Those conducting gas analyses at changing locations previously had a heavy burden to carry. The gas conditioning system alone, stowed away in a bulky case, often weighed almost 20 kg. The PCS Base system by Bühler Technologies weighs less than half that figure. Designed to be carried in a convenient shoulder bag, it can be lifted easily for comparison or sample measurements. Coolers, filters and pumps as well as optional moisture detectors and flow meters set the stage for reliable analysis values.

Sample gas conditioning using a 7 kg lightweight system

Taking emissions lightly

Those conducting gas analyses at changing locations previously had a heavy burden to carry. The gas conditioning system alone, stowed away in a bulky case, often weighed almost 20 kg. The PCS Base system by Bühler Technologies weighs less than half that figure. Designed to be carried in a convenient shoulder bag, it can be lifted easily for comparison or sample measurements. Coolers, filters and pumps as well as optional moisture detectors and flow meters set the stage for reliable analysis values.

Service technicians are often not to be envied. By definition, they travel a lot and are obliged to cope with any conditions wherever the client happens to be located. For those charged with measuring emissions in so-called recurring inspections, this means taking the gas conditioning system, including the sample gas probe and analyser, to the jobsite – which is typically a stack. With their typical weight of nearly 20 kg, conventional portable gas conditioning systems, stowed away inside a case with a handle, make this task anything but easy. Safety is also an issue since the user only has one free hand.

The development engineers at Bühler Technologies, the specialists in analytical technology, have now come up with a radical response. The predecessor TGAK solution still weighed 18 kg. Although (in German) its name was an acronym for portable gas analysis inside a case, the portability of this gas conditioning system was in actual fact limited. The new system – PCS Base – weighs in at a mere 6.8 kg. Service technicians can easily strap it on their back because the PCS Base comes inside an ultra-lightweight bag which, like a camera case, also offers plenty of room for accessories such as the Baseline sample probe.

Focusing on the essentials

The Baseline and the PCS Base match perfectly. Together they make a solution which is ideal both for servicing and for comparative and sample measurements. Oliver Fries, Head of Gas Analysis Sales for EMEA & South America at Bühler Technologies, reports: “Numerous customers simply want to carry out regular checks of oxygen or carbon monoxide levels, for instance. That’s where our simplified combination of the Baseline sample gas probe and the PCS Base gas conditioning system are just right.” Bühler Technologies first presented the prototype of this lightweight at Achema – and impressed customers straight away. Several visitors to the exhibition promptly requested a quotation. Fries admits that “this solution is very well suited for sample measurements. However, anyone who needs measurements to control a process or verify measured values for authorities should resort to more sophisticated technology such as the Smartline with PCS Smart.”

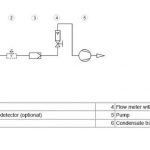

The light weight of the PCS Base stems from focusing on the essentials. The standard version consists of a Peltier cooler with a condensate trap, filter and gas pump. A flow meter and moisture detector can be added if neces-sary. However, the flow meter is only necessary if the analyser itself does not have one.

The moisture detector protects the analyser against the ingress of moisture. It therefore communicates with the sample gas pump, which is switched off in case of gas cooler overload. “I would almost always choose the moisture detector”, Fries advises, “because it protects the analyser – a delicate and expen-sive measuring instrument – from moisture, which is liable to lead to damage or impaired functionality.” A good deal of money can be saved on cleaning and maintenance in this way.

Two cooling options

The Bühler engineers selected the recently released TC-Mini as the cooler. Developed specifically for portable gas conditioning systems, it provides two possible options: a fixed output dew point of 3, 5, 10 or 15 °C or alternatively cooling based on DeltaT control. The system normally cools the system to the 5 °C preset. An output dew point of 5 °C means 0.8 % residual moisture, in other words approximately 8000 ppm – an established stand-ard in emissions measurement. Fries: “This is a defined state which always returns comparable values. The ambient temperature does not usually fall below this value during the measurements, so that the system is effectively protected from moisture loss.”

The TC-Mini cooler, however, also features DeltaT control, which is particularly beneficial when trying to determine non-water-soluble gases. It ensures that the gas temperature always remains a specific value below ambient. Due to the defined temperature difference, the residual moisture in the cooled gas no longer condensates inside the analysis system. The output dew point fluctuates in this application along with the ambient temperature. The carbon monoxide or oxygen content, however, can be determined fairly accurately. The advantage here is that if the system only cools to 35 °C instead of 5 °C at an ambient temperature of 50 °C, the cooling performance is improved while condensation in the analyser is reliably prevented.

It is important to keep in mind with this application that the ambient temperature must always be higher than the output dew point setting, or moisture will condense in the lines behind the cooler.

The PCS Base is not only extremely simple to use with the bag open; it is also easy to maintain. The filter is accessible from the front and can be replaced when dirty. If the condensate trap is full, the condensate can be drained via the compression valve, then collected in the container which is included with the system and disposed of properly. The pump and cooler are durable and essentially maintenance-free. All the necessary maintenance steps are clearly illustrated in the manual with a readily understandable description.

Hands-free servicing

Following the encouraging feedback at Achema, which only resulted in the modification of a few small details, the PCS Base went into series production in October 2015. Fries is excited at the success so far: “Now we also have an optimal solution for users seeking a lightweight, quick and easy-to-operate gas sampling and conditioning system.” Service technicians who in future have their hands free when climbing the next stack will be grateful for it. Once at the top, the system is ready to use after only ten to fifteen minutes, depending on the ambient temperature.

www.cpp-net.com search: cpp0316bühler

Share: