The ESS30-S electronic circuit breaker and the Module 18plus power distribution system provide a flexible and reliable solution for applications in process automation. The advantages of electronic protection compared to traditional, thermal-magnetic circuit breakers are significant. When using switch mode power supplies, the available current is normally limited to 1.5 times the rated current. Control cabinets are usually equipped with switch mode power supplies rated for 10 to 40 A. This means that in the event of a short circuit, the maximum current can briefly reach a value of 15 to 60 A. This is not sufficient for quick magnetic disconnection of the thermal-magnetic circuit breaker. As a result, the power supply is overloaded. In this case, it protects itself by reducing the output voltage automatically, leading to a voltage dip at all connected loads rather than just the affected circuit. Hence, the failure of a single device can cause the whole system to malfunction. The ESS30-S electronic circuit breaker protects the power supply against overload and prevents one small failure from shutting down a complete system.

The active current limitation limits the current to 1.2 times the rated value in the event of a short circuit or overcurrent. Overload of the power supply is effectively prevented, as is a breakdown of the entire supply voltage. If a short circuit occurs, the ESS30-S ensures electronic disconnection after 150 ms. The circuit is physically isolated after 5 s.

Physical isolation

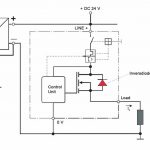

Standard electronic circuit protectors normally do not offer physical isolation. They are fitted with a power Mosfet to disconnect or switch off the load circuit. If the Mosfet is conductive, its low resistance allows current to flow through the electronic circuit protector. If the power Mosfet is blocked, it has high impedance and thus prevents current flow. High resistance of the Mosfet, however, cannot prevent leakage currents from flowing in the blocked state. In addition, each semi-conductor switch has an integral inverse diode. In the event of a linked failure on the load level, the diode may allow a direct return supply from this level to the 24 V(DC) level. Additional physical isolation ensured by the electronic circuit protector would prevent such a return supply. This physically isolating switching element is connected in series with the power Mosfet. A short circuit causes the Mosfet to first of all disconnect the circuit electronically and protects the switch mode power supply against overload. This happens within 150 ms. The electronic circuit breaker has an additional mechanical switching element which opens the load circuit within 5 s in the event of a failure, creating a clearance so that the circuit is physically isolated. Hazardous system conditions are reliably prevented. In addition, a faulty return supply to the 24 V(DC) control level can be ruled out.

Modules increase hazard potential

Modular system and plant designs will become increasingly prevalent in the chemical and pharmaceutical industries in the coming years. The importance of power distribution and wiring in the field will continue to grow. In conduits or drag lines, there are often a large number of cables laid in parallel. Although separating the different voltage levels is a requirement, it is very often not implemented in practice. Particularly with existing systems, space is limited and so are the installation options. A return supply of the 230/400 V(AC) load voltage to the control voltage level can have catastrophic consequences. The ESS30-S limits the failure by means of physical isolation, so that only one circuit is affected. Damage to the entire system at once is excluded. The ESS30-S provides extra safety and increased system availability. This is the reason why major German chemical companies request not only electronic protection in their plants but also physical isolation. In addition, as described above, leakage currents may cause the circuit protector’s visual status indication to glow. Service technicians are frequently unsure about what to do in such cases, so that they eventually decide to replace the installed devices. Today, the chemical company in question relies exclusively on electronic circuit breakers with physical isolation.

Perfect power distribution

E-T-A’s ESS30-S is ideal for use in the chemical and pharmaceutical industries because it combines active current limitation with physical isolation. It unites the advantages of an electronic circuit protector with the added value of physical isolation. It is due to this function that the ESS30-S is approved to DIN EN 60934 as a circuit breaker for equipment protection. In combination with the Module 18plus, it forms a modular and flexible power distribution system which offers a complete overview of the 24 V(DC) supply and allows a modular design, tailor-made to the plant’s requirements. Enhanced flexibility and reduced wiring time are further advantages. The system also includes a supply module for up to 80 A. A busbar system provides interconnection of all modules. Owing to the plug-in design, the individual circuit breakers can be exchanged at any time and system adjustments implemented easily. The integral group signalling rounds off the system.

Online search: cpp0218eta

Hall 11.0, Booth C43