The four rheometers in the Physica MCR series cover tasks from simple quali- ty control to demanding R&D work. These rheometers are remarkable for their high measuring accuracy, simple operation and comprehensive range of accessories. Their special features include an automatic geometry and accessory detection system and a patented system for determining the actual measuring gap.

When developing this rheometer series, Anton Paar GmbH worked on the premise of three levels, each with different requirements: industrial quality assurance and production control, product research and development and rheological research. The result: a family of four rheometers (the Physica MCR 51 – the only model in the series with a ball bearing – MCR 101, 301 and 501). Each model meets very different requirements but is completely compatible with the other models in the series. Their operation, accessories and geometries are identical. A wide range of measuring systems, temperature control devices, geometries, special accessories and software solutions are also available. The special features which make the Physica MCR series so unique are:

- Toolmaster – the automatic recognition system for measuring systems and accessories

- TruGap – the patented measuring gap detection system

- The air bearing EC motor

- The RheoPlus software

Toolmaster

Toolmaster, the automatic component recognition system (patent pending), ensures that the rheometer automatically recognizes all measuring geometries and cells as soon as they are connected to the instrument. The components are connected using the QuickConnect quick-fitting coupling. A transponder chip integrated in the geometry contains all relevant geometry data, which is automatically transferred to the software. The data from the connected temperature control system is initialized by SmartLink and the component serial number is also transferred to the software, ensuring clear documentation of all measuring systems. This generates the following benefits:

- No more errors as a result of users inserting the wrong geometry

- Intelligent autoconfiguration system for user-specific rheometers

- Calculation of exact geometry factors using real geometry data, e.g. truncation, diameter and cone angle

- Error-free documentation of the configuration

TruGap function

TruGap allows the user to monitor and control the actual measuring gap in cone/plate and parallel plate measuring systems. The patented technology is based on an induction method and determines the exact gap size, thereby eliminating sources of errors. The TruGap function is available for use with Peltier elements, electric heating and convection heating and can be employed across a wide temperature range. The measuring gap can be determined independently of the test type at all times.

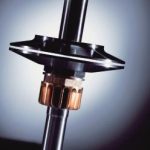

Drive system

The air bearing EC motor is one of the key components of the MCR series. The electronic, frictionless commutation of the motor, together with the air bearing, guarantees absolute motor torque calibration due to the linear relationship between the electromagnetic torque of the motor and the stator current. Absolutely no heat, which could change the motor characteristics and lead to signal drifts, is created. The technical specifications are as follows:

- Torque range of more than seven decades

- Speeds set as low as 10–6 min-1

- Precise speed control over a range of more than nine decades

The air bearing and EC motor ensure drift stability. A patented normal force sensor located inside the air bearing performs a capacitive measurement and detects the change in the rotor position due to applied normal forces. The result: precise normal force measurement with minimum drift and maximum thermal stability. A high-resolution optical encoder using data oversampling technology enables accurate measurements of the angular deflection. With the DSO method, it is possible to control oscillatory strains as low as 0.0001 mrad.

RheoPlus software

The RheoPlus software was developed according to ISO 9001 guidelines and runs as C/C++ software under the latest Windows operating systems. The electronic signature, audit trail, archiving and retrieval of data comply with the regulations in 21 CFR Part 11 published by the US Food and Drug Administration (FDA).

If measuring results from different instruments in the laboratory need to be archived in an external database, this is possible using the LIMS-SAP interface. Measuring profiles can also be activated via the interface by other programs, allowing users to work through the script. RheoPlus can communicate with the measuring instrument via a serial or Ethernet interface.

There are no limits with regard to programming and linking test sequences. Rheological tests can be combined in real time in whichever order required. Additional instruments or signals, such as power supplies, relays and magnetic valves, are supported by the software in real time and can be synchronized with the rheological measuring profile. This makes RheoPlus the ideal platform for setting up measuring procedures that simulate processes and applications.

cpp 434

Share: