Closely aligned with user requirements, the generation of diaphragm valves described below is not only reliable and easy to operate, it is also efficient and the volume flow rate (Kv) has been increased. The type of media conveyed is no obstacle. From extremely contaminated or solid-containing to highly pure media, anything is possible. The real technological advances are actually located on the inside of the valve. The optimised, turbulence-free design has doubled the flow rate.

Rainer Kech

Reliability and efficiency in one easy-to-install system – these were the prerequisites for the new generation of GF diaphragm valves. The most obvious feature of these valves is their central plastic thread, which has replaced the conventional four metal screws. The chief benefit here is that the connecting elements are now corrosion-resistant. Not apparent at first glance perhaps, but equally important, is the more homogeneous thermal expansion behaviour, which eliminates the need for retightening. The central plastic thread permits a uniform seat pressure, guaranteeing leak-tightness up to an operating pressure of 16 bar.

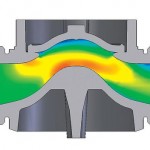

The real technological advances are actually located on the inside of the valve. The optimised, turbulence-free design has doubled the flow rate. The rounded contours with soft transitions and radii mean less abrasion and noise transmission, which adds comfort in daily use. The modified geometry of the valve body results in a linear control characteristic – and therefore also consistently stable processes. The sealing struts of the zero static valve were placed directly in the wall of the through-pipe, minimising dead space while maximising hygiene.

How the design affects the flow rate of the diaphragm valves can be seen exactly in an independent comparison in which the new valves were tested against conventional diaphragm valves. 100 % more flow was achieved on average with the optimised, turbulence-free flow contour. In the long term, this contributes to the economic efficiency of the valves through lower running costs and a lower overall cost for media transport.

Optimised flow rates translate into a more economical valve because it is more efficient. The flow can be controlled more precisely and the overall control dynamics of the valve are more stable. Added to this are the higher chemical resistance of the membrane material, a specially developed FPM, and a longer service life thanks to the greatly reduced abrasion. The pressure losses over the period of use are considerably lower, while buckle and crack formation is practically non-existent. The soft transitions in the sealing struts delay wear. These features combine with the engineered details of the diaphragm valves, such as the centrally threaded valve housing and the membranes, to render them more robust, more reliable and easier to use in daily production applications. An optimised flow rate ultimately means that pressure loss is lower and energy is saved, which in turn reduces the running costs.

Colour coding

Aligning valve features with user requirements begins with attention to detail, such as colour coding for the pressure rating (on the housing nut) and the diaphragm material (coloured indicator on the housing). A wide variety of materials require the valves to be compatible with the processes in which they are used, in order to guarantee safety. Valve bodies can be made from PVC-U, PVC-C, ABS, PP-H, PP-n or PVDF and membranes from EPDM, PTFE, FPM or NBR. This range of materials covers almost the entire spectrum of chemicals with which the diaphragm valves can come into contact. The diaphragm interface is designed so that the closing forces are evenly distributed over the whole sealing surface, thereby preventing compression forces from being applied to the threaded joint. When the valve is opened, the pulling force is transferred to the joint.

A two-coloured position indicator on the manual valve shows the valve’s current position and is clearly visible even from a distance. The enormous diversity of connection options means that the valves can be used universally. Compatibility, in this context, refers to the global standards for connections: ISO, BS, ASTM, ANSI and JIS as well as prEN SO 16138, ISO 9393 and EN 558 have all been taken into consideration.

Operating principles

Standard versions of the diaphragm valves are operated manually via an integrated, lockable handwheel, which protects against inadvertent manipulation. An optional, self-adjusting, electrical feedback unit, installed in just a few simple steps, enables automatic control and regulation of piping systems as well as reliable process monitoring.

The valves can be automated with Diastar, the pneumatic valve actuator. Thanks to the three different pressure categories – Diastar 6, 10, and 16 for 6, 10 or 16 bar respectively – the pneumatically operated diaphragm valves are quickly and easily integrated into virtually any piping system. The round design of the valve means that the air connections can be turned to the desired position in 90° increments. Integrating the valves into the system control concept is no problem with the corresponding interfaces and the wide array of accessories, so that individual solutions are always possible. The outside and connecting dimensions of the predecessor models have not been changed. All the new valves are therefore downward-compatible and can be installed in an existing pipeline.

Online-Info www.cpp-net.com/2210400

Share: