains vertical pipes that are cooled under controlled conditions. Inside the pipe, cooling causes a layer of lactide crystals to form from a falling film of melt. The crystals reject most impurities which concentrate in the remaining melt fluid. After crystallisation, the impurities that remain in the crystals are removed by warming the layer just under the melting point of the lactide crystals. This step is called sweating. After sweating, the temperature is increased again in order to melt the crystals. Through several repetitions of this procedure, it is possible to obtain lactide that is more than 99.9 % pure. This crystallisation process has already been successfully used for purifying chemicals employed for conventional plastics such as polycarbonate and polyurethane. The crys-tallisers contain no moveable parts such as stirrers or filters thus making the equipment very reliable. The purification process consumes minimal energy, as the operating temperature is comparatively low.

Plant in operation

Sulzer Chemtech’s first lactide crystallisation plant has already been in operation for several years. In view of the increasing demand, the division expects further expansion of production capacity for plastics made from renewable raw materials. Melt crystallisation is expected to be used as a purification method when producing bioplastic due to its environment friendly nature. Sulzer Chemtech is also spearheading developments for other process steps when it comes to manufacturing bioplastics. Besides melt crystallisation, the company offers numerous additional products for manufacturing bioplastics. Distillation columns that are equipped with the packing MellapakPlus are used in producing lactic acid or lactide. MellapakPlus permits high product throughput with low pressure loss and hold-up and thus guarantees gentle handling of temperature-sensitive products. In addition to using distillation separation procedures for lactic acid, the division develops processes for polymerisation of PLA in mixer reactors in cooperation with a leading industrial partner.

cpp 425

Cristallization

Packings

American Institute of Chemical Engineers

Share: