Besides hygienic design and validation requirements the most important selection criteria for pharmaceutical pumps are safety and reliability. In this case hermetically sealed diaphragm pump technology is an excellent choice. The modular Lewa ecoflow metering pump product line includes sanitary and hygienic designs. Lewa ecoflow sanitary and hygienic pumps comply with the specific design and material requirements of the Biopharmaceuticals industry.

Dr.-Ing. Hans-Joachim Johl

The general application flow range for these metering pumps covers about 0.1 l/h to 10 m³/h. Multiplex pumps allow for larger flows. The maximum discharge pressure for sanitary and hygienic pumps with PTFE diaphragms is 400 bar. The temperature range is between -40 °C and +150 °C. The pumps are perfectly suited for metering liquids in a wide viscosity range (from 0.1 to 100,000 mPas). Their hermetically tight construction handles various life science and industrial fluids including:

- Sterile fluids for metering (proteins, cultures, buffers, blood plasma)

- Highly pure fluids (pyrogene-free vaccines, supercritical CO2, for cleaning of nanostructures)

- Valuable metering fluids (additives such as modifiers, extracts, volatile oils)

- Fluids with poor lubricating properties (solvents, liquefied gases)

- Fluids that react with the atmosphere (sodium silicate, sodium, aluminium alkyl)

- Fluids that are radioactive, explosive, toxic, abrasive or corrosive

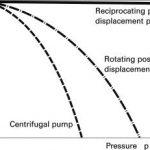

Metering pumps are unique with their stiff flow and pressure pumping characteristics. This means that flow is nearly independent of discharge pressure. There is a linear dependence between flow, stroke length and stroking frequency.

The basic design of a diaphragm pump is similar to a plunger pump, except with a diaphragm hermetically separating the process fluid path from the hydraulic chamber. This assures leak free operation and safety against contamination. Plunger pump heads with their potential risk of contamination from plunger seals are incompatible with biopharmaceutical industry requirements, and are often rejected strictly by design. However, this does not apply to homogenizing systems which are still designed around multiplex plunger pumps. Lewa diaphragm pumps do not have a plunger seal, a permanent weakness in standard plunger pumps. Diaphragm materials are available in virgin PTFE or stainless steel.

Modular hygienic pumps

Specific customer requirements such as material certificates, cleanability (CIP, SIP), standards and directives (e. g. European standards, EHEDG guideline document no. 17, 3-A standard no. 44-03, ASME BPE 2002) and the necessity to economically meet these requirements has led to further development of existing pump designs. Beginning with the proven standard industrial pump, Lewa create a modular hygienic diaphragm pump design with:

- Drive series in standard sizes

- Pump heads with specific materials of construction suitable for a range of flow rates and discharge pressures

- Minimum product chamber volumes

- FDA materials of construction in accordance with the application requirement: Hygienic: Standard material 1.4435 with <1 % delta ferrite content, electro polished and passivated. Sanitary: Standard material 1.4571, mechanically polished

- Various options for pipe connections, e.g. triclamp or sterile flange

- Single or variable speed motors

- Instrumentation options including speed transmitters and pressure switches

Note that individual pumps may be combined in a multiplex design.

Variable eccentric drives

The variable eccentric drive unit works in more than one hundred thousand machines installed worldwide in a variety of metering pump applications. It is the muscle of the diaphragm metering pump, converting rotating movement into an oscillating stroke action. It is easy to operate and extremely sturdy. Some of the outstanding features of the variable eccentric drive include long service life, low maintenance cost, long service intervals, a high mechanical efficiency and excellent safety against overload or dry operation. The linear and precise stroke adjustment is controlled manually, electrically or pneumatically. Setting of the stroke length is possible while the pump is running or stopped.

Safe and hygienic diaphragm pumpheads

The outstanding features of the Lewa ecoflow M900 pumphead series are safety, economic efficiency and reliability. The modern M900 series is equipped with a positive-positioning, multilayer PTFE diaphragm assembly. This design is now standard in this product line. A monitoring system reliably monitors diaphragm condition during normal pump operation. The pump may be configured to run after a diaphragm failure until maintenance can be performed. Alternatively, the drive motor may be configured to shut the pump down immediately. The M900 series includes automatic control of diaphragm movement. This device synchronizes diaphragm motion with the stroking action of the hydraulic plunger. This new approach offers reliable protection of the diaphragm from upset conditions. The diaphragm position control and monitoring systems form the DPS (Diaphragm Protection System).

Many user-related, custom designs are available for the pump heads. These include special valves for fluid suspensions, a variety of connection designs (e. g. DIN-sterile flanges, Tri-Clamps, aseptic and metallic sealing), heating and cooling jackets and special materials (e. g. Hastelloy, plastics).

cpp 400

Share: