If the Atex directive imposes strict requirements with regard to monitoring, dry-running mechanical seals can quickly become uneconomical. Chetra has therefore developed a mechanical seal called 600MDA, which is positioned, as it were, outside the Atex directive providing certain operating conditions are satisfied.

The authors: Hans J. Rabl, Managing Director, Chetra Heinz Untersehr, Manager Application Engineering, Chetra

Dry-running, single-acting mechanical seals have been in use for quite some time as an economical alternative to conventional, liquid-lubricated or gas-buffered double me-chanical seals for agitators, mixers and reactors with top drives. Since the introduction of the Atex 94/9/EC directive, dry-running me-chanical seals – both single- and double-acting – are subject to strict requirements while in operation with regard to monitoring. The following rules apply in zone 0 (Category 1):

- Single-acting mechanical seal, dry-running, with two types of protection (monitoring systems) and certification

- Multiple (double-acting) mechanical seal, dry-running, with appropriate supply equipment, two types of protection (monitoring systems) and certification

- Multiple (double-acting) mechanical seal, liquid-lubricated, with appropriate supply equipment (barrier pressure vessel/receiver tank and accessories), two types of pro- tection (monitoring systems) and certification

These separate systems monitor parameters such as temperature, pressure and level. A safe distance from the maximum permitted surface temperature is thus ensured. However, the additional capital costs which arise can easily be in four or five figures. Personnel costs are also incurred for the monitoring process along with costs for the required documentation. This includes Atex documentation with an EC type examination certificate or deposition with a European Notified Body as well as periodic inspections.

Economical use under Atex

Apparatus that works with dry-running me-chanical seals is often used in the chemical industry. The monitoring, testing and documentation requirements described above generate considerable additional expense. In order to continue leveraging the technical and eco-nomic advantages of dry-running mechanical seals – compliantly with the safety requirements of the Atex directive – Chetra developed the dry-running, 600MDA single-acting me-chanical seal. This seal guarantees a maximum temperature rise within the permissible limits providing certain operating conditions are satisfied and is thus “outside” Atex, in other words no additional monitoring system (type of protection) is needed. The following were top priorities for the engineers who came up with the 600MDA:

- Optimally balanced seal faces

- Optimised surface design of the seal faces

- Constructional safety

- Material selection

All these considerations were consistently optimised, taking into account the basic technical requirements of a mechanical seal where heat must be restricted to a minimum.

The various design and material approaches were applied to prototypes which were tested extensively on in-house facilities. Temperature, thermal conductivity, pressure balancing, sliding, wear, noise and leakage were the main properties and parameters analysed. Once significant results were available, the Atex department of Bureau Veritas Products Services was charged with carrying out an assessment according to the Atex 94/9/EC directive, subsection 3.7.3. The operation of the 600MDA me-chanical seal in the context of the directive was summarised as follows:

The 600MDA mechanical seal can be operated within the specified limits of use and under the specified conditions in all zones and for all combustible gases and liquids with a gas blanket. Even in the worst case, the mechanical seal cannot exceed a temperature of +68°C. If wider limits of use are defined, the 600MDA mechanical seal is subject to Atex and assigned a temperature class. However, due to its very specific, optimised properties, type of protection c (constructional safety) is sufficient even for zone 0. For details, please refer to Table 1 (Category 1, zone 0) and Table 2 (Category 2, zone 1). The 600MDA mechanical seal series covers the following diameters (DN): 40, 50, 60, 80, 100, 125, 140, 160 and 180 mm.

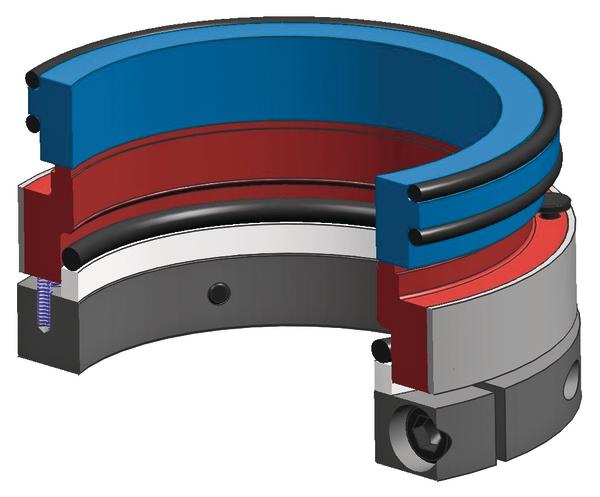

Parallel to the development of the 600MDA single-acting mechanical seal, the 597MDA multiple mechanical seal was evolved as a dry-running double seal in cartridge design. The requirements of the German Clean Air Act (TA Luft) are fulfilled in connection with API plan 72 and 75 or 76. Both the mechanical seals described here allow operators in many applications to leverage the economic advantages of a dry-running seal without incurring extra costs for expensive additional monitoring systems and approvals.

cpp-net.com/0312403

Share: