The concept, design and realisation of central vacuum supplies is one of Busch Vacuum Pumps and Systems’ core competencies. Thousands of such vacuum systems are in operation worldwide. A wide range of operating principles are applied for generating vacuum in the individual pump modules. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry-compressing vacuum modules can be used, for example in vacuum systems with Cobra NX screw vacuum pumps.

The centralisation of the vacuum supply in a plant should be seriously considered if multiple processes or machines require vacuum. Using the Cobra NX screw vacuum pump, Busch is able to configure complex vacuum systems for many applications. These systems are employed whenever absolutely clean exhaust air is required or when contamination between the pumped medium and an operating fluid must be avoided at all costs. This is the case when a house vacuum is generated in research and development departments, laboratories, production areas in the semiconductor industry or areas where hygiene is critical, such as in the pharmaceutical industry.

Individually tailored

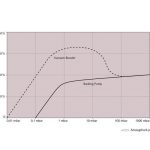

Busch tailors the design of these central vacuum systems to the specific application. The main modules are Cobra NX screw vacuum pumps, whose working principle does not require operating fluids. Vacuum systems such as these can be adapted to the required pumping speed by selecting the appropriate size and number of Cobra NX screw vacuum pumps. By also using vacuum boosters, it is possible to increase the pumping speed and vacuum level cost-efficiently and effectively.

Cobra NX screw vacuum pumps can be used without operating fluids since the moving parts do not come in contact with each other. Two screw rotors rotate in opposite directions in the cylinder of the vacuum pump. The pumped medium is trapped between the cylinder and the screw chambers, compressed and transported to the gas outlet. There is only a very small clearance between the screws and the housing, so that the individual components do not touch. This means that there is no friction, which would otherwise require a lubricant to be used in the compression chamber. The newly developed screw profile and the unimpeded gas discharge ensure even temperature distribution throughout the pump body, leading to a lower thermal load and a longer life cycle.

Economical operation

Cobra NX screw vacuum pumps require a lower motor power per se than oil-lubricated or liquid ring vacuum pumps. A further advantage is that Cobra NX screw vacuum pumps can be equipped with a frequency-controlled motor, which enables demand-driven operation. This can lead to further considerable energy savings as compared with a decentralised vacuum supply. With a decentralised supply, every individual vacuum pump must be designed to meet the maximum demand at the respective consumer.

However, in practice, it is often the case that the maximum power is seldom required simultaneously by all vacuum consumers. The central vacuum system control concept ensures that only the number of vacuum pumps required to meet the demand at a given time are actually in operation. These can be powered down even further through frequency control. Thanks to this dry vacuum technology and demand-driven control, central vacuum systems can achieve energy savings of up to 60 %. In addition to the lower energy consumption, there is also a reduction in operating costs: maintenance is restricted to a minimum due to the contactless operation. Only the gear oil has to be changed every 8500 operating hours or once a year.

Cobra NX screw vacuum pumps are water-cooled. This facilitates the use of pump waste heat. All vacuum pumps can be connected to a common cooling water circuit, for example, and cooled via a heat exchanger, thereby generating warm water for other applications in the plant.

Online search: cpp0219busch