Intelligent plant concepts are taking hold in all kinds of industrial operations. Comprehensive drive solutions provider Nord Drivesystems offers “Nord 4.0 ready” components, designed to facilitate and further this development. The range of products comprises geared motors, drive electronics and software functions.

The drive is in control

Smart drive systems increase manufacturing efficiency

Intelligent plant concepts are taking hold in all kinds of industrial operations. Comprehensive drive solutions provider Nord Drivesystems offers “Nord 4.0 ready” components, designed to facilitate and further this development. The range of products comprises geared motors, drive electronics and software functions.

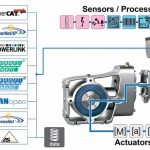

Modern process plants require automation technology with advanced functional intelligence. Components must be able to provide key data from the field via various networks and make a wealth of information available, including data from connected sensors and actuators. In addition, smart field devices are increasingly expected to actively monitor events in the field and react autonomously. Drive manufacturer Nord Drivesystems addresses these demands with a modular portfolio of geared motors, drive electronics and software functions. The differentiated range of distributed drives facilitates the configu-ration of highly economical solutions tailored to a particular application’s characteristics. Featuring an on-board PLC, the inverters can implement logical sequence control. They offer full connectivity for communication with other nodes in the network, including flexible access from a device with a standard Ethernet interface by means of Ethernet tunnelling.

Knowing when to act

The first and foremost prerequisite of intelligent process control – no matter where the controller is installed or how it is connected (by cable or wireless, via Industrial Ethernet or Internet) – is accurate data from the field level. The components themselves must communicate their operating status, to enable conclusions to be drawn about what is happening in networked system segments. There must be appropriate interfaces to allow sensors and actuators to be vertically integrated into control, management and production planning systems, and high quality data transmission must be ensured. Nord frequency inverters therefore monitor and transmit drive data and also collect information from external, digital and analogue sensors and actuators. Moreover, they facilitate condition monitoring and predictive maintenance using software capabilities for efficient diagnostics. These inverters have the ability, for example, to calculate the condition of the gear lubricant and indicate when an oil change is required. They can also autonomously monitor wear on the braking surface as well as the load situation for the entire drive train. Operators can implement predictive maintenance based on such data, thus augmenting plant availability.

Autonomous removal of obstacles

The frequency inverters utilise their versatile sensor interfaces to do much more than just pass on data to a central controller. These drives also react to changing process conditions according to how they have been parameterised. They can realise closed loops thanks to their integral PI controller functionality. In metering applications, for instance, the drives detect the fill level and control replenishment.

In all kinds of process applications, networked drives ensure that any glitches which occur do not normally result in expensive downtime. By monitoring the load situation, the inverter’s on-board PLC is able to detect blockages of pumps, screw conveyors or agitators. By setting suitable drive parameters for glitch sce-narios, the drive will, for example, first attempt to remove a mechanical obstacle by reversing its direction and pulsing. If this effectively resolves the blockage, the drive will then resume normal operation. If the problem persists, the inverter can submit an error signal to the control level and can possibly initiate a fallback procedure, e. g. get other networked drive units to unlock a bypass. The PLC capabilities of these inverters make a significant contribution to higher plant availability and lower service costs.

Application development made easy

Nord also facilitates application development with Nord CON, a user-friendly, free-of-charge programming and parameterisation software that supports drive-related functions according to IEC 61131-3, as well as the PLCopen motion control library. Customer-specific routines can be freely programmed in the text-based “Structured Text” or “Instruction List” languages. All drive-specific functions can be realised directly in the inverter PLC. Users no longer need to spend time and money on the development, verification and validation of application-specific firmware. Furthermore, Nord CON enables remote access via Ethernet tunnelling – for instance, from a notebook with a standard Ethernet interface – giving users very flexible remote diagnostic and maintenance options. Nord frequency inverters can also manage safety applications, notably for implementing Safe Stop 1 (SS1) and Safe Torque off (STO). A library with these safety-related functions is available for free from the manufacturer’s website. It allows machine applications to be verified according to DIN EN ISO 13849 using Sistema, the safety integrity software tool.

Decentralised automation

Distributed drive solutions for simple, low-cost and efficient machine or system designs are still the fastest growing product segment for Nord. Drive systems based on the SK 200E line of frequency inverters are most in demand. They offer the same extensive functionality (including positioning, on-board PLC, safety-related drive functions) as their SK 500E counterparts for control cabinet mounting. These robust distributed units cover an exceptionally large performance range, enabling versatile installations with decentralised process control of pumps, compressors, screw conveyors, etc. and motor outputs up to 22 kW. Moreover, the inverters feature high performance microcontrollers and can control both synchronous and induction motors. The company configures mechatronic drive systems based on three-phase induction motors with efficiency ratings from IE1 to IE3 (Premium Efficiency) as well as IE4 (Super Premium Efficiency) permanent magnet synchronous motors, all of which are manufactured in-house.

The IEC standard motors provide a starting point for simple, easy-to-service and eco-nomical drive concepts. In addition, Nord drive systems combining a motor and an electronics unit achieve the highest level of system efficiency – an IES2 rating according to the current EN 50598-2 European Ecodesign standard.

Hall 15, Booth H31

www.cpp-net.com search: cpp0116nord

Dr. Omar Sadi

Dr. Omar Sadi

Managing Director,Nord Drive Systems

Preview Hannover 2016

Facts & Figures

Facts & Figures

Preview Hannover 2016

Nord Drivesystems has cooperated with pump manufacturers to develop new, single-stage, helical in-line gears with a Nordbloc.1 light-metal casing. These products will be showcased for the first time at the Hannover Messe (Hall 15, Booth H31) as one of the highlights at the exhibition stand. “Nord 4.0 ready” capabilities will be another major focus of this year’s presentation, notably including novel approaches to preventive maintenance of drive systems.

Share: