A typical application in the cosmetics industry shows how filtration units can be upgraded without having to be completely rebuilt. When depth filter cartridges and pleated elements were integrated into the existing bag filter housings used to filter shampoo, the quality of the filtrate was improved and the service life of the filter extended.

To ensure the purity of the product and separate solids from liquids, bag filters are frequently used as process filters for fine chemicals. Due to their simple operation and high cost efficiency, bag filters are often the first choice when designing the process and planning the plant. Efficient filtration must be assured and the quality requirements satisfied both when the unit is started up and subsequently during operation. Provided the unit is well designed, bag filters are very effective here.

After a while, however, the unit may no longer meet the original requirements. At a manufacturer of cosmetic products, for example, an existing process filtration section for shampoo was in need of optimisation. On the one hand, the product purity requirements had increased. On the other, the service life of the bag filters used up until then was unsatisfactory. The solution that suggested itself initially was to completely replace the existing bag filtration system with one using filter cartridges. This would have entailed modifying the unit and would probably have been very costly. The option of adding more filtration steps was also discussed.

Unfortunately, integrating additional filtration steps into an existing unit tends to be very difficult. Problems can also arise if the conversion to multi-stage filtration with new, additional filter housings to hold the filter cartridges – with better separation rates – is not feasible owing to a lack of space or because the available pumping capacity is no longer adequate. In this case, the entire piping has to be modified.

Wolftechnik took this as the starting point for further deliberations, asking “How can the advantages of depth filter cartridges and pleated media, which must be installed in the cartridge filter housing due to their shape, also be leveraged for the existing bag filter housing so that the unit already in place does not need to be rebuilt?”.

The answer to this question led to a series of new products: firstly, pleated bag filters were developed with a larger filtration area so as to lengthen the service life while secondly, the idea for Wolftechnik’s innovative Lupus II filter media was born. By combining both solutions, it was possible to extend the service life and improve the filtration quality of the cosmetic manufacturer’s shampoo products without any alterations to the unit or the existing bag filter housing.

The filter elements in detail

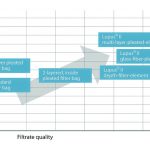

The pleat of the WFB-1AP bag filter prolongs the service life in the same way as a larger filtration area. At the same time, the retention rate is improved by WFB-2IP bag filters, which have two layers and internal pleating.

A quality upgrade is achieved by using Lupus II filter media. Lupus II media for bag filter housings offer not only a high filtrate quality but also a long service life compared to conventional filter bags. These media can be fitted into the existing size 1 and 2 bag filter housings without removing the sieve. Different types of filter media can be supplied depending on the application, namely depth, pleated or multilayer pleated media.

The following filter media are available:

- PP depth filter WFMB (1 to 100 µm nominal)

- PP depth filter WFCP (1 to 100 µm nominal)

- Multilayer pleated element WFMLP (0,3 to 150 µm absolute)

- Glass-fibre pleated element WFGFAW (1 to 25 µm absolute)

WFMLP multilayer pleated elements broaden the field of applications, especially the 70, 90, 130 and 150 µm filter grades. WFMLP filter units with a mesh size of 0.5 or 0.3 µm can be supplied for very fine separation tasks. In addition to pleated bag filters or Lupus II filter media, ferritic metal particles can also be separated using a magnetic rod to further extend the service life.

Application in shampoo production

The optimisation project at the above-mentioned cosmetics company started with a testing phase. Wolftechnik provided the test equipment for this purpose – the filtration expert always has test housings to hand. Any filter media that are not required and are still in the original packaging are taken back, so that the tests are altogether affordable. Cost is always a risk for the user whenever a unit has to be converted, even if simply for testing. However, it is only possible to accurately quantify the effects on the process and the success of the project in real operation.

In the first step, tests were carried out in the existing unit with various kinds of filter inserts in order to determine the impact on the service life and filtrate quality. Since no ferritic particles needed to be separated during the process filtration of shampoo, the test with an additional magnetic rod insert was dispensed with.

The most important criterion for evaluating the tests was the improvement in quality. The costs for filtration in relation to the throughput were also assessed. Lupus II multilayer pleated media produced the best results here.

The unit was successfully changed over to Lupus II multilayer pleated media, which were integrated into the existing bag filter housing. As a result of this, the cosmetics manufacturer was able to meet its own increased quality requirements without incurring any conversion costs and the service life of the filter inserts between individual change cycles was markedly longer. This outcome can be applied to all kinds of products in the chemical industry, for example cleaning agents, body wash and shower gel, cosmetics, hygiene products, plasticisers for further processing in the plastics industry or paints and varnishes

www.cpp-net.com search: cpp0117wolftechnik

Peter Krause

Managing Director, Wolftechnik

Share: