In the field of processing technologies, pumping delicate, abrasive or coagulating materials represents a special challenge for the pumps. Hose pumps offer essential advantages for pumping this kind of fluid, such as pigment or crystal suspensions or latex. They include the non-shearing and thus non-destructive conveying process, minimal wear, quick and easy cleaning and considerably reduced operating and maintenance costs in comparison with other pumping methods.

Till Völker

The selection of the most suitable pumps for the required process and the material to be pumped is extremely important for ensuring that the process runs smoothly. Not only must all product-contacting parts be resistant to the pumped material, but often numerous additional requirements must be met, for example:

- Gentle conveying of pigments, crystals or other solids containing fluids

- No coagulation of the pumped material during the pumping process

- Suitability for high conveying pressures up to 15 bar

- Minimal resistance to flow in the pump interior

- Protection against dry running and leaks

- Short installation times, flexible connection options and easy start-up

- Short cleaning times and quick change-over to other products or to comply with strict hygiene requirements

- If possible, avoidance of the need to keep spare pumps in stock, as well as low operating and maintenance costs

Hose pumps meet all these requirements. They do not destroy particles in the pumped material, as can sometimes happen if a pump system with a high rotating speed is used. Furthermore, they offer maximum flexibility and the shortest possible downtimes for a great variety of processes.

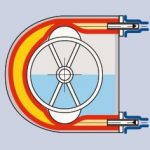

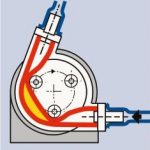

Priming by displacement

Hose pumps are self-priming, rotating, positive-displacement pumps without valves. Conveying takes place through an elastic hose that is resistant to the pumped material. This hose runs close to the inner wall of the pump housing. A rotor with two rollers offset at 180° or three rollers offset at 120° is installed in the centre of the housing. The material is primed and displaced via flexible tubing connected on the priming and discharge side. During the priming process, the displacement rollers compress the hose inside the housing then squeeze the air in the hose into the pressure tubing. Downstream of the rollers, the hose returns to its original shape, thus creating a vac-uum and causing the primed material to be conveyed. When the priming process is complete, the material is transported volumetrically through the hose by the displacement rollers from the suction to the discharge side. Owing to their excellent priming power, hose pumps are suitable for geodetic suction heights of up to 8 m WC.

Two types of pump are available, depending on the application. The low-pressure pumps for conveying pressures up to 4 bar operate as dry-running pumps, i.e. without a liquid lubrication bath in the pump housing. The high-pressure pumps for up to 15 bar conveying pressure are so-called wet-runners, i.e. the hose lies in a liquid lubrication bath.

Gentle pumping of abrasive or delicate materials

The operating principle of hose pumps ensures shear-free conveying, i.e. solids like coloured pigments or crystals are not destroyed by the pumping action. As these solids may also be extremely abrasive, however, hose pumps offer further advantages for these applications, such as robust, wear-resistant hose qualities and a seal-less and valve-less design. This gives them a considerable edge over eccentric screw pumps, which are often subject to severe wear on the rotor/stator assemblies, the rotating mechanical seals and the stuffing boxes.

Due to their shear-free principle, hose pumps are also much more suitable than other designs for pumping materials like latex, which tends to coagulate when pumped. Furthermore, they have virtually no dead spaces. Pigment or latex residues are consequently unable to settle in corners that are awkward to clean – a familiar drawback of pneumatic diaphragm pumps. This is crucially important for many users in the pigments and pharmaceutical industries, where fast and thorough cleaning is essential in order to facilitate quick pigment or batch changes while conforming to very high cleanliness standards. In addition, a hose pump is a closed system, in other words the pumped material is only in contact with the pump hose.

If it fits through the hose, it can be pumped

Ponndorf hose pumps are available in ten different designs – including low-pulsating, double-pump systems – and provide individual solutions for a variety of pumping tasks. Their pumping capacity adapts easily to the requirements of each process. They are suitable for pumping anything that will fit through the hose. The list extends from A for acids through caustic solutions, glues, pharmaceuticals, pigments, sewage, toothpaste and treacle to Z for zinc sulphate. The high availability of these hose pumps ensures reliable production and low operating costs. It is not necessary to keep spare pumps in stock as is usually the case with other pump systems, because there is only one wearing part – the pump hose – which can be replaced easily within minutes.

cpp 401

Share: