The heating concept was utilised in the design of the Vortex Pilot Gas Heater and the Vortex Farm Tap Station. The proprietary Vortex Heater (VH) releases the internal energy of a decompressed gas flow and converts it into a highly intensive thermal flux. The generated heat is then used to heat up a separate gas flow (pilot gas, instrumentation gas, etc.) as well as for self-heating (non-freeze provision) to overcome the Joule-Thomson temperature drop in the gas flow as it expands in the VH’s inlet nozzles.

Dr. Lev Tunkel

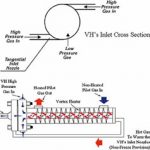

The Vortex Heater is an apparatus with no moving parts. It is shown in Figure 1 incorporated into the Vortex Pilot Gas Heater. The VH is comprised of a tube plugged at one end, a tangential inlet nozzle located at the other end and a single discharge opening arranged close to the inlet nozzle’s cross section. During VH operation, the inlet nozzle is fed with a high-pressure gas. The discharge opening serves as an exit for a low-pressure gas. The VH is a pressure reducing device by virtue of its relatively small inlet tangential nozzles. A high-pressure gas undergoes pressure reduction and flow velocity increase as it expands in the VH’s inlet nozzle. As a rotating (vortex) flow travels down the tube at high speed, the gas kinetic energy moves from the vortex inner layers to the outer layers. As a result, two currents with different energy (e.g. with a different temperature) are formed in the tube: inner/low temperature and outer/high temperature. The outer current’s thermal energy penetrates the walls of the VH and can therefore be utilised to heat a separate gas flow as it travels through a heat exchanger mounted on the VH’s outer surface. The low and high-temperature layers coexist in the VH, merge at its single discharge orifice and exit the VH through this orifice. The merge negates the vortex temperature division; the discharged gas temperature therefore only differs from the VH’s inlet gas temperature by the value of the Joule-Thomson temperature reduction. Prior to merging with a cold fraction, a portion of the VH’s hot flow is used to heat up the unit’s inlet nozzles in order to maintain its non freeze performance.

Vortex Pilot Gas Heater

The Vortex Pilot Gas Heater (VPGH) from Universal Vortex, which is based on the VH concept, is a heating device for pilot-operated gas pressure regulators. A gas flow taken from the high-pressure delivery line upstream of the gas pressure regulator enters the VH, undergoes pressure reduction and temperature division and is then discharged from the VH into the low-pres-sure delivery line downstream of the pres-sure regulator. Since the VH flow is a small fraction of the entire flow, the gas pressure at the VH discharge is always equal to the current gas pressure in the delivery line downstream of the regulator. The unheated pilot supply gas taken from the high-pres-sure delivery line upstream of the gas pressure regulator is directed to the heat exchanger mounted on the walls of the VH. As it moves along the VH walls, which are equipped with heat transfer elements (fins), the pilot gas absorbs heat radiated by the hot portion of the vortex flow. The heated pilot gas is then supplied to the control pilot, where it undergoes the required pressure reduction and simultaneous Joule-Thomson temperature decrease. However, since the heat which the pilot gas receives from the VH is more than the value of the Joule-Thomson effect, the depressurised pilot gas in the control pilot remains under thermodynamic conditions that prevent it from freezing up. It should be emphasised that the VPGH design envisages two hydraulically separate gas circuits: the Vortex Heater flow and the pilot gas flow. These flows only interact by exchanging their thermal energy. In order to comply with zero downstream gas flow demands, a shut-off valve is installed upstream of the VH inlet. This shut-off valve (usually a Fisher 627 pilot), which is monitored by the pressure sensor connected to the low-pressure line downstream of the pressure regulator, provides overpressure protection for the downstream system and must be shut off or closed if the downstream pressure exceeds the setpoint. The valve normally operates in the fully open position, so that the high-pressure VH supply gas is unrestricted. It is advisable to maintain the Fisher 627 pilot setpoint just above the setpoint of the pilot-operated pressure regulator. In this case, with high flows, both the main regulator and the VH are open and the VH acts like a fine-tuning pressure regulator, generating heat as an outcome of the gas pressure reduction. With low flows, when the downstream pressure increase shuts off the main regulator, the VH continues (within the set pressure limit of the Fisher 627M) to deliver its relatively small flow to the downstream line, thus operating primarily as a gas pressure regulator and flow control device. If the pressure regulating system is restarted, the high setpoint allows the VH to resume heating the pilot gas prior to opening the main gas pressure regulator. The VPGH, which is a single-size unit, has proved that it can operate efficiently over a broad range of parameters, even handling a single pressure cut of over 1000 psi gas pressure differential.

The main features of the VPGH are:

- adds up to 32 °C to the pilot supply gas

- heats pilot gas as an outcome of the routine gas pressure reduction

- non-freeze single pressure cut of over 69 bar gas pressure differential

- no lost gas

- no chance of overheating

Vortex Farm Tap Station

A gas flow taken from the high-pressure line (usually a transmission pipeline) enters the VH, undergoes pressure reduction and temperature division and then, as two vortex currents with different temperatures merge at the VH outlet, is discharged from the VH into the low-pressure (usually underground) delivery line.

Discharged gas then exchanges heat with the ground and finally assumes the ground temperature. The intensity of the heat exchange is very high due to the small VFTS actual gas flow rate. The VH is connected to the high-pressure line by means of a Fisher 627M pilot. The Fisher 627M is installed with its pressure sensor connected to the low pressure line downstream of the VH. It provides overpressure protection for the downstream system and must be shut off or closed if the downstream pressure exceeds the setpoint. The Fisher 627M normally operates in the fully open position, so that there is no pressure reduction upstream of the VH. The VH’s inlet orifice, which, by design, is just a fraction of the Fisher 627M orifice in its wide-open position, inherently limits gas flow through the Vortex Farm Tap installation. With high VFTS flows, the discharge pressure is low, the Fisher 627M is open and the VH is operational. If the gas demand decreases, the increasing downstream pressure exceeds the value of the Fisher 627M set pressure, thus forcing it to close. The VH gas supply is reduced to zero and the VFTS is shut down. If the gas demand increases, the decreasing downstream gas pressure opens up the Fisher 627M and the VH returns to operation. The main features of the VFTS are:

- external heating not needed to provide non-freeze gas pressure reduction

- generates heat as an outcome of gas pressure reduction and uses it for self heating

- single pressure cut

- no lost gas

- no conventional pressure regulator required

cpp 434

Share: