Industrial waste water often cannot be discharged directly into bio-logical waste water treatment plants or surface waterways because it contains toxic, non-biodegradable substances. In such instances, the Fentox process can help:by oxidising non-biodegradable compounds, it converts them into biodegradable products. Industrial-scale Fentox plants are already in operation for a variety of applications worldwide.

Author Jochen Schuhmacher Sales Engineer Water Treatment Technology, Eisenmann

All over the world, legislation on the discharge of industrial waste water into surface waterways or municipal sewage treatment plants is becoming increasingly strict. In Germany, COD consent limits for the chemical industry are defined in Appendix 22 of the German Waste Water Ordinance (AbwV). The reduction in COD that is required before water can be discharged is dependent on the level of contamination present prior to treatment. In addition, local policymakers can define consent limits for specific critical substances.

Conventional biological methods are not sufficient for treating industrial waste water containing non-biodegradable or toxic compounds. As a result, critical waste water streams must be treated separately. The most widely used method is to burn this water – an expensive and energy intensive option. Alternatively, it can undergo wet-chemical oxidation before being returned for treatment with an existing biological process.

One suitable oxidation method is the Fentox process based on the Fenton reaction, as it is simple to operate and features high efficiency and low energy consumption. Hydroxyl radicals, produced under heat in an acidic environment by a reaction catalysed by iron(ii) ions, oxidise the toxins into degradable organic products and/or CO2.

Two-stage oxidation process

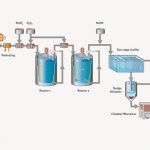

To reduce costs and the consumption of oxidation agents, a sludge filter can be fitted upstream of the Fentox plant. The Fenton reaction begins when iron(ii) sulphate solution and peroxide are added to the preheated waste water. Oxidation takes place in two consecutive stirred tanks. The peroxide levels are topped up as the waste water passes from the first to the second vessel. This two-stage process increases the conversion rate, reduces the consumption of iron(ii) sulphate and slows the formation of sludge. The subsequent neutralisation of the waste water leads to the precipitation of iron hydroxide. This process also precipitates out some of the organic compounds so that they can be removed from the waste water by sedimentation. In many applications of the Fentox process, oxidation and flocculation play an equal role in the elimination of COD. Furthermore, Fentox plants can be easily integrated into existing large-scale facilities, for example upstream of biological waste water treatment.

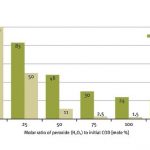

Due to its excellent oxidation capacity, the Fentox process is extremely versatile. It can be used for many kinds of industrial waste water containing a diverse range of substances (e. g. AOX or compounds containing cyanide, arsenic and nitrite). It can also be used to treat col-oured, cloudy or tacky waste water. Fluctuations in the quantity of contaminants are not a problem for this process. The chemical dose can be tailored to the concentration of impurities in the untreated water or to the specific treatment goal (COD reduction or COD discharge concentration). The diagram shows an example of the correlation between COD or AOX reduction and active oxygen (AO) content (the ratio of the peroxide added to the pre-treatment COD in percent).

A large proportion of the cost is due to the consumption of hydrogen peroxide and the dis-posal of sludge.

Large-scale application

Industrial-scale Fentox systems are currently operational for several applications. A South German waste disposal company uses the Fentox process to pretreat 12 m³/h of landfill leachate and toxic waste water from industrial customers. This improves biodegradability in the downstream biological treatment process. Since the level of contamination and the waste water qualities fluctuate considerably, the process must be highly flexible. The Fentox system is capable of cleaning water to discharge quality. Waste water from a pesticide manufacturer is treated using activated carbon filtration following pretreatment in a Fentox plant before being discharged into the Rhine. This system reduces COD and AOX by more than 95 and 99 % respectively in up to 5 m³/h of waste water. In another example, a German silicon manufacturer’s Chinese subsidiary exploits the coagulation and flotation of substances present in waste water during the Fentox process. The recovery of input materials for the production of silicon has significantly reduced operating costs. Moreover, the COD of waste water with an active oxygen content of 10 % is decreased from approximately 20 g/l to less than 1 g/l. The Fentox process is also suitable for treating waste water containing specific, non-biodegradable organic substances. The discharge from a biological waste water treatment plant in a paper factory contains an elevated concentration of a toxic component. This can be reduced by treating the critical effluent stream (1.5 m³/h) separately. With an active oxygen content of only 25 %, the COD content can be reduced from over 35 g/l to less than 0.6 g/l. In addition, the single substance concentration of the toxic component also decreases by up to 99.95 %.

In response to customer enquiries, Eisenmann performs laboratory tests at its R&D centre in Holzgerlingen, Germany, using original waste water samples. This enables the best possible operating parameters to be defined for each system and ensures a safe scale-up. In addition, mobile container-type plants with a capacity of up to 100 l/h are available for immediate implementation on the customer’s site.

Hall B3, Booth 378

cpp-net.com/0114416

Share: