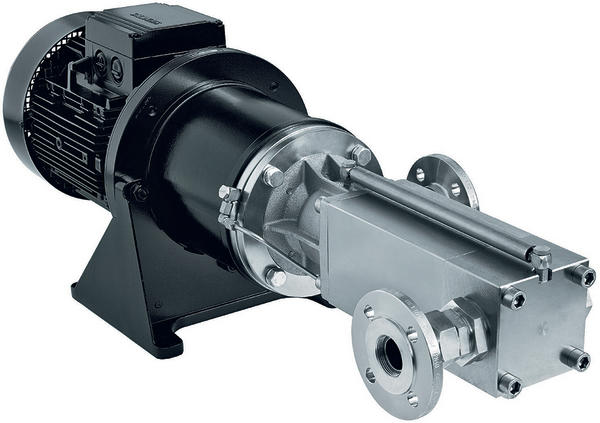

Knoll vacuum screw pumps from the KTSV series are a very good solution for a wide range of dosing and conveying tasks. Compared to conventional systems, these screw pumps are easier to use and much more cost-effective throughout the overall dosing process. The screw pumps are available in six sizes with a maximum capacity of 900 l/min and 150 bar pressure increase, and are suitable for conveying both fluid and high-viscosity media.

High-quality material and precision manufacturing of conveyor components form the basis of reliable, wear-resistant KTSV pump units, which consist of three supporting components: the suction housing, the screw housing with three spindles and the pressure housing. Basic features include special steel screw spindles, hydrodynamic axial thrust compensation, a silicon carbide screw housing, external main bearings and a labyrinth seal for effective pressure release. These components reduce pulsation and ensure high efficiency, low noise levels and a long service life due to extremely wear-resistant materials.

Knoll is able to modify the KTSV pump for special applications as demonstrated for the Swiss cement-manufacturing company Ciments Vigier SA, Pery. Rotary furnaces used by the company are fuelled by used oil and heat ground raw materials to temperatures of up to 1,600 °C. However, the conveyed fuel is highly abrasive because the used oil also contains solvents in different concentrations and solid matter up to 2 mm in diameter. So Knoll developed a corrosion and abrasion-resistant KTSV 50-100 screw pump for supplying fuel to the burner. The pump spindles were manufactured from a wear-resistant sintered material called Ferro-Titanit. As a result, the KTSV pump has operated for more than 7,000 hours without showing signs of wear or malfunction.

cpp 425

Share: