Time-proportional control has been available for a long time, but is often overlooked by process control experts who tend to utilise more sophisticated PID algorithms, often with self-tuning or other enhancements, even when they’re not actually necessary. While there is a place for these, the simpler time-proportional control algorithm should not be forgotten. It uses lower-maintenance components to achieve improved control in many applications.

Author Lori McPherson Regional Sales Manager, Walchem

Unlike traditional proportional or even PID control systems that require a varying output to a modulating control device, time-proportional control can achieve a proportional control response to process variations using an on/off device by varying the on and off times in a defined control period. The on/off device is generally simpler and less expensive.

There are two common types of proportional control. The first utilises a proportional ana-logue output signal (4 to 20 mA) while the second employs a proportional pulse output signal. There is also a third, often overlooked possibility that can provide proportional control solely with an on/off device. It is referred to as time-proportional control. Time-proportional control is a very cost-effective method for achieving tighter control of a process compared to on / off control, which may offer additional benefits as well. With their special software algorithms, Walchem’s Wind (WebMaster Industrial) and WPH controllers are ideal for use in time-proportional control applications.

Two common methods

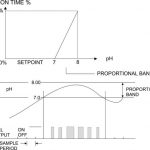

Proportional analogue is the most common control signal. This signal is often sent to a modulating control valve (positioner), a variable speed pump (centrifugal or diaphragm metering) or a variety of mechanical control options, for instance to control the speed of a belt drive. The premise is straightforward – the 4 to 20 mA signal value produces a direct, proportional output response (0 to 100 %) from the control device. With basic, proportional-only control, the signal value is calculated from a linear relationship based on the variance from the setpoint, with the maximum output occurring at a fixed maximum variance. One common example is pH control, where the output to an acid feed pump varies from 4 to 20 mA as the pH increases from 8 to 10. At 8 pH or less, 4 mA is sent to achieve 0 % pump output. As the pH rises to 10, the output increases linearly until finally at 10 pH or more, 20 mA is sent to the pump, corresponding to 100 % output.

In more sophisticated control scenarios, the algorithm to determine the output value may incorporate integral and possibly derivative calculations (PI or PID control), to enable a prediction based on the speed of the process response to the output. Even with PI or PID control, the actual output signal remains a 4 to 20 mA signal, resulting in a proportional 0 to 100 % response of the control device.

Proportional pulse control is used specifically to control solenoid driven metering pumps. A controller varies a pulse output based on the deviation from the setpoint, similar to proportional analogue control. Taking the same acid feed control example as above, the controller sends 0 pulses per minute to the metering pump at pH 8 or less, increasing the pulses/ minute output proportionally until at pH 10 or greater the maximum pulse output is reached. The metering pump strokes once for each pulse it receives, enabling the rise in pH to produce a corresponding increase in the metering pump’s delivery rate.

Benefits of time-proportional control

Time-proportional control has the advantage that it utilises a lower-cost on/off control device such as a solenoid valve or a fixed-output pump. A proportional response is achieved by proportioning the on and off times of this control device within a fixed time period (sample period). The off-time control portions provide additional benefits by enabling better mixing of the process or time for reactions to take place.

The parameters used to programme a time-proportional output include the sample period, setpoint, proportional band and control direction. The setpoint is the desired pH of the system while the control direction determines whether the output increases above this setpoint (often called the high setpoint) or below it (low setpoint).

The sample period should be set to approximately 1½ times the time it takes for the system to react to the chemical addition. This can be determined by adding chemicals manually and measuring how long it takes for the process to react. Setting too short a sample period will result in a second chemical dose being added before the first has even been detected and cause the setpoint to be exceeded. Setting too long a period will delay the next dose and could prevent the setpoint from being reached.

Finally, the proportional band is the deviation from the setpoint that results in 100 % on-time at the output. Returning to the acid feed pump example cited in connection with pH control, we could set a sample period of ten minutes, a high setpoint of 8.0 and a proportional band of 2 pH (from 8 to 10). At 8 pH or below, the output will be off for 100 % of the time. At 10 pH or above, the output will be on for 100 % of the next ten-minute sample period. At 9 pH, the output will be on for five minutes, then off for five minutes. The percentage of on-time during the ten-minute sample period increases proportionally as the process moves away from the setpoint. The actual on-time can be calculated by dividing the difference between the actual pH and the setpoint by the proportional band and then multiplying the result by the sample period. The off-time is the remainder of the sample period. In the example shown in Figure 2, the setpoint is 8.0 pH and the proportional band 2.0 pH. Note that when the pH rises above the setpoint, the control relay is on for a short period of time. If the pH increases, the control relay is on for longer. As soon as the chemical addition starts to affect the process pH and the pH is reduced, the control relay is on for a shorter period of time. If the pH drops below 8.0 (setpoint), the control relay is off all the time.

In addition to lower-cost control devices, there can also be other process benefits. Some plants utilise waste process streams as their neutralising chemicals (i.e. waste acid baths as acid reagent or waste cleaners – generally alkaline – as caustic reagents). Many of these streams are too dirty to be pumped using standard solenoid metering pumps. A solenoid or actuated ball or diaphragm valve on a gravity feed system can provide a lower-maintenance option.

Applications and limitations

Time-proportional control should not be used in once-through (on-the-fly) control processes, such as chemical injection into a pipe. These systems require feedback and prediction algorithms that are found in PID. Time-proportional control is ideal for recirculating processes or those with a built-in retention time (e.g. neutralisation tanks). A system with a retention time of ten minutes or longer is suitable. To determine the retention time of a system, simply divide the tank volume by the flow through the tank, i.e. a 600 gallon tank with flow in/out at 60 gpm equals a retention time of ten minutes.

cpp-net.com/0214401

Share: