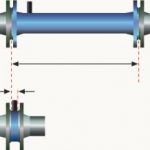

The Compact static mixer achieves high-quality mixing over very short distances by the simplest technical means, including a small pressure drop. It is clamped between two pipe flanges and the installation length accounts for only 40% of the nominal pipe diameter. No additional flanges are necessary.

Markus Fleischli

Static mixers are an efficient and reliable solution if two components have to be mixed homogeneously or brought into contact with one another in a continuous process. They are found in various designs to suit different applications. In this respect, it is important whether the flow in the mixer is laminar or turbulent. In the case of laminar flows, the components are distributed progressively in thinner and thinner layers, whereas eddies are created in the case of turbulent flows.

A traditional static mixer comprises a housing that is usually welded together from a pipe and two flanges. It contains several mixing elements. If necessary, the housing is fitted with a port or socket through which an additive can be fed.

Only one mixing element

With its Compact model, Sulzer Chemtech has now introduced a mixer onto the market that is quite different: it comprises a narrow ring (without flanges) that is clamped between two pipe flanges. A single mixing element, together with a dosing port for additives, is integrated within this ring. The mixing element comprises three blades with specially shaped edges to break up the flow. The additive is fed behind the central blade. The mixer is designed for turbulent flow.

Simple installation

The development goal was to reduce the installation length significantly compared with traditional mixers, without incurring a greater pressure drop. Existing mixers either have a short insertion length and a large pressure drop or a small pressure drop but a longer installation length. Other objectives were simple design, installation and cleaning. In addition, it was necessary to minimise the overall purchase, installation, running and maintenance costs.

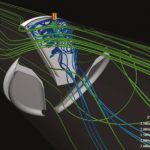

A large number of experiments and CFD (computational fluid dynamics) calculations have confirmed that these goals were achieved:

The installation length (the space required between the flanges) accounts for only 40 % of the nominal pipe diameter. One result of this minimal space requirement is that the Compact can be inserted between two flanges of a pipe – an exceptionally simple and economical method of installation. Homogeneous mixing is already achieved three pipe diameters downstream of the mixer. The mixing length is therefore significantly shorter compared with conventional static mixers. he mixing quality is independent of the mixing ratio. The pres-sure drop is similar to that of conventional mixers, which is particularly remarkable given the short installation and mixing lengths. The mixer does not block and is easy to clean, thanks to its geometry. The Compact is available with six standard pipe diameters: 25, 40, 50, 80, 100 and 150 mm (other sizes available on request).

Flexible manufacturing

Even in the manufacturing area, new paths were trodden. For the first time, a mixer (including the ring) was milled from one solid block. This manufacturing method turned out to be particularly advantageous, at least for nominal pipe diameters up to 100 mm – larger mixers will continue to be welded as before. In contrast to the casting method, there are practically no investment costs. Furthermore, the production technique is very flexible with respect to the type of material and geometry.

cpp 436

Share: