To evaporate highly flammable solvents economically, a contact dryer must work under inert gas. The mixer manufacturer AVA Huep uses Inmatec’s PSA generators on site at its pilot plant station to produce nitrogen directly. Thanks to the pressure swing adsorption process, high purities of 99.999 % and more are now a reality.

Helmut Huep, Richard Kertsch

Contact dryers are often employed to vaporise explosive dissolvents. If the product is the output of a centrifuge, filter press or suction strainer, the material is often still humid and therefore not free-flowing. To dry it, forced shovel or spiral dryers are employed, in which the product is constantly agitated by the mixer during the drying process. The biggest handicap of this procedure is that the mixer entails a risk of fire and explosion – unless either a controlled atmosphere is created or the velocity is significantly curbed.

It is a known fact, though, that while the danger of explosion is reduced at mixing velocities of less than 1 m/s, most products cannot be dried efficiently at such rates. It takes too long and the product frequently agglomerates irreversibly. In order to achieve Atex compliance, it makes sense to flood the product chamber with pure nitrogen. This is done prior to starting the dryer and filling it with product. During the drying process, the product is also flooded with a layer of nitrogen (between 5 and 30 m³/h). The nitrogen layer enhances the drying effect, as the gas serves as a carrier for the humidity.

On-site production

On-site production of nitrogen is possible, for example, with nitrogen generators from Inmatec. Due to the minimal operating costs, producing nitrogen in-house can easily translate into actual savings of up to 80 % compared to using bottles, bundles or tanks. On top of this, on-site production is absolutely friendly and neutral to the environment because the bottles, bundles or liquid nitrogen no longer have to be transported by van or truck. The initial investment in an Inmatec generator is completely recuperated within one or two years. The company also offers rental and leasing agreements.

Very high purities of nitrogen are required for inertisation purposes (creation of a controlled (CA) or modified (MA) atmosphere). The purer the nitrogen, the lower the risk of fire and explosion or deflagration. With Inmatec’s PSA (Pressure Swing Adsorption) technology, users achieve purity levels of up to 99.999 % or better.

Typical application

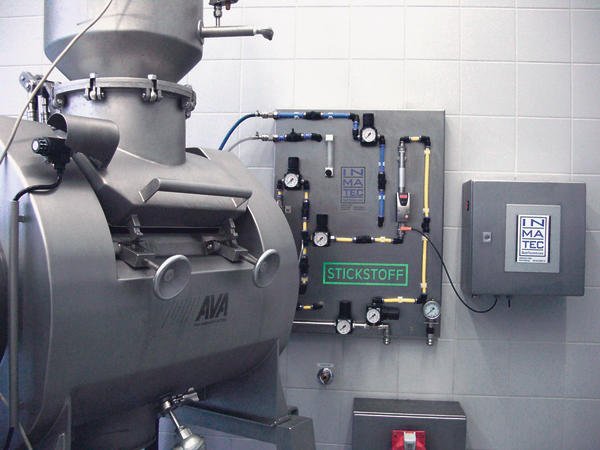

Inmatec fitted AVA’s pilot plant station with a fully automatic nitrogen system. The installation is extremely small – for producing only minimal amounts of nitrogen – and mounted on a wall, from where it supplies a forced shovel dryer with pure nitrogen.

Since the AVA pilot plant station processes products characterised by great diversity, the nitrogen concentration has to be continuously variable from 90 to 99.5 %. All PSA generators are controlled by a WLAN-capable touch control panel (TCP). The customer can thus regulate the flow and concentration of the nitrogen produced, adjust the operating process as appropriate and optimise the consumption of compressed air. AVA can then import this data into its own software tool, so that the required nitrogen amount and concentration can easily be calculated at the end of the trial period.

Inmatec nitrogen generators are equally ideal for producing very small quantities. AVA also uses them in another application for this reason: instead of making all switch cabinets in a pressure-sealed Ex d design, they are filled with compressed N2 atmosphere from the generators – an ingenious way to achieve Atex compliance.

Hall 4.2, Booth P20

Online-Info www.cpp-net.com/2209404

Share: