The storage of hazardous materials has been an issue for decades and is specified in various legal texts such as the German Occupational Safety Regulations (BetrSichV) or the Technical Regulations for Flammable Liquids (TRbF). Clearly formulated definitions exist for active and passive storage. However, the solutions implemented in practice often deviate from legal requirements. Standardised concepts are difficult to find, especially for active storage of smaller quantities in the working area, e.g. a 200 l drum of flammable liquid.

Christian Völk

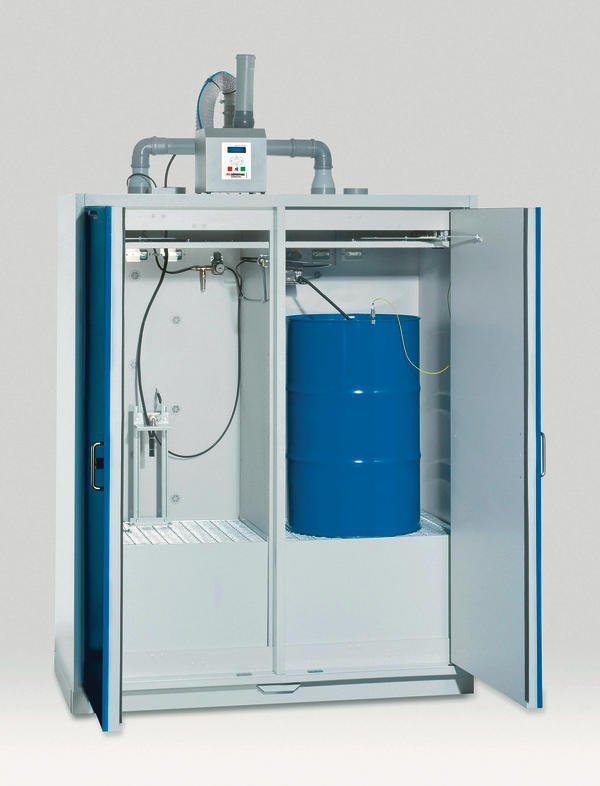

There are safety cabinets on the market for passive storage of 200 l drums according to TRbF 20, Annex L or EN 14470–1. However, it is extremely rare that a 200 l drum of flammable liquid needs to be stored sealed (= passively) at the workplace. Active storage tends to be far more common in practice. Active storage is the storage of flam-mable liquids in mobile containers, which are used at the storage location as stationary discharge or collection containers or opened for other purposes. Which method is best suited, therefore, if active storage is required? Düperthal decided to tackle this question and, in collaboration with experts at TÜV Süd, developed a series of products to solve these problems. In the first step, the focus was on a safety cabinet according to EN 14470–1, which had already been approved for passive storage of a 200 l drum. Yet how can a passive safety cabinet be turned into a cabinet that is also approved for active storage?

Safety without compromises

One important aspect of active storage is continuous earthing in accordance with the TRbF 30 requirements for filling stations and the guidelines of the employer’s liability insurance association (BGR 132: “Avoidance of ignition hazards“). This requirement is met by Düperthal’s XL cabinets in that all metal components inside them, such as the collection trays and grating, are conductively connected to one another. In addition, the cabinets are equipped with two earthing terminals, one each for the drum and the drum pump. There are prepared earthing connections on the top of the cabinet which enable the user to earth the system and thus prevent static.

According to TRbF 20, Annex L, safety cabinets for passive storage do not necessarily have to be connected to the ventilation. When it comes to active storage, critical Ex zones (hazardous areas) exist due to the open container. The drum cabinet must consequently be ventilated with at least ten air changes per hour. The ventilation must moreover be activated on each cabinet level, which is achieved in a drum cabinet by means of supply and exhaust air roses. It is also necessary to monitor the ventilation function and to comply with the legal requirements for fans. The XL cabinet therefore offers a pluggable fan unit with integrated exhaust monitoring that conforms to ATEX.

The doors of the safety cabinets are self-closing in the event of a fire. For active storage with drum pumps, however, this means that the media and energy lines cannot simply be laid through the open doors. A pipe penetration for stainless steel pipes provides the ideal answer. Up to such pipes with a maximum diameter of 20 mm, or optionally one pipe with a 28 mm diameter, can be laid through this penetration so that they exit from the side panel or the top of the cabinet. The pipe penetration has been successfully tested in a fire chamber with the drum cabinet by an independent materials testing institute. The safety cabinet is classified as Type 90 (= fire resistant for at least 90 minutes). This represents an optimum solution for connecting an explosion-proof compressed-air drum pump inside the cabinet.

The concept of the active drum cabinet is meanwhile a product in a complete cabinet line known as Flow line. All Flow line safety cabinets are approved for active storage of flammable liquids. In addition to the drum cabinet, they also include the XXL drum station. With its standard fittings, the filling and transfer station is perfect for safe storage and transfer from 200 l drums containing flammable or water-polluting liquids. The drum station consists of two Type 90 classified safety cabinets, including a self-closing tap with an extractor, an explosion-proof compressed air pump with automatic emergency stop in the event of a fire, a collection capacity of 2 x 220 l and an exhaust monitoring unit with a fan conforming to ATEX. The canister cabinet allows optimum storage of canisters according to ADR/RID and safe filling of hazardous materials into smaller containers, including an exhaust monitoring unit with fan conforming to ATEX. Düperthal’s standards include testing of all safety products by an accredited institute such as TÜV Süd as well as confirmation of these tests in the form of the GS mark. Each customer receives a GS certificate and decla-ration of conformity according to DIN EN 14470–1 and DIN EN 14727 together with the operating instructions.

Düperthal Sicherheitstechnik GmbH & Co. KG

Share: