The fertiliser industry is obliged to use efficient, modern methods of production because it faces price pressures and constantly has to meet increasing demands. Plants must be utilised to full capacity and processes automated. High levels of precision and correctly dosed ingredients are a prerequisite of consistent product quality.

Author Wolfgang Götz Sales Manager Light Industries, Schenck Process

The fertiliser industry remains a sector with significant potential. Double-digit sales growth in the Asian and American markets in 2013 compared to the previous year has contributed to the positive mood. China is particularly driving this trend. In recent years, the country has increased the amount of fertiliser used in rice production in order to meet the high demand for food. It has meanwhile become the world’s largest buyer of fertiliser, consuming about a third of the total worldwide production.

The most important criteria for profitable growth on agricultural land are a fertiliser’s so-called NPK elements, namely nitrogen (N), phosphorus (P) and potassium (K). Each of these substances has a specific effect and must be present in the soil in a sufficient concentration. The fertiliser must therefore contain a well-balanced mix. If the proportion of one element is too low, the others will not be utilised efficiently by the crops. The three elements must be combined with ammonia, the most important basic substance used in fertiliser production, in order to be introduced into the soil. Fertiliser manufacturers adopt a variety of approaches here. Some make specific products (nitrogen, phosphorus or potassium) and mix them in defined ratios while others design a complete fertiliser using product mixtures. The outcome of this process is known as NPK fertiliser.

Fertiliser production involves the use of very aggressive chemicals. The equipment and machines are subject to high levels of corrosion, which means they must be carefully constructed using special materials. Corrosion protection is vital. It is also important to avoid ferrous metals in fertiliser machinery and equipment and use only stainless steel in areas where this machinery comes into contact with the product. The plant must have a robust design that incorporates explosion protection.

Consistent dosing

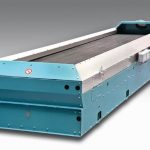

Continuous, consistent dosing is essential in order to achieve the correct proportion of fertiliser ingredients. The Multidos weighfeeder from Schenck Process achieves just that and is accurate to 0.25 %. The precision and function of this weighfeeder, which has its own Disocont electronic measurement and control element, is of central importance. It makes sure even the most difficult dosing tasks are completed successfully and is also very robust. Its simple, well thought-out structure means investment and operating costs are kept to a minimum. It is suitable for continuous measurement and dosing in production systems at feed rates of up to 1500 t/h. The low cost of installation, combined with the small footprint, is a further benefit of the weighfeeder. Its advantages additionally include an automatic conveyor control unit and static belt tensioning by means of integrated spindles. The influence of the belt is taken into account by a belt influence compensation system (BIC), specially developed in-house, which is a great asset in harsh environments. The adjustable hopper function also sets the Multidos apart in terms of flexibility.

Corrosion resistant design

The design of the weighfeeder is fully tailored to the needs of the fertiliser industry. Its drive and frame components are coated to prevent corrosion and the external terminal box is made of stainless steel. The conveyor belt has raised side walls to reduce contact between the product and the machinery. The drive and return drums are likewise subject to corrosion by the fertiliser and are therefore rubberised. All the weighfeeder mountings are enclosed or covered over. However, it is the components in constant contact with the fertiliser that require the highest levels of protection. The cleaning strip at the end of the weighfeeder is cast as a single piece from carbide for this reason. The feed hopper that supplies the material to the weighfeeder is especially made from stainless steel. Large inspection openings allow all components to be replaced quickly and easily. Maintenance is thus more straightforward and downtime avoided. In such extreme environments, easy maintenance provides major advantages in terms of time and cost.

Flow and consumption measurements

Schenck Process also offers other systems for measuring and dosing flows of bulk goods in addition to the Multidos weighfeeder. The Multistream G solid flow meter, for example, is a closed in-line system for continuous mea-surements of bulk goods flows, including fertiliser. It can be used to calculate flow rates and consumption as well as to bill and load a wide range of materials from powder to granulate. The Movemaster corrugated belt conveyor and the Multibelt belt weigher are also very popular in the fertiliser industry along with Proflex vibratory feeders and Mechatron loss-in-weight feeders.

There are basically two demands that must be met by all equipment used in the fertiliser industry: highly precise dosing of the ingredients and an ability to withstand harsh environments. Rapid replacement of individual components must also be possible. Schenck Process has demonstrated that accuracy and robustness are in no way mutually exclusive by offering systems that successfully meet both requirements – and hence the needs of the fertiliser industry.

cpp-net.com/0114443

Share: