Ammonia is widely used in many processes in the chemical industry. Amongst other things, it is the raw material for the production of fertilisers. It is also employed industrially as a cleaning agent, disinfectant and refrigerant. Ammonia is commonly stored as anhydrous ammonia. Precise level measurement in those pressurised vessels is difficult, because Ammonia has the tend-ency to change between the liquid and vapour states.

The author: Sarah Parker Emerson Process Management

Ammonia is usually stored as a liquid in pressurised vessels and can be a very difficult compound to measure reliably due to its tendency to change between the liquid and vapour states as the pressure and temperature varies. In addition, the surface of the fluid tends to boil as it moves between states and the heavy vapours can affect measurement accuracy. Ammonia is hazardous and an irritant. It will also diffuse through many elastomers and this needs to be taken into account when selecting measurement technologies and devices.

Boiling at the surface has the disadvantage that displacer based level devices often give inconsistent results that do not match the actual level. Moreover, contact with caustic ammonia means that frequent maintenance is required to replace components. Differential pressure (DP) level sensors struggle with the challenges of measuring ammonia owing to the changing density of both the liquid and the vapour space. Radar based sensors, on the other hand, are ideal for this purpose. The choice of non-contacting or guided wave technologies depends on the context. Low-frequency radar devices, for example, are less prone to attenuation and better suited to many ammonia applications. There are also different methods of propagation. While some designs project the radar signal down through the atmosphere to the surface of the liquid, others use a probe to guide it.

Whichever technology is chosen, ammonia is a hazardous substance and it is important to protect operators from contact with its vapours. Bearing this in mind, some radar devices are designed so that when installed, they can be easily isolated for maintenance – minimising the risk to the operator. Transmitter heads can thus be serviced without breaching the tank atmosphere, eliminating any problems caused by the need to open the tank.

Guided wave or non-contacting?

Radar level sensors are generally based on either guided wave or non-contacting technologies. In a guided wave radar (GWR) installation, the GWR is mounted on top of the tank or chamber containing the ammonia with the probe extended to the full depth of the vessel. A low-energy pulse of microwaves is sent down the probe; when it reaches the ammonia surface, a reflection is sent back to the transmitter. The transmitter measures the time taken for the pulse to reach the ammonia surface and be reflected back while an on-board microprocessor accurately calculates the distance to the surface using ‘time-of-flight’ principles.

As GWR is not density-dependent and is unaffected by high turbulence or vibrations, its measurement accuracy and reliability in ammonia applications are good. Since there are no moving parts to stick or wear, maintenance costs are minimised and the problem of false readings leading to hazardous situations is avoided. Guided wave radar is suited for measuring both liquid anhydrous ammonia and aqueous ammonia.

Non-contacting radar devices provide a top-down, direct measurement of the distance to the surface of the ammonia. They send a signal through the vapour space that bounces off the surface and returns to the gauge. No compensation is necessary if the density, dielectric or conductivity of the fluid changes. As it is non-contacting, its susceptibility to corrosion is lim-ited. Both guided wave and non-contacting radar are suitable for measuring liquid aqueous ammonia (ammonium hydroxide or ammonium hydrate). These same technologies will also work with many other liquid ammonia solutions.

However, the tanks used to store the ammonia sometimes require isolation valves. It is therefore not possible to use guided wave radar with valves unless a bypass chamber is installed. If the radar is mounted directly on the vessel and a valve is required, this valve must be a full-port type so that the inside of the nozzle is smooth. A non-contacting radar transmitter – such as the Rosemount 5402 with a process seal antenna – is preferred in conjunction with valves because it uses a higher frequency (24 GHz) which allows better signal propagation down the nozzle. The process seal antenna has a dish made of PTFE which seals off the cone-shaped antenna from the tank atmosphere. This means that only corrosion-resistant, non-metallic materials are exposed to the atmosphere inside the vessel.

Level measurement in anhydrous NH3

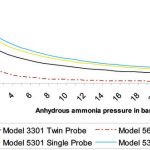

Liquid anhydrous ammonia is difficult to measure because it produces heavy vapours that attenuate radar signals. As the storage pressure increases, the density of these vapours also rises. Heavier vapours result in more signal attenuation. For this reason, the overall range capability of the radar decreases as the pressure increases. This effect is more pronounced with higher-frequency units. A stilling well can help to increase the range capability.

Guided wave radar operates with a low-frequency pulse. Since lower-frequency radar signals are less attenuated in heavy vapour, guided wave radar is a better option than non-contacting technology in high-pressure installations.

Turbulence from product boiling may affect the radar reflection during operation. If guided wave radar is used, this effect is much less. A stilling well will strengthen the signal with both GWR and non-contacting radar.

Proven results

Kerteh Terminals in Malaysia was using a displacer to measure the level of anhydrous ammonia in a tank. Displacer technology is commonly employed for low-temperature applications down to -33 °C. The displacer technology presented the customer with many problems owing to the difficulty of carrying out measurements. Firstly, the readings were inconsistent and did not match the actual level. Secondly, the density of ammonia often changes as it moves between vapour and liquid phases, and it can also vary in response to moderate pressure or level changes. Finally, frequent repairs were necessary and parts regularly had to be replaced on the existing displacer system.

Due to the small span, heavy vapours and changing density, differential pressure level and non-contacting radar technologies are not good choices for anhydrous ammonia applications. The customer installed a Rosemount guided wave radar and found that it met all expectations. With its low-frequency signal, the Rosemount GWR is unaffected by the heavy vapours that commonly attenuate higher-frequency signals. Kerteh Terminals specified the Rosemount GWR with a coaxial probe, because this provides a strong, uninterrupted signal that further enhances the level signal in this highly condensing environment. In addition, the Rosemount GWR has no moving parts, making it virtually maintenance-free.

cpp-net.com/0112416

Share: