EHEDG, QHD, 3-A Sanitary Standards, materials specifications of the FDA and BfR (Federal Institute for Risk Assessment) – the list of hygiene guidelines for food conveyance systems is a long one. The background to this is the need to prevent the transfer of any impurities into the product being transported and ensure the most comprehensive cleaning of the equipment possible. Similar requirements are also laid down in the chemical and pharmaceutical industries, which is why special hygienic pumps are now used in these areas, for example the Nemo BH.

The author: Roger Willis Leiter Geschäftsfeld Chemie & Papier, Netzsch Pumpen & Systeme

Firstly, the Nemo BH hygienic pump from Netzsch Pumpen & Systeme has a conveying area which has no dead spaces and is easy to clean. Secondly, only approved materials are used to make it. The underlying progressing cavity technology also means that smooth conveyance with speed regulation is ensured.

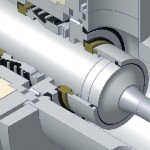

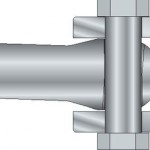

The crucial point in hygiene-critical processes is cleaning the pump. On no account must residues of the medium be left behind in places where they could contaminate the fresh me-dium during later conveyance processes. The Nemo BH hygienic pump was therefore designed to be hydrodynamic and free of dead spaces, so as to avoid any areas where deposits might potentially build up. An open type of construction was developed for the joints which transmit the torque to the rotor. All sides of the connection pieces are accessible and fully rinsed. It is possible to manage without separate lubrication if lubricating media are processed. A variant with a flexible rod instead of joints is however also available as an alternative for non-lubricating materials. Further-more, the surfaces of all parts that come into contact with the product have a polished finish. As a result of this, there are no surfaces to which viscous or sticky substances could adhere. Even for shaft sealing, in addition to a version with elastomer bellows and an optional cutting edge, there is also a model with an encapsulated wave spring and smooth outer contour. Both types are independent of the direction of rotation, so that the conveying direction can be reversed up to the maximum pump pressure without any problem.

The Nemo BH can be cleaned and sterilised in accordance with CIP and SIP principles. To ensure the required minimum flow rate of 1.5 m/s for the cleaning solution throughout the pump chamber during the CIP process, the system is equipped with additional flushing ports and a bypass line. The latter is also a requirement for the more thorough SIP process, in case this is demanded by the application. The pump materials are suited for use at high temperatures and with the fluids normally resorted to in the cleaning processes.

Accurate and smooth

Adverse effects on the system or the medium due to pressure variations or pulsation are prevented by the special operating principle of the progressing cavity pump. A helix rotor with a geometrically adapted stator forms uniform conveying chambers. The funnel-shaped stator inlet ensures optimum filling of these chambers. In addition, the system can be provided with a conveying screw to improve the uptake of material. As the rotor turns, the chambers move from the suction to the discharge side, whereby the pumping capacity can be precisely regulated via the rotation speed. At the same time, pulsation and shear forces are avoided and continuous conveyance is achieved with guaranteed stability under pressure.

There are even two different rotor-stator geometries on offer to enable the Nemo BH hygienic pump to be perfectly aligned to specific applications. The S-geometry is characterised by high entry cross-sections and low flow velocities and is also suitable for conveying lumpy products or large solids. The L-geometry has identical dimensions but double the rotor-stator pitch and can thus handle higher pumping capacities. Due to its elongated seal, it achieves a long service life and good volumetric efficiency. To protect them from dry running, the stators are fitted with a thermal protector which detects a dry pump with one or two sensors and switches it off before any damage occurs.

Multiple certification and flexible use

The maximum capacity of the hygienic pump is 200 m³/h for differential pressures up to 24 bar. The system is suited for a broad range of media from shear-sensitive to abrasive or adhesive materials, including fluids with very high viscosity. For special temperature requirements, the pump housing and stator can also be supplied as a heatable or coolable version. The pump can be installed vertically or horizontally and take up fluids even in largely airless conditions, almost up to absolute vacuum, meaning that conveyance is likewise not a problem in contamination-proof atmospheres. The Nemo BH is manufactured and tested in accordance with EHEDG and QHD guidelines. All materials, particularly the elastomers used, are approved in accordance with FDA regulations. The hygienic pump moreover meets the requirements of several international certificates, such as the US 3-A Sanitary Standards and the Russian GOST-R.

cpp-net.com/0312430

Share: