The entire range of Sigma motor-driven diaphragm metering pumps, control type S1Cb/S2Cb/S3Cb, has been thoroughly renewed and provided with additional intelligent features offering a high level of operating comfort, safety and efficiency. All Sigma control type pumps are equipped as standard with a removable operating unit, an automatic excess pressure off switch and a multilayer safety diaphragm.

The author: Michael Birmelin Marketing Editor, Prominent Dosiertechnik

The embedded microprocessor control of Prominent’s redesigned Sigma diaphragm metering pump is an optimum combination of speed control and stop & go operation, i. e. it works in a wide control field with customised fine adjustment. For the first time, the pump control can record any motion and speed profiles in conjunction with power demand. It does this with the help of integrated software that controls the motor electronically. The power demand is identified and the power feed controlled according to the specific requirements of the desired application. This leads to a real reduction in the actually needed power and hence increased efficiency. In total, an energy saving of over 15 % is achieved at full load compared to conventional pump controls, while at half or two-thirds of the full load the saving can be as much as 30 %.

Intelligent motion control

Moreover, the control enables an optimum metering result because the pump’s metering behaviour is matched to the chemical or application. This behaviour is fine-tuned to the prevailing conditions using metering profiles. The series allows variable drive speeds. These in turn permit intelligent motion control, leading to lower costs for energy and optimal support for any application. The stroke movement of the diaphragm pump is continuously measured and controlled, so that the stroke is executed according to the desired metering profile. With a shorter suction stroke and longer discharge stroke, for example, the medium can be discharged more uniformly whereas with a long suction stroke and short discharge stroke, highly viscous media is metered more efficiently.

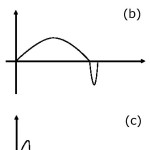

During normal operation the suction and discharge strokes have a similar time characteristic (see diagram). In the mode with an optimised discharge stroke this stroke is longer while the suction stroke is executed as quickly as possible. This setting is useful for applications that require optimum mixing behaviour and continuous chemical mixing, for example. In the mode with an optimised suction stroke, the latter is carried out as slowly as possible to permit precise and trouble-free metering of viscous and gaseous media. This setting should also be chosen to minimise the NPSH value. Sigma pumps can be linked to a higher-level control or operated as independent stand-alone solutions.

Safety as standard

All Sigma motor-driven pumps are equipped with a multilayer safety diaphragm and integrated diaphragm signalling as standard. The diaphragm is coated on both sides with PTFE film to ensure that no leakage occurs to the outside. If the diaphragm ruptures, feed chemical enters between the diaphragm layers and triggers a mechanical indication or an alarm via the sensor area. The structural design of the safety diaphragm prevents feed chemicals from remaining in the dosing head, even in the event of diaphragm rupture, and leakage into the environment is completely avoided.

A visual indication is also provided as standard. If a fault message appears, the user can react promptly to any damage. Even greater convenience is offered by the diaphragm failure indicator on the control version of the motor pump. In this case, a failure is indicated by the illumination of a red LED as well as an error message on the LCD screen. Depending on the setting, the pump either stops or continues to meter with a simultaneous alarm message. This concept guarantees reliable metering – even under critical operating conditions.

Hall 8.0, Booth J94

cpp-net.com/0212402

Further highlights

Achema 2012

Prominent will also be celebrating a world first at Achema 2012 by showcasing its recently developed process metering pump Zentriplex. The completely new construction offers the following key benefits and advantages: compact dimensions, low weight and energy efficiency. Prominent will also present the possible uses of panel-mounted metering stations of the Dulcodos range as well as the high-performing hose pump type DFDa for feed rates of up to 15,000 l/h.

Also in the area of measuring and control technology a world premiere takes place – the measuring and control device Dulcometer dialogue DAC. The controller platform was specifically developed for the continuous measurement and control of liquid analysis parameters. It is used in environmental engineering and industrial processes. The diaLog DACa controller intelligently completes the control circuit between Dulcotest sensors and metering pumps offering special functions, as required in water treatment.

Share: