Whenever the amount of fluid being pumped to a process is critical for quality control of the end product, the SMP pulse-free pumps in the HY series provide an ideal solution thanks to their high pumping accuracy of ± 0.1% and their excellent repeatability, even with difficult-to-handle fluids such as gelatines, isocyanates, polymers, monomers or – subject to certain reservations – media with a tendency to form soft or hard slurry.

Yahya Rashid, Suzuki Keij

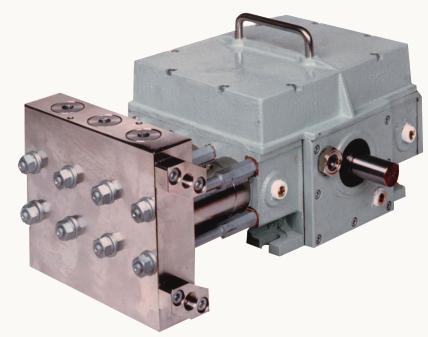

The HY series of super metering pumps (SMP) from Fuji-techno industries comprises five types and 22 models capable of handling fluids from 2 to 200 MPa. They cover a wide pumping range from 0.1 ml/min to 100 l/min. Although plunger-type pumps, these SMPs were designed with both operational and cleanliness aspects in mind, cleanliness being one of the important criteria for easily solidifying liquids as well as in the food industry. SMPs are also the ideal choice for shear-sensitive or viscous polymers owing to their slower stroking rates with pulseless flow. They are moreover completely flushable. When pumping hazardous fluids, such as isocyanates that can react with the moisture present in the air, strict separation of the air from the liquid is vital. The SMPs optionally allow purging with an inert gas like nitrogen to facilitate working with media of this kind.

Special cam design

The special cam design of the triplex plunger pumps enables the three plungers to be optimally synchronized, so that the total plunger velocity remains constant and the pulsation effect is consequently negligible. The system is designed such that each cam revolution of the three plungers consists of six 60° phases of movement. The plunger restoring device permits a constant pumping stroke even with highly viscous media, and there is also no change in the discharge volume. SMPs can handle all fluid viscosities from 0.01 to 1000 P. The fluid pumping level can be precisely controlled, even if the viscosity and pres-sure of the pumped fluid vary. A special jacket can be supplied for all SMP models to protect the pumps against extreme media temperatures (-30 to +200 °C). Coating, injecting, spraying and mixing are among the typical precision pumping processes. SMPs vastly improve their operating efficiency.

cpp 405

Share: