The Norwegian company Gassecure has combined a gas detector featuring IR absorption spectrometer technology with wireless communication. The GS01 is used to detect the presence of hydrocarbon gases and warn operators of a fire or explosion risk. Its ultra-low power design and small integrated battery pack enable up to two years of continuous operation.

Wireless infrared gas detector

Rapid warning of fire or explosion risks

The Norwegian company Gassecure has combined a gas detector featuring IR absorption spectrometer technology with wireless communication. The GS01 is used to detect the presence of hydrocarbon gases and warn operators of a fire or explosion risk. Its ultra-low power design and small integrated battery pack enable up to two years of continuous operation.

Engineer and Gassecure founder Knud Sandven first recognised the potential of wireless technology back in 2004, when he developed a vibration sensor for small engines that reliably transmitted the data it gathered by wireless. Wireless technology for rugged and demanding industrial use was still in its infancy and only very few applications were actually on the market. For quite a while, wireless was considered to be instable and prone to malfunctions. At the same time, no one had any practical knowledge of how a 2.4 GHz radio link would behave in a jungle of rigs, cranes, cables and oil tanks, or whether existing electrical and electronic equipment would interfere with the wireless signal – or vice versa. Today, these reservations and doubts have been allayed. In practice, wireless is just as reliable as cables. This is ensured by detailed planning (for distances up to 400 m) and sophisticated transmission protocols that facilitate secure communication. The wireless sensor is in no way inferior to existing cable-dependent solutions. It also has an operational lifecycle of around two years – without maintenance, external power supplies or the need for on-site recalibration. Hundreds of wireless detector units are able to function perfectly in a collision-free integrated network.

Companies like Statoil and Conoco Phillips sponsored the development and stringent testing of its hardware and software components. 2012 saw the delivery of the first unit to Statoil, the Norwegian oil and gas corporation. Since then, only a negligible proportion of the thousand units marketed so far have either malfunctioned or failed (1 %). The Norwegian enterprise has been “A Dräger Company” since 2015. In the meantime, the GS01 is also produced in a version with an extended antenna. This allows the transmitter to be installed at ground level, which would otherwise be an unfavourable location for data transmission if the unit had a fixed antenna. The new antenna position is much better suited for wireless communication. Norway is not only home to the company’s R&D, but also to production and quality assurance.

Robust gas sensor

Precision, a rugged design and reliability are requirements ably fulfilled by the Gassecure wireless gas detector. Its integrated battery power source guarantees continuous and reliable operation for at least two years and also enables data gathered on site to be transmitted to the control room in 5 s or less. What it measures is the concentration of gaseous hydrocarbons in the ambient air. Methane, in particular, which is a major component of natural gas, is a highly explosive mixture in the presence of air at concentrations of more than 4.4 % (lower explosive limit). Virtually continuous monitoring is essential. The detector sensor responds reliably to the presence of gaseous hydrocarbons (qualitative analysis) and prevents false alarms by identifying their concentration (quantitative analysis).

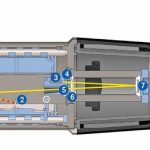

The GS01 measures the concentration of gaseous hydrocarbons in the sampled air through their absorption of light in the infrared spectrum. The infrared light is emitted by a small lamp with an exceptionally long service life. It passes through a system of lenses to a mirror and is reflected back along its path. The beam therefore travels a distance of 2 x 5 cm in a measuring chamber that is open to the surrounding air. All electronic components of the unit are installed in a gas-tight steel housing filled with inert nitrogen at slight overpressure. The beam is deflected from this measuring chamber through a window and aperture into the housing where the analysis takes place. It then falls on the analytical core of the detector (also known as MEMS or micro-electro-mechanical system), which carries out a spectroscopic analysis of the incoming light.

Two sub-cycles per measuring cycle

Gaseous hydrocarbons absorb light in a waveband of approximately 3.3 µm, while the frequencies above and below this value are not subject to attenuation. The MEMS functions in a similar way to a prism. It splits the incident light and reflects the various spectral components in different directions. The system can be configured to produce the same effect as rotating a prism. This ensures that only certain wavelengths fall on the photodetector. Each measuring cycle consists of two sub-cycles, where the first cycle determines the intensity of the light in a central band with the wavelength 3.3 µm and the second measures the intensity in the neighbouring bands at 3.0 and 3.6 µm. If gaseous hydrocarbons are present in the sampled air, they only absorb light in the central 3.3 μm waveband. Due to this absorption effect, the energy value registered by the photo detector for this wavelength (3.3 μm) is lower in comparison with the values for the shorter (3.0 μm) and longer (3.6 μm) wavelengths. In fact, the lower this value, the higher the concentration of gaseous hydrocarbons. The hydrocarbon concentration is calculated from the difference between the measured values from the first and second sub-cycles. If they differ, gaseous hydrocarbons are present in the sampled air. Every ten seconds, the data gathered in this way is sent to the control room for analysis over a secure 2.4 GHz wireless link with 10 mW RF power output as per IEEE 802.15.4. If the concentration rises above a defined threshold value, the data transmission rate is usually reduced to intervals of 2 s.

www.cpp-net.com search: cpp0316dräger

Nils Schiffhauer

Nils Schiffhauer

Journalist

Share: