The Simmerring Radiamatic HTS II PTFE shaft seal was developed for sealing stirrers and mixers used in sterile processes and food production. By utilising a split version of the standard Simmerring, conventional stuffing box seals can be replaced in the existing application space. This results in an FDA-compliant solution without any dead spaces that does not require the drive to be disassembled for seal replacement.

The authors: René Minkus Customer Service Director, amixon Christian Geubert Technical Support Europe, Freudenberg Process Seals

The PTFE Simmerring Radiamatic HTS II is characterised by four major advantages:

- It has no gaps owing to the customised sealing lip geometry.

- Its materials are suitable for food processing.

- It is pressed into the housing’s open bore for assembly.

- Its manufacturing process allows different shapes and sizes that can be matched to the application‘s requirements.

Based on this standard Simmerring, Freudenberg has developed a customised solution for amixon’s precision mixers.

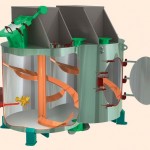

Highest quality mixing

Amixon mixers are precision mixers used for mixing dry, wet and suspended solids. They are also frequently employed as vacuum driers, reactors and sterilisers. In all cases, the appa-ratus produces high-quality mixtures. The product flow is created in a similar way in all of the mixer designs. A centrally mounted mixing device rotates inside the vertical mixer chamber. It produces a three-dimensional rearrangement, in which the product to be mixed is conveyed upwards at the periphery of the mixer and downwards under gravity in the centre. The flow achieved in this mixing process has no dead space and is independent of the bulk properties of the components (different particle sizes, bulk densities, wet components, flow properties, etc.). The resulting mixing quality is a technically ideal distribution which cannot be improved in practice. The circumferential speed of the helical spiral mixing device is freely adjustable and is approximately 0.8 to 3 m/s. This all adds up to a mixing process that is fast as well as gentle.

Replacement for stuffing box packing

Due to the fact that stuffing box seals can be serviced or replaced with little cost and effort, many mixer shafts on amixon and Ruberg mixers have been sealed with them in the past. Stuffing box seals are meanwhile considered to be less suitable because their sealing properties degrade over the machine’s working life in the presence of fine dust and high system pressures. This is not the case with the Simmerring Radiamatic HTS II.

With its sealing lip fitted flush within the prod-uct space, the PTFE Simmerring Radiamatic HTS II was developed especially for FDA-compliant mixer and stirrer designs. The big breakthrough in the development of a solution that eliminates gaps and dead spaces is the alignment of the sealing lip with the product. Since this lip has no spring, there are no gaps or dead spaces and product contamination by microorganisms is therefore avoided. The Radiamatic HTS II sealing lip is designed such that the defined contact surface is approximately constant under all operating conditions. This special lip profile optimises the contact pressure and consequently ensures the sealing function. The lip is compressed elastically during installation and rebounds automatically afterwards. The sealing lip pressure increases along with the application pressure. A rise in temperature helps retain the sealing lip shape. The shaft sealing ring thus guarantees excellent sealing properties, even at high circumferential speeds or high pressures. As a direct result of this, friction and wear are reduced and there are no adverse effects on the working life of the seal, even when running dry or in contact with powders and dust. The standard Simmerring Radiamatic HTS II can be used at linear speeds of up to 18 m/s and temperatures from -70 to +200 °C.

Amixon wanted to leverage the advantages of a lip seal for its mixer range. When lip seals are replaced, an elaborate installation procedure is required, similar to when replacing mechanical seals. The housing or drive has to be removed from the mixer shaft. In addition, there has to be enough free space above the mixer to install the seal. The manufacturer formulated a demanding development objective, namely to combine the spatial and installation advantages of the existing stuffing box packings with the hygienic and long working life benefits of lip seals. The standard PTFE Simmerring Radiamatic HTS II is explicitly designed for open installation spaces and the PTFE body of the seal is machined. These are ideal prerequisites for the desired solution. Thanks to this flexible production method, the lip seal can be customised to specific installation spaces and operating conditions. This represents a crucial advantage when converting mixer and stirrer shaft seals.

The split version of the standard Simmerring also meets amixon’s particular installation criteria. The customised lip seal can be installed inside or outside the mixer space without removing the drive. It is permanently sealed with FDA-compliant materials and resistant to wear, and it can also be installed with ease. Meanwhile, the manufacturer has continued to develop its own machining methods to enable existing stuffing box seals to be converted to hygienic lip seals on older mixers already on site. This service will be increasingly resorted to for converting processing lines with existing mixers, in order to make them lastingly dustproof and compliant with hygienic regulations.

Online-Info: www.cpp-net.com/0311419

Share: