New, innovative products and their efficient production processes usually come into being after long and cost-intensive testing procedures. Laboratory automation systems support employees with reliable information management, thus increasing their productivity, and therefore secure the company’s competitiveness and success. A qualified system also enables initial quantities of a material to be produced in such facilities even in a regulated environment.

Martina Walzer

Creating the most suitable production processes for products with improved usability features demands intelligent methods for process development. A host of tests with modified reaction parameters supply precisely the information required to decide on the optimal reaction conditions. The information they provide can be used to determine the environment that best combines maximum product output with minimum waste.

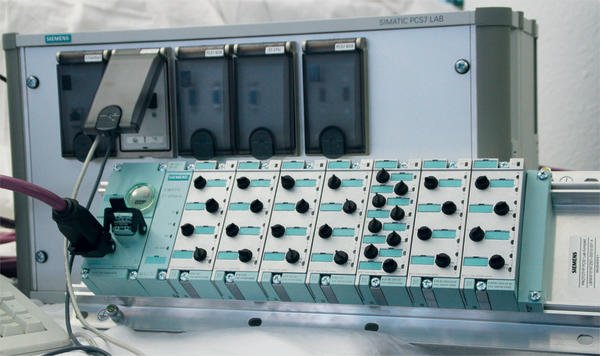

Intelligent information management, as well as maximum safety and reproducibility of the experiments, increases the quality and efficiency of the research work. To effectively support employees in research and process development, the Siemens Industry Automation Division offers the modular Simatic PCS7 Lab system. Based on the field-proven standard components of the scalable Simatic PCS7 process control system, this laboratory solution guarantees safety by means of seamless monitoring and alarm management in conjunction with continuous logging of events. Integrated and seamless acquisition, analysis and archiving of data play a decisive role. Simatic PCS7 Lab comprises a processing station and various input/output stations. Tailored to the special requirements of labs, its distributed design in a sturdy housing allows flexible use at changing locations.

The processing station is based on the PCS7 Box, a compact device that combines functionalities for automation, control & monitoring and engineering. The lab system works with the PCS7 standard system software, so that application scale-up becomes child’s play. An automation station ensures safe process control. The system is supplied pre-configured and the user can start recording measured values immediately. If necessary, the default parameters (for example, measuring range limits) can be adapted to specific measurements without difficulty.

The input/output station is based on the Simatic ET200M distributed I/O system and offers a pre-configured number of channels (analogue, binary) as well as serial interfaces for connecting lab scales, for instance. The individual channels are designed as plug-in connections. This significantly simplifies setting up the lab automation because the wiring for the devices no longer needs to be carried out by an electrician. I/O modules in the ET200Pro series can also be used in addition to the input/output station mentioned above. Thanks to their IP67 protection class, they are suitable for direct installation in the lab’s fume hoods and therefore require much less space.

The system can be operated as a stand-alone solution or integrated in the automation setup. The labs can be easily embedded in the plant network if desired, facilitating efficient information exchange. A wide range of components are available for the control system to automate the most diverse plant types and sizes. Scaling up applications to the size of pilot plants, and finally to production, is a simple matter.

Safeguarding knowledge

Efficient cooperation between individual scientists and process engineers plays an important role in research and process development. Electronic lab notebooks (ELN) offer strong support for this kind of collaboration. Complete and unbroken documentation of experiments – successful or otherwise – helps avoid repeat trials and thus leads to faster results. Significant advantages are achieved by creating and managing all documents and associated experimental data in electronic form.

- Paper-bound records are replaced, avoiding time-consuming searching through piles of notes, while forgery-proof storage with electronic signatures protects intellectual property.

- Research results are moreover available across different sites within a company. Redundant trials due to missing information are eliminated – a considerable cost advantage.

- Central storage of experimental data guarantees its subsequent traceability; archiving this data with a time stamp is important for patent grants because unbroken documentation is a must.

The ELN functionality is a central component of the Simatic IT R&D Suite software, which is an option for Simatic PCS7 Lab. It effectively supports system-wide management of experimental data and planning trials. The process values can be transferred to the test log on request and then used for other processing and analysis steps. Transfer errors are avoided, leading to a significant improvement in data quality.

Hall 9, Booth A72

cpp 461

Weitere technische Informationen zu Simatic PCS7 Lab

Laborautomation bei Siemens

Analytica 2008 – Leitmesse für Instrumentelle Analytik, Labortechnik und Biotechnologie/Life Science

Share: