In time for Interkama+ 2005, Bartec, which is celebrating its 30th company anniversary this year, will launch its new Polaris panel PC generation. Polaris has been approved for use in Ex areas, for zones 1 and 2 as well as 21 and 22. The main application areas are the chemical, petrochemical and pharmaceutical industries.

Karl Vogel, Joachim Kraus

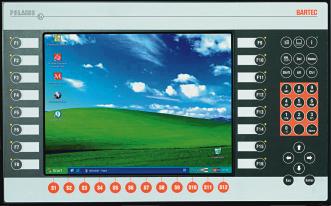

The aim was to offer customers an optimum solution for each and every application, no matter how specific it may be. TFT colour graphic displays are available in 6 different sizes. Another noteworthy development is the display technology. Even with large viewing angles, the contrast remains excellent. A maximum resolution of 1280 x 1024 pixels and a brightness of up to 400 cd/m² guarantee a very good overview at all times. The small 5.7“ displays are eminently suited as human-machine interfaces to control simple machines such as mixers, dryers or fuel filling stations. The medium-sized graphic displays (10.4”) are ideal for operating more complex machines or simple systems such as reactors, centrifuges and ball mills. Complex systems such as pharmaceutical ingredient production lines can be controlled and operated with the 15” and 19” devices.

Wireless data exchange

Thanks to the internal USB interface, wireless data exchange can now be implemented for the first time via WLAN or Bluetooth. Typical WLAN applications include wireless control and visualisation. Internet Explorer is meanwhile also available as a tool, opening up a multitude of potential new applications which have so far only been possible in non-Ex areas.

Polaris is primarily designed for panel mounting, although complete system solutions are available on request, e.g. accommodated in a stainless steel enclosure or as a wall or floor-mounting version with a stand. All PC panels are designed with the q type of protection (powder filling). The electrical connections are laid via a terminal compartment that meets the requirements of the e type of protection (increased safety). All Polaris devices are approved in accordance with Atex II 2G EEx qe ib IIC T4 as well as for use in dusty Ex areas according to Atex II 2D IP6X T80°C.

With this new generation of panel PCs, Bartec has succeeded in transferring the convenience previously reserved for the non-Ex area to the Ex area. The Intel Pentium M processor boasts a remarkably high performance. Its clock frequency of 1.1 GHz corresponds to approx. 1.6 GHz in a P4 processor. The main memory, with up to 512 MB RAM, ensures powerful operator control and monitoring of processes directly on site.

The design of the operator panel front is clearly structured. A polyester foil provides reliable protection against splashwater. This results in the IP 65 degree of protection for the panel front and guarantees trouble-free operation in even the harshest industrial environments.

Hall 7, Booth C30

cpp 437

Bartec Seminars

Visualisation systems

Share: