Wherever the pharmaceutical and biotech industries work with infectious or genetically manipulated material, the waste water must be sterilized and meet hygienic standards before being released back into the environment. Thermal treatment under pressure using steam is the surest method to achieve these results.

Gerd Braun, Volker Luh

For health and environmental reasons, waste water produced by the pharmaceutical and biotech industries must be thoroughly sterilized before the water returns to the environment. Sterilization in this context means the elimination of all living microorganisms as well as the deactivation of viruses, plasmids, biological agents and DNA fragments in the waste water. This deactivation results in the complete disruption of the biological activities of microorganisms and biological agents (CEN 12740).

Besides incineration, thermal deactivation with steam is the most effective and reliable method of sterilizing waste water. Other processes should only be used when steam sterilization cannot be applied.

The steam temperature and duration of the application are deciding factors for the success of the deactivation. The standard process heats the waste water to 121 °C (2 bar). In these conditions even the most heat-resistant Bacillus stearothermophilus spores are killed off within 15 to 20 minutes and free DNA is also eliminated. In special cases the sterilization is carried out at 134 °C (3 bar) and can take up to 120 minutes.

Plants for thermal sterilization are complex and are custom-made to suit the conditions of each application.

Example: vaccine producer

The vaccine producer Dessau-Tornau GmbH concentrates on the research and development of animal vaccines but also works on clinical samples of human vaccines, for instance against AIDS, malaria and small pox, among others. It is an European leader as a producer of rabies vaccines and continues a more than 80-year tradition of microbiological research and production in Dessau, Germany. It has a total of 560 employees in three locations.

The biotechnological competence of the company is revealed in the responsibility it takes for the safe deactivation and disposal of waste water, for which it employs a thermal sterilization with batch processes. The plant was built by DTS Water and Waste Water Engineering and treats 5 m³/day. It has been in smooth operation for three years.

The plant collects and sterilizes infectious water in the new research and development buildings.

The operating costs of the batch sterilization are slightly higher than those of a continuous process, but much less time and effort are necessary for process monitoring, since it is the safest and most reliable deactivation method. The operating costs result mostly from steam production, but recy-cling the heat energy increases efficiency.

Fully automatic or manual

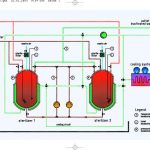

The effluent gravitates into the 1 m³ tank, which is completely insulated and can be heated so that it too can be sterilized. The sterilizing filter in the ventilation ensures that no spores reach the external environment. The sterilization plant can operate manually or fully automatically. As soon as the water in the tank reaches a preprogrammed volume, the first of the two sterilizers automatically fills with a 500 liter batch of waste water. Two sterilizers are combined to meet the high capacity of the plant.

The sterilizers are insulated pressure tanks with a durable double shell and 0.75 m³ capacity. They are fitted with the necessary automatically powered controls. The entire plant is constructed of stainless steel 1.4571 and the exhaust is fed through a sterilizing filter.

As soon as the necessary volume is reached, the sterilization process itself begins automatically. The operations, duration, volume and temperature are carefully monitored, controlled and recorded.

The first sterilizer is heated directly with steam from the factory network to the sterilization temperature of 121 °C and held constant for 20 minutes. Afterwards the dual plant uses the heat of the active sterilizer and passes it on to the next sterilizer programmed to operate, hence saving energy and coolant water.

During the entire deactivation process, a special hot water pump station circulates the contents of the sterilizer to ensure a homogeneous temperature and avoid stagnant zones in the piping. After sterilization the waste water is cooled to 35 °C by pumping coolant water between the double shell and then fed into the canal.

The example of Dessau-Tornau highlights the reliability and efficiency of the thermal sterilization of water in the pharmaceutical and biotech industries. Thermal sterilization plants for infectious waste water can also be suited to task and client needs for continuous operations.

cpp 458

Impfstoffwerk Dessau-Tornau

Homepage of Enviro-Chemie

Share: