The customer is a leading manufacturer of refrigerants, fluoropolymers and silicon-based products in China. Methyl chloride is an intermediate in the production of silicon. It is obtained by reacting methanol and hydrogen chloride. Hydrogen chloride is typically produced by distilling concentrated hydrochloric acid. Due to the corro-sive properties of hydrochloric acid, corrosion-resistant materials such as graphite and PTFE-lined steel are required for such applications.

Increasing costs for the disposal of weak acid are forcing manufacturers to use HCl recovery systems to produce hydrogen chloride. For this purpose, SGL Carbon is implementing a customised system in China that almost fully recovers hydrogen chloride from contaminated acid.

Process options

Extractive rectification is typically applied for the complete separation of hydrochloric acid. Additives such as calcium chloride or sulphuric acid are used to selectively increase the volatility of hydrogen chloride in order to break the azeotrope. One disadvantage of this process is that the addition of the entrainer results in a higher boiling point in the rectification column. Due to the limited temperature resistance of the materials employed, only a lower HCl gas pressure can be achieved. Consequently, the subsequent processing of the hydrogen chloride either requires elaborate compressors or the lifetime of the equipment is reduced. Since such processes can only be operated efficiently with a high salt content, there is a risk of crystallisation when using alkaline salts as the extractive compound. Additionally, impurities such as F-, (SO4)2-, etc. may form salts that result in severe scaling, thus endangering the reliability of the complete system.

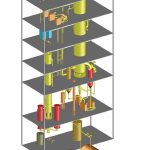

Pressure swing distillation systems avoid these disadvantages since entrainers are not required. They include a pressurised column that generates clean HCl gas free of impurities and entrainer residuals at ele-vated pressure at the top of the column. The azeotropic acid bottoms of the pressurised column is further processed in a second column operating under vacuum. Due to the pressure sensitivity of the azeotropic point, it is now possible to distil water at the head of the column. By using two columns, hydrochloric acid can be split completely into hydrogen chloride and water. One specific advantage of the pres-sure swing distillation system is its very high HCl recovery rate. This is economical with respect both to high HCl yields and to wastewater processing, since the impurity and HCl content in wastewater is increasingly becoming the focus of tightened environmental regulations.

Further design developments

Furthermore, SGL Carbon is gradually going over to carbon fibre composites (Sigrabond Chemical) for the internals in HCl recovery systems. This new material is suitable for use in highly corrosive hydrochloric acid at a long-term application temperature of 170 °C. In contrast to the heavy-walled carbon grids which were previously the norm, the outstanding mechanical properties of the new materials enable grids to be produced with huge free cross-sections that are not subject to hydraulic limitations. This material can also be employed to design distributors with complex geometries, leading to improved liquid distribution on the packing and minimising energy consumption. The superior thermal shock resistance and pseudoplastic fracture behaviour qualify Sigrabond Chemical as the perfect material for the harsh conditions of the pres-sure column.

Material know-how required

Due to the corrosive properties of the medium, it is important not only to consider process aspects in the design of the system, but also to align the process conditions with the application boundaries of the selected material. As a specialist for pressure vessels made of graphite and PTFE-lined steel materials that is also capable of providing complete system solutions in the field of HCl recovery, SGL Carbon combines historical material expertise and process know-how.

Accordingly, the process includes columns and vessels manufactured from the proven material Polyfluron (PTFE-lined carbon steel). This material is characterised by high density and crystallinity, which limits HCl permeation through the liner. Due to clients’ extensive positive experience with weldable PTFE material, a loose liner is used in the equipment, allowing a simpler me-chanical design of the nozzle and correspondingly higher reliability.

The reboilers selected for the process are robust shell & tube heat exchangers made of Diabon impregnated graphite. The tubes and monolithic tube sheets feature Carboguard carbon-fibre reinforcement to ensure maximum operating reliability.

Highly efficient, compact Diabon plate & frame heat exchangers are installed for HCl gas cooling. To minimise the water content, the HCl gas is chilled to double-digit, sub-zero Celsius temperatures. The plate & frame heat exchanger features a design that is corrosion resistant on both the process and the service sides. Hence, the equipment is also perfectly suited as a gas recuperator, utilising the chilled product gas for additional cooling and reducing the running costs. At the same time, the HCl product gas is superheated, which minimises the risk of acid condensation and corrosion in the downstream process.

Thanks to SGL’s HCl process expertise and state of the art materials, the plant is a customised solution that meets the customer’s specific requirements.

Online search: cpp0218sgl

Hall 4.0, Booth F26