In terms of economics, safety and ecology, the focus has shifted away from steel pipes. In practical terms, the alternatives are high-quality plastics that enable filling tanks reliably, even with aggressive or corrosive chemicals.

Sanjay Patel

Tank filling is prerequisite in chemicals manufacturing. Wherever liquids are used in manufacturing, tanks must be filled and emptied. This activity is generally part of a process, such as dilution, mixing, neutralising and batching. All subsidiary systems have a common requirement: the highest possible safety as well as high availability of the system. This is what plant operators need.

Often, the chemicals used are hazardous; some substances, like hydrofluoric acid and chromic acid, are even toxic. For many years, plant operators have relied on thermoplastic piping systems to transport such media. Materials such as PVC-U, PVC-C, PP-H, PVDF and PE are par- ticularly suited to these applications due to their high chemical resistance to media which would otherwise be highly corrosive.

Tank filling in detail

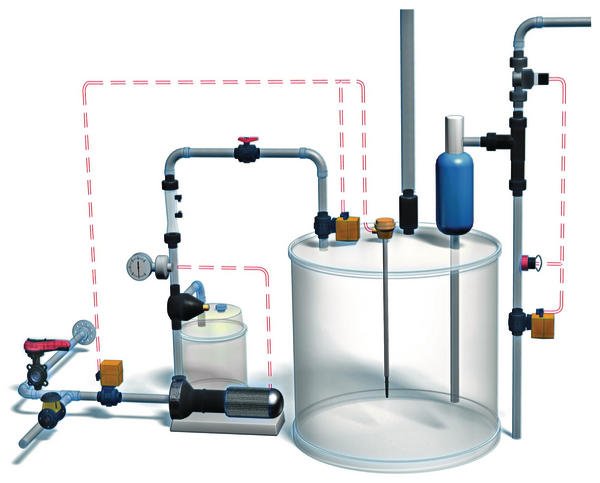

In practice, there are basically two methods of tanking filling: with pump or without. For the latter, compressed air is conducted into the transport tank using a double pipe system. GF Piping Systems has a patented double pipe system on offer, which guarantees a safe medium flow. By means of a vac-uum pump, a vacuum is created in the expansion chamber upside of the tank. The liquid content is extracted via the second pipe, passes through valves as well as flow and fill level sensors; subsequently a solenoid valve is closed in order to prevent backflow. The transport tank is thus emptied without direct use of a pump.

Besides the actual tank, which is used to store liquids, the pipelines to and from the tank and the fittings, as well as other key components are required to complete the tank filling system. GF Piping Systems provides all the necessary components, such as water-jet pumps, aerators, aspirators, level transmitters, flow meters, non-return valves and valves developed and produced in-house. Precision is an absolute must throughout the entire process. Level meters and flow sensors, e. g. those from GF Signet, are important system components, which guarantee the necessary precision.

A feature of plastic systems, which is often appreciated by planners, is the possibility of prefabrication. A tank filling piping system made of plastic is also significantly lighter than comparable constructions in steel. Thanks to the many jointing techniques available for plastics, it is possible to avoid downtime due to dangerous fusion work in sensitive areas, as is the case for steel systems.

Designed to meet requirements

One of the key factors for using plastics in plant engineering is their good resistance to a variety of aggressive chemicals. Liquid media containing electrolytes attack metal materials in the form of electrochemical reactions. Although there is no electrochemical reaction in plastic, other chemical and physical processes are nevertheless possible and must be taken into consideration when selecting the material. It is advisable to rely on the manufacturer’s experience and expertise in recommending the most suitable material, thus ensuring safe operation and a system lifetime of up to 25 years. For the correct selection and dimensioning of pipe materials, valves and measurement technology, the system should be designed to meet the requirements.

Hall 8.0, Booth M16

Online-Info www.cpp-net.com/2209428

Share: