With the Flat Panel Airlift Photobioreactor, algae biomass can be utilised on an industrial scale by exploiting solar energy. Numerous valuable substances such as fatty acids, proteins, vitamins, carotinoids, and colorants can be produced in this way. Furthermore, integrated cycle processes also enable biomass to be utilised for energy.

Stefanie Seidl

Although microscopically small and barely visible, microalgae open up versatile possibilities for use as a supplier of valuable substances for the production of dietary supplements or cosmetics. As biodiesel, the algae biomass is used for energy generation. Not least, algae bind ten to fifteen times more CO2 than forest flora and thus significantly contribute to environmental relief and protection. Subitec GmbH took advantage of all these potentials in the development of its technology. With the worldwide patented FPA (Flat Panel Airlift) Photobioreactor, this Fraunhofer spin-off manages to produce algae biomass with a net energy surplus.

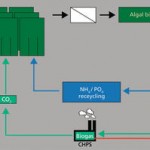

“In our FPA reactors, algae are cultivated utilising solar energy and industrial carbon dioxide to eventually gain numerous valuable substances“, says Dr. Peter Ripplinger, General Manager of Subitec. “Fatty acids, proteins, vitamins, carotinoids, and colorants are then used as starting substances in the chemical, pharmaceutical and food industries“. The algae biomass is employed to produce not just resources but also energy. For this purpose, Subitec develops integrated cycle processes that use the waste CO2 from industrial combustion processes to cultivate algae. After extracting the resources, the remaining biomass can be fermented to biogas. It delivers electricity and heat in a combined heat and power plant. The waste CO2 that is released can be fed back into the cycle process for algae production. The waste from one plant thus serves as a source of supply for another. This closed system permits the circulation of water and nutrients; the biomass ref-inery concept supports total recycling of the algae biomass.

Closed system

The Flat Panel Airlift Reactor meets the requirements for commercial mass production of microalgae in open land. Microalgae and their substances can therefore be used on an industrial scale.

Whereas in Asia, algae are predominantly cultivated in open ponds, the Subitec algae bioreactor allows land-based cultivation in closed bioreactors that are also suitable for sterile operation – an essential prerequisite for the pharmaceutical and cosmetics industries. Under these controlled conditions, algae biomass can be produced continuously, at low cost and in an environmentally compatible way.

Another advantage over the traditional shallow pond concept is the ten times better space-time yield and significantly higher cell concentration within the FPA reactor. Thus, in relation to the algae biomass produced, less energy input is required in an FPA reactor than for cultivation in so-called open-pond systems, which also have a very high evaporation rate. The technology enables algae biomass to be produced with a net energy surplus.

One problem that had to be solved by Subitec was the algae’s uneven exposure to light. In a plate reactor cross-section, three zones of different light intensity can be identified. Directly at the surface, the light intensity is so high that photosynthesis activity is inhibited (photoinhibition). The thin layer that follows is characterised by optimum intensity for algae growth. Fi-nally, in a non-stirred reactor, the culture is in its own shadow and subject to light limitation.

The solution here is to install static mixers to force the directed transport of the cells: Rising gas bubbles are diverted and introduce the culture medium into a stationary, circular flow. In addition, the airlift loop reactor principle permits complete stirring of the FPA reactor, resulting in an optimum light supply to all algae cells through the limited layer thickness and targeted flow direction in the reactor thanks to the static mixers. Algae cells are transported to the light and then back into the shaded zone at a frequency of approximately one hertz. The incident sunlight on one side is therefore evenly distributed to all algae cells in the reactor. Additionally, the average light intensity on the reactor surface can be varied by changing the spacing between the FPA reactors in the field.

Flexible expansion

The photobioreactor is deep-drawn from plastic film in the shape of two half-shells, including the static mixers, which are then welded together. The transparent plastic FPA reactor offers ideal prerequisites for the commercial mass production of photoautotrophic microalgae, i. e. feeding only on light.

Due to the cultivation facility’s modular design, the system is suitable for cultivating different species simultaneously and its capacity can be flexibly expanded. The latest FPA reactor features a useable volume of 180, with a surface area of just under 5 m² and a layer thickness of 5 cm. Compared to its predecessor, the energy input has been reduced from 477 W/m³ to less than 200 W/m³. Subitec GmbH plans to add further pilot plants to the two existing units at Hof Weitenau and in Hamburg/Reitbrook by 2011. At least two of these new plants will be set up in greenhouses in Germany. The company is presently also negotiating the construction and operation of pilot plants in the Mediterranean area.

Online-Info www.cpp-net.com/2210423

Share: