Changing environmental awareness, supported by TA Luft 2 (German Technical Instructions on Air Quality Control), has led even higher significance to be attached to the sealing of control valves. The ideal stem seal needs to meet TA Luft regulations without this strict tightness standard resulting in additional expenditure, higher actuator forces or friction forces on the packing leading to poorer controllability.

Plant engineers are faced with manifold situations where components have to be sealed against leaking products or the ingress of dirt. These seals are divided into static seals (e.g. for flange connections or covers) and dynamic seals (for applications involving a relative movement of the components to be sealed, e.g. control valve stems). Compliance with TA Luft 2, which has been effective since the year 2000, is stipulated in such cases. However, the required high degree of tightness not only interferes with the valve’s performance due to the design-related friction properties (slip-stick effect), it also results in higher actuator forces or an increased overall height of the valve.

In order to meet TA Luft requirements, the majority of stroke valves use metal or plastic bellows. On the one hand, these bellows have far lower leakage values than stipulated by TA Luft but on the other, they are not without drawbacks. If austenitic stainless steel is used as the bellows material, only minimal expansion and compression strain is permissible in order not to shorten the lifespan of the bellows. The overall height of the complete control valve can thus exceed that of a valve with a gland by as much as 40 %. Furthermore, the bellows causes significant additional forces at higher pressure ratings, which have to be provided by the actuator. Particularly when handling strong acids, its resistance is limited. The additional cost for the complex design of the bellows stem seal also has to be considered.

If a highly acid-proof PTFE bellows material is chosen, the temperature and pressure ranges are severely restricted. However, as a result of the material’s elastic force, there is almost no noticeable increase in the actuation forces and the bellows can be comparatively short, so that the overall length of the valve only exceeds the gland design by approximately 20 %. Once again, however, the design entails substantial extra costs.

Permanent sealing

When assessing the technical quality of components with relative movements, it needs to be remembered that three different types of leak can occur, namely between the stem and the sealing element, between the bonnet and the packing element and in the form of diffusion through single or multiple packing elements. The ideal packing gland should meet TA Luft regulations without the considerably higher tightness standard of the valve resulting in a sizable increase in the friction forces acting on the packing and without any impairment to control quality. To achieve this, compound materials are chosen for the majority of applications, mainly PTFE in combination with other materials such as pure graphite.

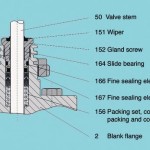

The Arca Ecotrol control valve takes special account of TA Luft regulations. Permanent dynamic sealing between the stem and the spring-loaded packing set is provided by a valve stem with superfinishing, four chevron-type packings and an additional elastomer sealing element with four lips. All dynamic sealing elements are designed with increased system pressure onto the sealing face (seal effect).

Permanent and reliable dynamic sealing necessitates a suitably finished surface of the face to be sealed (valve stem). For this reason, the stem is provided with a plastic-coated slide bearing, which prevents metal contact with the initial load element and/or the bonnet. Moreover, the packing elements and the fine sealing element are positioned in such a way that no damage can occur to the area to be sealed during the valve stroke, even if the valve stem is dam-aged in the exposed area as a result of improper handling.

In order to avoid leaks in the static seal region between the sealing element and the casing, the packing chamber is likewise superfinished and additionally provided with a static sealing element (O-ring). To rule out the ingress of dirt, the stem seal also has a wiper element. The static sealing element moreover helps reduce leakage due to diffusion. Extensive tests have been carried out in connection with the TA Luft certification (based on VDE 2440 and EN ISO 15848).

Hermetic separation

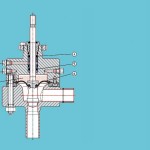

The need for fail-safe, leak-free and hermetically tight stem seals has resulted in a series of new developments. The hydrau- lically supported Optiseal double-dia-phragm seal represents a very interesting alternative to traditional bellows types. It is designed with redundant sealing between the fluid chamber and the environment. A pre-formed elastic diaphragm serves as the hermetic sealing element (primary seal) to the product. The seal from the hydraulic chamber to the outside in the valve stem area is ensured by means of special, permanent primary and secondary sealing elements. Each of these barriers works independently of the other. The unique feature of this design is the hydraulic support of the ring diaphragm, which reduces the load on the latter to a minimum, even at working pressures of up to 320 bar. The hydraulic fluid is incompressible and compatible with the product. A non-hazardous fluid can also be supplied on request. During the reciprocating action of the stem when moving from the closed to the open valve position, the variation in the actuation fluid chamber volume is compensated by the change in the diaphragm shape from the original pre-formed concave to a convex profile.

Despite being rated for a maximum pressure of 320 bar and operating temperatures up to 200 °C, the Optiseal is extremely compact and intended for one million full-stroke cycles. The redundant double-diaphragm design allows predictive maintenance. The complementary diaphragm, in other words the diaphragm towards the hydraulic fluid, is provided with star-shaped and ring-shaped channels that end in a centre passage. These channels are innately pressureless. If one of the dia-phragms fails, either product or actuation fluid will enter the leakage channels. The diaphragm failure results in a build-up of pressure that can reach the working pressure, so that the product or actuation fluid is detected by the condition monitoring system. In any case, functional efficiency is maintained by the remaining diaphragm. Even aseptic conditions are not affected.

Depending on the actual application, Optiseal ring diaphragms can be made of common elastomer materials and/or PTFE. They are suitable for all applications where hermetic separation of the process fluid is imperative. The stem sealing system is moreover ideal whenever highly abrasive products, such as scouring media, prohibit the use of sliding seals. It was particularly designed for sealing control valves and exhibits remarkable potential:

- Absolute tightness

- High operating reliability, even in the event of a fault

- Long lifespan, leading to reduced maintenance and higher availability

- No dead space, no stem bushing and no gaps

- Same efficiency under pressure and vac-uum

- Simple, effective cleaning (SIP and CIP capability)

Last but not least, the capital investment is comparatively small owing to the compact design and the fact that costly monitoring systems can be dispensed with.

Online info www.cpp-net.com/2309403

Share: