Reduced life-cycle costs, improved efficiency and increased reliability are the most important features of the piston diaphragm pumps in the MS series. They are used wherever abrasive or very viscous media with a high concentration of solid matter are pumped. This can be slurries and suspensions of all kinds or products from the chemical industry. The spectrum of uses extends from hydraulic transport to reactor and autoclave feeding. In the area of industrial and municipal waste water treatment, feeding chamber filter presses is a popular application.

Markus Pandorf, Reiner Arenz

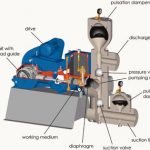

The piston diaphragm pumps in the MS series from Emmerich, designed in a modular system, can be adapted flexibly to suit the needs of the user. To increase running smoothness and efficiency, they are equipped with diaphragm pulsation dampeners on the suction and discharge sides. The pumps in the MS series are an enhanced version of the tried and tested ER pumps. By implementing a series of measures, it was possible to increase the flow rate while maintaining the pump size.

The drive gear is a combination of belt and crank drives, which are located in a cast gear unit housing. This design has already proved very successful in other model ranges. The improvement of the primary sealing on the piston rod has reduced wear and leakage.

The use of diaphragm pulsation dampeners in suction and discharge lines instead of suction and pressure air vessels avoids air intake through the feed flow. This way, the purity of the pumping medium is guaranteed and the flow rate is increased as a result of the higher stroke rate. Due to the efficiency of the manufacturing methods, the production costs for diaphragm pulsation dampeners are no higher than for the traditional air vessel type.

The modular pump head has been optimised as regards compactness and accessibility. Polypropylene (PPH) is used as the standard material. In special cases, PVDF or stainless steel (e.g. 1.4571) can be employed as alternatives. The simple design and low weight of the plastic parts mean that maintenance can be carried out by one person without difficulty.

All MS pumps are delivered with completely redesigned mechanics for automatic regulation of the hydraulic or feed fluid. This ensures a longer service life for the main diaphragm. The extended maintenance intervals also significantly enhance the economic value. Additional regulation by means of frequency converters is pos-sible if desired.

Numerous variants available

58 stages of volumetric displacement can be derived from the 13 basic models. The flow rates vary between 0.5 and 150 m³. The feed pressure is 16 bar, 25 bar or 100 bar respectively for pump heads made of PPH, PVDF and stainless steel. Higher feed pressures are possible as special designs at the customer’s request.

The pumps are suitable for gentle pumping of media with a varying viscosity and consistency as well as for chemically and mechanically aggressive media with a solids content of up to 80%. They are approved for use in potentially explosive atmosphere according to Atex Zones 1 and 2.

cpp 480

Markplatz für Abwasser- und Abfalltechnik

Achema 2006

Marktplatz für Pumpentechnik

Kolbenmembranpumpen der Baureihe MS-PPH

Share: