Energy-saving projects offer multiple opportunities for drive manufacturers to generate significant economies; at the same time, there are many potential sources of error that can compromise their success. The examples described here only illustrate a few of these pitfalls. However, they make it clear that to ensure effective measures, users must take account of each system’s basic conditions and constraints.

The author: Michael Burghardt Product Manager, Danfoss, VLT Drives

The price of energy has risen by approximately 12 % per year on average over the last decade, putting this cost factor on a par with personnel costs, which it is set to overtake in 2015, if the trend continues. Energy consumption is consequently of strategic importance for companies with particularly energy-hungry production processes. Depending on their objectives, duration and returns, energy saving projects can have a major influence on a company’s overall balance sheet and thus on its financial success. An energy-saving of between 15 and 25 % can make a huge difference to the profit and loss account.

Yet time and time again, energy optimisation measures for drives fail to achieve the desired results. There are several possible reasons for this, mostly related to incorrect analyses of the initial situation. One simple solution would be to fit all motors in the system with frequency converters. In this case, however, the load and operating characteristics of the individual motors would have to be known to the user. How long do they run in part-load operation? A frequency converter reduces the energy efficiency of motors operating permanently at full load. It likewise consumes energy and produces a small heat loss, though this is not an advantage here. In other words, the overall energy demand of the drive system, consisting of the converter and motor, increases. In such cases, it is more beneficial to install a soft starter with a bypass. After the motor has run up to speed, the soft starter switches to standby and consumes hardly any additional energy. In the majority of applications, speed control is another good way to save energy.

Adapted analysis periods

Precise system data is necessary to identify precise measures. Systems that record a separate load profile for each drive in continuous operation are useful. The duration of the analysis depends to a large extent on the application. If the process always follows (or should always follow) the same pattern, reliable data will be obtained even if the recording time is limited to a few cycles.

This is no longer true with applications that depend on a particular situation. Typical examples include the air conditioning in a building or a waste water pumping station, both of which are strongly influenced by the weather. An air conditioning system reaches its peak load in very hot summer weather while a pumping station works at maximum capacity in heavy rainfall. If these extreme conditions do not occur during the analysis period, the data may be misleading. This can result in an incorrect design or the selection of unsuitable components and ultimately in poorer energy efficiency.

Control strategy as a key factor

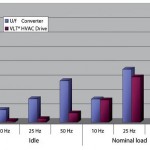

If a frequency converter is used, the choice of control strategy also determines energy efficiency. Generally speaking, the better the strat-egy, the more precisely the converter will control and the greater the potential savings. For example, a simple V/F characteristic – in part-load operation – results in significantly worse results than vector control. This is due to the fact that simple V/F controls often do not consider the current load situation, as they do not perform any additional current measurements.

The picture is altogether different with high-quality controls. These detect the actual motor current, then infer the load situation and respond accordingly. All in all, higher-quality control strategies result in higher energy efficiency of the drives. It should be noted that the least expensive converter is not necessarily the best choice from an economic point of view. The shorter the time for which a motor operates at full load and rated speed, the less profitable the cheaper control strategy becomes.

Avoid oversizing

An optimal design always extends from the machine to the grid and requires an extensive knowledge of both the process and the application. Without this expertise, oversizing due to the inclusion of ‘adequate‘ reserves in the various design stages is inevitable. Unneces-sary oversizing, no matter where it occurs, invariably has a negative impact on feasibility calculations. In practice, this is most likely to be a problem when the electrical and mechanical parts of the design process do not communicate sufficiently or if processes changes in the existing systems are not taken into account. In many cases, higher costs are incurred because an excessively large motor is selected.

The explanation for this is that motors operate most efficiently at the nominal point. Their efficiency decreases at reduced loads, depending on the motor design and power. In the part-load range, therefore, the efficiency of a motor with a high power rating decreases more slowly than that of one with a low power rating. If a motor only achieves 77 % efficiency instead of 80% at the system’s nominal point, significantly higher costs result over the lifetime of the machine. There are only a few, exceptional scenarios where oversizing can make sense and actually improve the efficiency at specific operating points.

Control strategy with a soft starter

Soft starting and stopping are desirable for motors that operate permanently at full load. Many owners prefer soft starters as a more affordable alternative to frequency converters that also allow slight speed adjustments. However, energy-saving strategies are only worthwhile for thyristor controls if the load remains below 45 % over an extended period of time, which is seldom the case in chemical applications. The chances of a realistic payback period are correspondingly slim. The relatively high thyristor losses, which also occur when the motor is operating at full load, are the reason. Transferring the load to the grid is therefore much more effective once the drive has run up to speed, since the losses of a soft starter in bypass mode are typically no more than a few watts. In addition, permanent control produces high harmonics. If the system is frequently operated at part load, a control strategy can pay dividends nevertheless. In instances like this, though, converters that control the voltage and frequency tend to be more efficient.

A further disadvantage of soft starters that likewise affects energy efficiency is the reduced motor voltage. The speed is consequently also lower, which can make the system more efficient due to the slip control. The higher current resulting from the reduction in voltage simultaneously heats the motor to a greater degree and this can shorten its service life. In this case, a frequency converter is recommended.

Hall 11.1, Booth C45

cpp-net.com/0212463

Share: