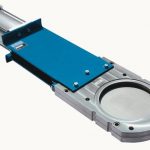

The Multi-slide valve is specially designed for shutting off and metering dry, free-flowing bulk materials. It adapts to the unique process conditions of each application more flexibly and more accurately than any other slide valve concept. The materials, sealing system, flange connections and nominal size can all be optimally tailored. The valve is available in steplessly selectable sizes from DN 150 to DN 600.

Wolfgang Morell

Users of Jaudt Multi-slide valves benefit from total freedom of choice when it comes to materials, nominal sizes (DN 150 to DN 600) and flange connections. The same applies to drive variants: Multi-slide valves can be operated manually, pneumatically, hydraulically or by electric motor. They can additionally be designed as service gate valves, flameproof slide valves or shutter slide gates.

Free passage

Multi-slide valves are distinguished by absolutely free passage. The adapter flange design of these bulk material valves results in a very small overall height. The housing is completely CNC-machined for premium-quality surfaces with roughnesses optionally as low as Ra < 0.8 µm (polished variant). It is also possible to combine various scraper and sealing variants as well as slide blade guides and supports – all with the necessary material certificates and approvals (FDA). Jaudt Multi-slide valves additionally boast the following characteristics:

- Product-tightness in the passage or pressure tightness from 0.3 to 0.6 MPa (depending on the size)

- Product-tightness to the outside or pressure-tightness up to 1.0 MPa

- Approval in accordance with RL 94/9/EC

Numerous design variants

In the simplest variant – the service gate valve – the blade is sealed off from the outside by means of a stuffing box. The flameproof Multi-slide valve (GT type) complies with stricter tightness requirements and is designed for frequent operation. Since the slide valve blade does not have to be moved through the housing, the seal to the outside is absolutely tight. The blade of the shutter slide gate variant features a cut-out equivalent to the nominal size. This allows it to resist extreme conditions when closing with product or satisfy stringent tightness criteria in the passage.

Sealing variants

An Airmatic or scraper seal is fitted inside the passage. Airmatic seals have a special profile cross-section, developed on the basis of endurance tests, and have already been successfully integrated in numerous slide valve concepts. This sealing system guarantees an absolutely tight seal. The pressurised hollow-section seal is only activated when the slide valve is closed. If the slide valve is open, the seal is retracted and lies protected in the supporting slot. The heart of the scraper seal is a sliding, exceptionally hard-wearing labyrinth ring that is adjusted so that there are no crevices to the slide valve blade. It removes any bulk material that has adhered to the blade with every stroke. In combination with the gap geometry (labyrinth), the arrangement of the slide valve blade and scraper ring effectively restricts leakage to a minimum.

Atex certification

The fact that Jaudt Multi-slide valves adapt perfectly to the respective conditions of each application can also crucially influence operating reliability. To take just one example: a customer wants to use Multi-slide valves to discharge iron powder into atmosphere saturated with ethanol vapour. The valves for this particular project have been designed as Atex devices for gas Zone 0 and have the necessary II 1GD approval. Since absolute tightness is stipulated in the passage and to the outside in the vacuum range up to 200 mbar, an Airmatic seal was selected. The electrostatic suitability of this seal for Zone 0 is still being investigated, because the projected area is outside the scope of EN 13463–1.

No problems with abrasive media

In another project currently being carried out by Jaudt engineers, highly abrasive broken glass needs to be discharged via a Multi-slide valve. The specified gas tightness when the valve is closed is achieved by a combination of Airmatic and scraper seals. The sharp-edged bulk material must be kept clear of this area in order to protect the seals against destruction. The solution: differently dimensioned inlet and outlet geometries for the slide valve together with purge air ensure a sufficient clearance between the bulk material flow and the sealing part.

cpp 400

Flexibility – the key to success

cpp: Was 2004 a good year for Jaudt Dosiertechnik and what were the company’s expectations on entering the new 2005 fiscal year?

Roßkopf: In the year just ended, our 46-strong workforce achieved the highest turnover ever reported in the company’s 50-year history – an impressive 5.825 million Euro. This figure encouraged us to kick off the year 2005 extremely optimistically. So far, we have not been disappointed. We have already been kept very busy throughout the first quarter. My hope is that we will manage to exceed the 6 million Euro sales mark in 2005.

cpp: Multi-slide valves are one of your company’s most successful products. What is it that sets them apart from conventional slide gates for bulk materials?

Morell: Rectangular and round slide valves are two of the most popular types. Rectangular slide valves require complex welded designs. Round slide valves are castings that are only offered in a small choice of nominal sizes in the interests of economy. Both components, in other words, are relatively inflexible when it comes to non-standard applications. This is precisely the strength of our Multi-slide valve series for bulk materials. Their dimensions, nominal diameter and sealing system can be optimally adapted to each user’s specific requirements. The same is equally true of the materials that are used.

cpp: Which industries do you mainly target with your Multi-slide valves?

Roßkopf: The majority are sold to customers in plastics processing and in the chemical and food industries.

cpp: Could you cite a concrete example of how this bulk material valve can benefit the chemical industry in practice?

Morell: Our Multi-slide valves are used, for instance, in conveying lines for Macrolon pellets with a grain size of up to 3 mm. These hard pellets used to lead to jamming in the end section of conventional slide valves, with the result that the valves were unable to ensure a tight seal to the vertical column of material. The problem was successfully eliminated with the help of Multi-slide valves, by optimally tailoring the geometry of the housing, blade and guide to the properties of the bulk solid in the runup. The small overall height, free passage and surface quality of our Multi-slide valves proved to be further points in their favour.

More information on the product

Bulk Online

Trade Fair – Powtech 2005

Share: