High-temperature humidity measurement is problematic in practice because, when the temperature rises above 100 °C, the maximum relative humidity level drops drastically. The boiling point of water limits the process humidity to a dewpoint temperature of 100 °C Td. As the difference between the process temperature T and the process dewpoint Td increases, the accuracy of humidity measurement typically decreases. To achieve better values at high temperatures, Vaisala has developed the Drycap technology.

Jan Grönblad

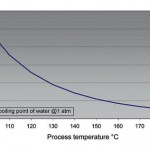

Direct humidity measurement in high-temperature applications can be a challenging task. When the process temperature rises above 100 °C (212°F), the relative accuracy of a traditional humidity instrument is acceptable providing the amount of moisture in the air is high. However, as the humidity level drops, the measurement accuracy suffers. In high-temperature applications the humidity is typically low due to the fact that, as the temperature increases, the relative humidity level decreases rapidly. Figure 1 illustrates the maximum relative humidity in the temperature range from 90 to 200 °C (194 to 392°F). The humidity value is always below the blue saturation curve, which starts to fall fast when the process temperature exceeds the boiling point of water.

A sampling system is one way to get round the accuracy problem resulting from high temperature. Sampling the process air into cooler conditions outside the process keeps the humidity reading at a level where the accuracy is good with traditional technologies. This works in very dry applications, where the process humidity does not condense in the sampling system, for example in heat treatment systems where a dry shield gas is used. On the other hand, many typical drying applications (e.g. foodstuffs or pharmaceuticals) use heated air with a relatively high humidity and no shield gas.

The drying process attempts to remove the moisture from the dried product as effectively as possible. The dewpoint temperature (humidity) of the process is tempo-rarily – for at least part of the drying cycle, if not throughout the whole of it – higher than the outside temperature. This results in saturation in the sampling system. Direct measurement should therefore always be preferred where possible to avoid the risk of the sampling system being filled with water.

Direct installation

Measuring the humidity of exhaust air in a drying process is typically a very good indication of the material moisture of the dried product and, when suitable, a very reliable online measurement. The key issue in drying applications is to determine whether the dried product is dry enough. At the same time, the product should not be over-dried, in order to achieve the optimal product composition and minimise energy consumption. The more accurate the measurement, the narrower the window for the end product’s moisture content. If accuracy higher than traditional humidity measurement precision with ±1 or 2 % RH is required, and if a rugged and durably stable measurement is preferred, Vaisala’s latest Drycap dewpoint transmitters are the right solution.

The Drycap DMT345 and DMT346 transmitters (Figure 2) offer high measurement performance when directly installed in hot and dry processes, thanks to the updated auto-calibration function that now also operates at high temperatures. The process temperature range for direct installation can be as high as +350 °C (660 °F). Both models incorporate the auto-calibration method that has been used in low-humidity applications at low temperatures for years and is held in high esteem by customers. The patented technology offers very good accuracy and simultaneously maintains excellent long-term stability. For the user, this means not only reliable measurement values but also efficient process control with low maintenance costs.

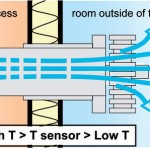

The difference between the two dewpoint transmitter models is the passive cooling method (Figure 3), which enables the DMT346 to be installed directly at temperatures up to +350 °C (660 °F). Regardless of such extreme temperatures, passive cooling keeps the heat within a range that will not burn the sensor. Passive cooling has the advantage of not requiring any external power to generate the cold, and the sensor works even in power loss situations. The mechanics conduct heat from the sensor to the outside of the hot process. In addition to protecting the sensor against extreme temperatures, the measurement accuracy can be improved if the temperature around the sensor is lower than in the actual process. The reason for this is that when the temperature drops, the humidity the sensor detects increases to a more sensitive range. Together with the auto-calibration function, this allows measurements with very good accuracy over a wide range.

To avoid getting wet in situations where the process humidity is high, the sensor also has an integrated heater that automatically switches on when a risk of saturation is present. This can happen, for example, during process changes or at the start of the drying phase. When the conditions in the process return to normal, the heater is automatically switched off. The visibility of this operation is minimised, making the instrument fully automatic and easy to operate.

Many instruments have specifications for humidity measurement at high temperatures. In applications where humidity is low and temperature is high, the Drycap DMT345 and DMT346 transmitters provide the best accuracy. If the temperature is lower and the humidity likewise low, Drycap DMT340 – Vaisala’s basic series of dewpoint and temperature transmitters – is recommended. If there is no need to measure accurately at low humidity, the Humicap HMT330 humidity and temperature transmitter is the ideal choice.

cpp 451

Vaisala’s product range

Share: