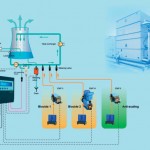

With its two devices Multronic and CoolProtect and the Elados EMP metering pump program, Ecolab offers users a cost-effective, safe and precise metering, measuring and control system for all cooling water treatment processes. This prefabricated system considerably simplifies configuring, installation, commissioning and plant servicing.

Massoud Nahidino

Heated cooling water which occurs in large quantities in power stations or industrial processes is usually cooled back down in cooling towers. Special attention needs to be paid to the use of cooling water, energy consumption and system protection for economical and ecological reasons. The cooling water itself can cause particular problems here. Conditional evaporation of the water leads to thickening of salts and minerals, e.g. in the form of sludge in the cooling water circuit. Ingredients such as lime in the water can also form deposits. Deposits and precipitations result in poor heat transfer and possibly blockage of the cooling ducts. Another challenge is presented by the biological and microbiolo-gical growth of bacteria, legionella and mould, creating a slime in the water which can likewise obstruct the cooling ducts. In addition, all legionella are considered potentially human pathogenic. If sulphur dioxide (SO2) gets into the cooling tower with air, this is also problematic. The SO2 is completely oxidised to SO3 by dissolved oxygen. The sulphuric acid subsequently formed with the cooling water leads to a drop in pH. As a result of these three processes, there is increased corrosion, entailing a risk of malfunctions in the operating process and even defective lines due to the formation of rust. Operation without cooling water treatment may save money initially but becomes very expensive later when the cooling tower is inspected and many of the components have to be renewed. In addition, energy costs can be much higher because of the diminished efficiency of the cooling system. However, these problems can be easily solved with Multronic and CoolProtect, the two metering, measuring and control units from Ecolab Engineering’s Lang Industrietechnik Division. The modular design of the devices facilitates a complete solution that is suitable for almost all cooling water and air washing systems.

Bleeding and biocide metering

The Multronic and CoolProtect continuously monitor conductivity in the cooling water and thus the salt content. The cooling water is desludged into the sewer system when the upper limit value is exceeded. At the same time the level control in the cooling system feeds in fresh water, which dilutes the cooling water and reduces the conductivity. Desludging ends when the conductivity drops below a preset lower limit value. The bleed valve with an electric motor in the normally open version offers additional safety. It prevents uncontrolled bleeding and therefore no-load operation of the cooling tower in the event of a power failure. This process, based on quality-dependent bleeding, offers significant advantages over the proportional principle.

High temperatures and high mineral concentrations favour the formation of microbiological cultures in the cooling water. It is necessary to meter a biocide into this water at regular intervals to protect the plant and rule out a health hazard to humans. When the Multronic and CoolProtect systems are combined with the EMP metering pump series, it is possible to trigger timer-controlled biocide metering. The length of the metering and product exposure times is selectable. Bleeding is always disabled during metering and exposure. The current operating status is shown in plain text. Pre-bleeding can also be activated. This means that if biocide metering is triggered by the timer and the conductivity value is simultaneously higher than the lower bleeding threshold, forced bleeding takes place prior to metering biocide. A se-cond biocide metering cycle provides additional protection against the formation of microbiological resistance. In order to stabilise the pH of the cooling water, monitoring with pH control is often inevitable. The type of cooling tower and the quality and hardness of the water play an important role here. The Multronic has a pH monitor with a separate control function. In combination with the EMP metering pump series, it permits automatic neutralisation or pH stabilisation of the cooling water. Metering of corrosion protection agents is controlled proportionally to the fresh water supply. The signals are passed on directly to the metering pump for this purpose by the water meter. In order to counteract contamination by germs in cooling circuits that are temporarily shut down, communication with the cooling water system’s control unit is possible as an option. This preselectable control function automatically activates the circulating pump of the water circuit when the cooling tower is shut down and triggers biocide metering after an adjustable circulation time.

Depending on requirements, a customised solution can be put together for different cooling tower systems by combining various Multronic/Coolprotect components without the need for complex configuration. The Coolprotect system offers many advantages for simple, effective cooling water treatment. If metering of two different biocides or additional monitoring and control of the pH level is required, the Multronic’s bleeding variant provides an optimum solution.

cpp 401

Overview of functions

- Conductivity-controlled bleeding regulation with inductive measuring cell

- Timer-controlled biocide metering and circulation control, also with surge metering function

- Week timer with real-time clock; two different metering times can be set per day

- Biocide metering can also be triggered in a water circuit that has been shut down

- Optional second biocide metering cycle to prevent the formation of microbiological resistance

- Settable disabling of biocide metering and bleeding (including pre-bleeding)

- Corrosion protection by proportional metering with contact water meter

- Optional pH monitoring and control with the Multronic

- Integrated acoustic alarm signal

- Simple, menu-guided operation in plain text

- Fast configuration, installation and commissioning

More about Multronic

Coolprotect at a glance

Share: