Flexibility and modularity, plus a high level of quality, are the defining characteristics of this new generation of actuators from Georg Fischer. In conjunction with the new 546 ball valve, the PA 11 / PA 21 pneumatic actuators and the EA 11 / EA 21 electric actuators form an optimally co-ordinated system.

Max Rudin

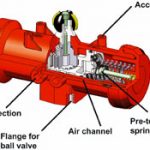

Quality, a long service life and world-wide suitability were the fundamental principles which went into the redesign of the double-piston actuators in the PA 11 and PA 21 type series. By creating two sizes according to the torque of the 546 ball valve series, the size and weight not only of the actuators but also of the entire valve could be kept to a minimum. By co-ordinating the dimensions of the spring assemblies and the diameter of the radius of force at the spindle, it was possible to achieve a maximum torque with a low control air volume. Special attention was devoted to the safety aspect as well as to universal suitability, e.g. internationally standardised connections for the line of accessories and for valve mounting.

The special product features are:

- All-plastic housing in PP-GV, without any metal parts exposed to the environment and therefore extremely resistant to aggressive influences

- Pre-tensioned spring sets for high safety, e.g. during maintenance work

- Selectable with or without manual override by mounting an intermediate piece

- If required, position feedback with the multifunctional module, which also reports the correct valve position with manual use

The actuators are available with an optional stroke limiter for all three functions – FC, FO and DA – for minimum and maximum flow. The control range has a maximum angle of 60°. Valve flanges are available according to ISO 5211: F04 for PA 11, F05 for PA 21 and Namur interfaces for accessories and pilot valves.

Thanks to these built-in features, accessories can be added as needed depending on the application:

- Positioning

- Limit switch kits in Ex design

- 3/2 or 5/2-way pilot valves

- Valve position feedback with mechanical, NPN/PNP or Namur limit switches

- AS-Interface connection

- Stroke limitation for minimum or maximum flow

Electric actuators

Totally new principles and ideas were incorporated in the development of the electric actuators. State-of-the-art technology and function management, which communicates via an internal system bus, form the basis for flexibility and application-oriented modularity.

To the ultimate benefit of customers, the functional design of the actuators was split up in order to achieve maximum flexibility, with the EA 11 being used for standard applications and the EA 21 for applications with more stringent requirements.

The base plate of the EA 11, which receives external control signals in the standard version, drives a motor that is stopped via the internal limit switches when the end positions are reached. An internal current limiter protects the motor against overloading.

Two additional limit switches can be installed as an option. If the actuator is used at temperatures below -10 °C, a heating element is available. Should the customer require a fail-safe application in case of power loss, a fail-safe return module connected to a battery – which opens or closes the valve depending on the setting – can be incorporated.

An optimally designed line of accessories, adapted to the requirements of the future, and the expandability of the equipment are the main strengths of the EA 21 actuator.

In addition to continuous temperature monitoring, a standard ready signal (zero-potential contact) is mounted on the base plate. If a failure is signalled by the base plate or by a monitoring unit, this is reported if necessary to the higher-level control. The function of the actuator can be selected with a switch – open, close or remain in position.

Using additional printed circuit boards for diverse requirements, several extensions or monitoring functions can be realised and integrated. These functions are as follows:

- Four additional limit switches of various types, such as mechanical, inductive, NPN/PNP or Namur

- A heating element and/or fail-safe return, as for the EA 11

- If the customer prefers analogue valve position signalling, a 4…20 mA signal is available. The position of the valve is measured with a Hall sensor and the output signal generated via a processor. For analogue control functions, the actuator can be equipped with a positioner or a PID controller with auto-adaptive parameter setting. For digital serial control, an additional PCB is available for Profibus DP. Printed circuit board C can be equipped with a maximum of four additional accessory functions, thus contributing to customer value.

- Increased control time for the 90° movement

- Monitoring of the 90° control time

- Maximum number of cycles

- Monitoring of the motor current

Discrepancies in the valve, e.g. dry running, can lead to a higher torque and thus a higher motor current. This situation is signalled. If one of the pre-set monitoring values is exceeded, an indication is provided via the ready signal. Once the failure has been remedied, the fault signal must be reset either by pressing the reset button or by switching the equipment off and then on again. These accessories can be used either individually or in any combination. Among the other important features of the EA 11 and EA 21 are:

- All-plastic housing with IP 65 protection (cable gland: IP 67)

- Emergency manual override integrated as standard

- CE, CSA and UL-compliant

- Flame-retardant plastic housing

- All electrical connections can be connected to terminals

Mechanical design of the actuators

A sturdy gear, designed for a long service life, forms the central unit to which the direct current motor is attached. Mechanical modularity is achieved by mounting additional gears and retrofitting permits a maximum torque of 200 Nm. The basic version for the 546 ball valve is sized for a maximum torque of 20 Nm. A standardised flange in accordance with ISO 5211 (F 05) enables the 546 ball valve or another valve to be mounted.

cpp 438

Share: