WirelessHart technology offers the right amount of dependability and robustness to guarantee the required process reliability and avoid expensive downtime. The software update for the WirelessHart Modbus gateway from Pepperl+Fuchs offers improvements and enhancements to existing features as well as other features that are completely new. As a result, planning and simulating such networks will in future be more efficient. In addition, fault detection and troubleshooting during operation are optimised.

Software update for WirelessHart gateway

More comfort during operation and start-ups

WirelessHart technology offers the right amount of dependability and robustness to guarantee the required process reliability and avoid expensive downtime. The software update for the WirelessHart Modbus gateway from Pepperl+Fuchs offers improvements and enhancements to existing features as well as other features that are completely new. As a result, planning and simulating such networks will in future be more efficient. In addition, fault detection and troubleshooting during operation are optimised.

WirelessHart is the technology of choice when it comes to establishing wireless network structures for process automation. Wherever conventional cable connections are too time-consuming to route in extensive and difficult-to-access installation structures, WirelessHart combines wireless communication with the benefits of Hart technology. The key elements and centres of communication in every WirelessHart network are the WirelessHart gateways. They act as interfaces between the field devices, including adapters and the process control system. These are connected to the WirelessHart gateways either via Modbus or via EtherNet/IP. Using the Network Manager, the gateways decide when individual WirelessHart field devices and the respective WirelessHart adapters should send their data and which paths they should use to do this. They are also equipped with a Security Manager to encrypt communications securely and make them bug-proof. With the latest software update for the Modbus gateway, Pepperl+Fuchs offers a wide range of new features for optimum fault detection and troubleshooting, which simplify and accelerate commissioning while improving diagnostic options during operation. In addition, the implemented security features ensure an even higher level of network security and optimised rights management.

During commissioning, the gateway supports the customer with the factory acceptance test, which simulates whether a gateway is sending the correct values to the process control system and whether these arrive at the right destination. User-defined values can be entered in the substitute value list even before field devices or adapters are added to the network. If the process control system receives these substitute values from the gateway correctly, the simulation test is passed and proof of function is provided to the process control system level.

Diagnostics during operation

One new function that particularly satisfies the network operator’s high requirements for reliability during operation is the “stale value” – a display that shows the age of a sent value, e.g. a cached dynamic variable, or of command 48 (status information).

A time stamp is assigned to any burst message that is received by the gateway. The configured burst period can be calculated for every cached value in this way and specified as a percentage. If a gateway receives a new value from the field device, it starts counting again from the beginning. An alarm is then generated based on the user-defined warning level (e.g. 150 % burst period) or fault level (e.g. 300 % burst period) as soon as a burst message has exceeded its specified update period and is overdue. Much like a traffic light, the gateway shows the age of a burst message in green if the measured value is not older than 100 %, in amber as a warning of temporary communication problems or in red to alert the user to a complete communication failure. Communication failures can be triggered, for example, by radio interference or as a result of mobile obstacles in the field.

Moreover, in the event of a fault, a substitute value can be displayed for all four variables (PV, SV, TV, QV). The last value, NaN (not a number), can be defined as a substitute value, in other words a specific bit combination that is defined in Spec, or upscale or downscale. Users can also define their own substitute values. This new control function therefore offers the plant operator optimal, fast and situation-specific troubleshooting.

Enhanced security

An essential part of the new software update relates to security requirements. The implemented user levels ensure that plant operators can only read and update values while administrators have both read and write access. Unauthorised manipulations are excluded. During network expansions, a whitelist secures the network in addition to the join key and the network ID. This means that new devices can only be added to the network if their address is entered in the whitelist.

The whitelist can be expanded by the plant operator whenever new adapters or field devices are added to the network. To do this, a temporary join key is defined and a time set to determine how long this key will be active. The network is opened up at the same time. If the new adapter or the new field device is implemented, a corresponding entry is added to the whitelist. If a new adapter requests to join the network with a join key and network ID, it is not added to the network if there is no entry in the whitelist. Furthermore, the plant operator can permanently change the join key for all adapters and field devices connected to the network at any time. This represents an especially high level of security, in particular if there are changes to the group of individuals with access authorisations, such as after commissioning or receiving services from service providers, etc.

Centres of communication

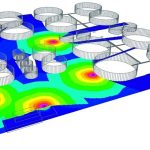

Apart from the newly implemented features, the gateways support the entire life cycle of WirelessHart networks with exactly the right tools. A plant can be displayed using a 3D tool (Wireless Network Checker). This makes it possible to model plants according to the ambient conditions. The modulation tool lets users create 3D models of plants and buildings with complex structures and with a level of detail of their choice. Even existing plans can be imported easily. Following this, the propagation of radio waves and the connectivity between each network node are accurately simulated using the simulation software. This allows different network designs to be simulated, which considerably reduces the time required for commissioning and optimises how the devices are used.

During operation, the communication paths and the quality of the connections in the gateway are coloured from green for very good to red for no connection. Thanks to this feature, the “topology view” gives a quick overview of a WirelessHart network’s quality during operation, so that potential single points of failure can be identified and eliminated straight away.

In addition, the flexible Modbus mapping makes it easier to set up a network. Under normal circumstances, Modbus addresses are automatically assigned based on when a device first joins the WirelessHart network. Owing to this ability for self-organisation, it is not possible to determine which Modbus address a device or a Hart variable has in advance.

Flexible Modbus mapping enables the Modbus register to be imported or exported via a CSV file; Modbus addresses can be sorted based on different variables and existing Modbus addresses may be modified. With just a few mouse clicks, customers can create a map that is adapted to their individual needs.

Suitable for worldwide use

Many possibilities are offered to permit users to set up and operate a network optimally, from the planning software through configuration and commissioning to diagnostics. With its new software update for the WirelessHart gateways, Pepperl+Fuchs has optimised the setup, new installation and modification or expansion processes for WirelessHart networks. Fault detection and troubleshooting have also been improved and high security requirements are now fulfilled. Pepperl+Fuchs has simultaneously extended its range of supported languages. Being able to operate the DTM or web interface in different languages makes global operation even more convenient.

www.cpp-net.com search: cpp0216pepperl

Sabrina Weiland

Sabrina Weiland

Product Marketing Manager,

Business Unit Automation,

Pepperl+Fuchs

Share: