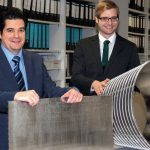

For a few months now, Steinhaus’ Optima series has also included high precision filter tubes. In an interview with cpp, Carsten Dietz and Ulrich Tunger explain why this separation technology specialist has added filter tubes to its product portfolio, which other components the family includes and what Fito and Foti are all about.

Slotted screen panels and high-precision filter tubes

It’s the diversity that does it

For a few months now, Steinhaus’ Optima series has also included high precision filter tubes. In an interview with cpp, Carsten Dietz and Ulrich Tunger explain why this separation technology specialist has added filter tubes to its product portfolio, which other components the family includes and what Fito and Foti are all about.

Mr Dietz, what products are there in the Optima product range?

Carsten Dietz: The series includes slotted screen panels, high-precision filter tubes and screen modules. The last-mentioned are used mainly in the quarry and pit industry. These standardised screen panels can be changed very quickly by means of a clip fixture and can be used extremely flexibly.

Up until recently Steinhaus marketed high-precision filter tubes separately. Now they are part of the Optima series. What made you decide to take this step?

Ulrich Tunger: We’re hoping for synergies in marketing. Ultimately, these products are targeted at similar groups of customers, who will profit from joint presentations at trade fairs, in brochures or on the Internet.

Dietz: Furthermore, from a design perspective, high precision filter tubes are no different from slotted panels. Both consist of sharp-edged, drawn profile wires, which are fastened to crossbars accurately and with high quality using a resistance welding process. The screen panels produced in this way have a markedly finer gauge quality than conventional perforated screens, because high precision filter tubes generally have smaller slot widths than slotted screens. This similarity of design was a further reason to market both products together in the Optima series.

What kinds of processing work can be done with Optima products?

Dietz: The products can be used for many kinds of processing work. They function as filters in solid-liquid separation or like a sieve for grading solid materials. Another, totally different area of application is drying technology, where they’re used as inflow panels. That’s the case in systems for drying hops, for example.

If we could stay with filtration and screening for a moment: both processes place heavy mechanical loads on Optima components. How do you protect them against wear?

Dietz: There are basically two ways: one is to select suitable materials and the other is to modify the profile geometry of the wire forming the slots.

Modify the profile geometry? Could you please explain what you mean by that?

Dietz: Normally, we work with wires which have a triangular cross-section. They form the slots. This wire geometry has two main advantages: it’s virtually impossible for the individual slots to become blocked and, on the whole, widening the slots in the direction of filtration prevents blockage by near-mesh-sized particles. Abrasive wear on the profile surface can cause the slot width to become enlarged. This can be avoided by using wires with a double-wedge profile, for example. Although they don’t eliminate wear completely, the wider flanks stop the slots from getting any bigger.

What materials are used to make Optima products?

Dietz: Various steel grades. The quality we choose depends on the application, of course. It could be anything from low-alloy grade through various high qualities to duplex or superduplex material.

Can the service life of the screens and the high-precision filter tubes be increased by surface refinement?

Dietz: Yes. That’s actually the third method we employ to provide our customers with products that have a long service life. We work here with hard-chromed and Tenifer-hardened surfaces.

Optima products have to meet high quality standards in order to achieve the desired separation and extraction levels. How do you ensure the quality of these high precision products?

Dietz: We use special, computer-assisted welding machines to manufacture the slotted screens. These machines enable all important welding parameters to be monitored continuously as the basis for our quality products. We naturally also monitor the quality of the finished slotted screens.

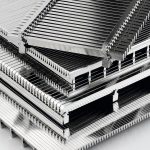

Could we now talk about some of the products in the Optima family? I’d like to start with the slotted screen panels. What variants do you offer them in?

Dietz: Our slotted screen panels are available in flat or curved designs. One important application for flat panels is screening machines for grading and dewatering solid materials. Curved slotted screen panels are used as static filters in sieve bends or as slotted wedge-wire screen baskets in centrifuges of the kind manufactured by our sister company, Siebtechnik.

How are slotted wedge wire screen baskets made out of bent slotted screens?

Dietz: By putting together bent slotted screen elements to form a basket. The cylindrical screening baskets needed for decanter centrifuges can also be made in this way.

Which slot widths do you offer your slotted screen panels with?

Dietz: We can supply these products with any slot width down to 6 µm. However, that’s a purely theoretical figure that hasn’t yet actually been asked for in practice. Slot widths of 20 µm and upwards are most common.

The Optima family also includes high precision filter tubes. These are likewise offered by Steinhaus in different variants. Mr. Tunger, could you tell me what they are

Tunger: We offer high precision filter tubes in a radially slotted and an axially slotted version. The profile wires forming the slots on the radially slotted version are spirally welded around crossbars, so that the crossbars are on the inside. On the axially slotted version, the profiles run parallel to the longitudinal axis of the slotted screen cylinder. The supporting crossbars are wound around the profiled wires from the outside.

And then you also distinguish between Foti and Fito variants. What are these abbreviations all about?

Tunger: Foti stands for filtration outside to inside, meaning the filters are flowed against from the outside. If the high precision filter tubes are flowed against from the inside, we speak of filtration inside to outside, in other words Fito.

How do the two variants differ in design?

Tunger: On the Foti variant the wires forming the slots – which, as I mentioned earlier, usually have a triangular cross-section – are fixed to the inside crossbars by their sharp end. That means that the working side and the filter surface are smooth. On the Fito variant the triangular profile wires are welded onto the support bars on the inside by their flat end. The smooth working side is on the inside but it’s interrupted by the support or crossbars.

Don’t the inside crossbars on the radially-slotted version of the Fito design make the filter tube more difficult to clean?

Tunger: These filter tubes can be cleaned without any difficulty by back-flushing. However, mechanical cleaning by means of wipers or blades, for example, is not possible with this version. For applications that require mechanical cleaning, the portfolio includes high precision filter tubes in the axially slotted design as well as the Fito variant.

One very new addition to the Optima product family are the high precision filter tubes with square holes. Could you please tell us more about this version?

Tunger: These high precision filter tubes can be flowed against from both the outside and the inside. We’ve therefore combined both the Fito and the Foti variants in one filter tube. The square holes, which are produced by combining lengthwise and crosswise slots, offer special advantages when separating fibres or flaky solids. These filter tubes are mainly targeted at manufacturers of foodstuffs, paints and lacquers.

What slot widths do the high-precision filter tubes come with?

Tunger: What my colleague has already said with regard to slotted screen panels applies here too: all slot widths or hole sizes from 6 µm upwards are technically feasible. We normally offer filter tubes with widths of 10 µm or larger.

Hall 4, Booth 426

www.cpp-net.com search: cpp0116steinhaus

The Optima series is extremely versatile. It includes slotted screen panels, high-precision filter tubes and screen modules.

Lukas Lehmann

Lukas Lehmann

Assist. Editor-in-Chief

Based in the Ruhr Valley

Facts & Figures

Facts & Figures

Based in the Ruhr Valley

Steinhaus GmbH was founded at Mülheim in the Ruhr Valley in 1922. Today, it is part of an international group incorporating over 50 companies and employing more than 3000 people. Siebtechnik GmbH is one of those companies. In addition to Optima slotted screens and high precision filter tubes, Steinhaus manufactures wire mesh conveyor belts, plastic screens and textile and metal filter elements. These are used mainly in the chemical and foodstuffs industries as well as in the pit and quarry sector.

This medium-sized family firm provides work for 160 staff at its Mülheim and Bergisch Gladbach locations and generates a turnover of about 19 million euros. Its products are marketed through its own local branches as well as trade representatives all over the world.

Share: