Using advanced digital automation architecture and a unique approach to project management, Shanghai Secco beat the schedule for start-up of one of China’s largest petrochemical complexes. The 10-plant integrated facility was constructed in record time – from bare ground to a fully functional, world-class ethylene cracker complex in just 27 months, three months ahead of schedule. The plant’s success was due in no small part to the decision to use a main instrument vendor to manage the project, and the choice of PlantWeb digital automation architecture with Foundation Fieldbus to speed construction, deliver ongoing operations and maintenance benefits, and establish an open leading edge platform for future growth.

Adrian Howell, Stanley Ee

When Secco, a joint venture between BP, Sinopec and Shanghai Petrochemical Corporation (SPC), decided to build a new petrochemical facility, the company had three goals:

- The complex needed to be a world-class facility that would reduce China’s increasing dependence on petrochemical imports.

- The facility needed to give autonomy and control over production efficiency from the feedstock through to the downstream petrochemical derivatives.

- The plant required cutting-edge automation that would give the company a competitive advantage well into the future.

In addition, the complex needed to be built inside an incredibly aggressive schedule, targeting to be operational on a deadline that was only two and a half years after the initial groundbreaking.

Sizing up the project

The US$ 2.7 billion ethylene cracker complex is located in Shanghai Chemical Industrial Park in China’s Shanghai Province, about 50 kilometres (31 miles) south-west of Shanghai. Building the plant required tremendous cooperation between Secco, the municipality of Shanghai and the Chinese government. The Secco plant reduces dependence on imports and competes effectively with any plant in the world.

The facility comprises ten separate plants – plans allow the addition of two more plants if necessary – with a main ethylene cracker capable of generating 900,000 metric tons of feedstock per year. Other plants rely on this feedstock to produce polyethylene (600,000 MTY), polypropylene (250,000 MTY), styrene (500,000 MTY), polystyrene (300,000 MTY), acrylonitrile (260,000 MTY), aromatics (200,000 MTY) and butadiene (90,000 MTY), as well as the required utility facilities. Another plant in the complex is owned by Lucite, but under contract to be operated by Secco.

Each of the 10 Secco plants is one of the largest of its kind in the world, enabling the facility to produce about 2.3 million metric tons of chemical products annually.

The project goals and challenges drove the selection of two strategies rarely employed with a facility of this size:

- Rather than hiring a general contractor to oversee the project, Secco elected to use an integrated project management team approach, under which each key plant in the complex had a lead project contractor. Secco selected Emerson Process Management as the main instrument vendor (MIV) to not only engineer and implement the automation and control systems, but also to help manage multiple international and local suppliers for each of the 10 plants in the facility.

- Secco additionally decided to leverage the technologies available in digital, intelligent field devices, selecting Foundation Fieldbus communications as a central feature of the facility’s automation approach. Foundation Fieldbus not only greatly simplified the construction and commissioning phase, plant officials also expect it to reduce maintenance costs by as much as a third.

Targeting a challenging completion date

An aggressive schedule posed the biggest challenge – to go from bare ground to a fully functional, world-class facility in two and a half years. As construction plans came into being, a main goal – set in 2001 – was to have the plant operational by July 2005. At the time, the target date seemed impossible. Meeting target required bringing an enormous ethylene cracker online, making sure that all the downstream units were operational and available, and accomplishing all this with technology that was unfamiliar to many of the people involved.

To ensure a smooth launch, the downstream plants were started prior to the ethylene cracker, relying on imported feedstock to ensure everything was in working order. The plants did very well; in particular, the polypropylene unit came online very smoothly.

The utility boiler start-up occurred on August 23, 2004, and mechanical completion of all ten plants was on December 28, 2004. The downstream plants were online in February 2005 and the ethylene start-up was on March 18, 2005, more than four months ahead of the original schedule. The ethylene cracker was running on-spec in just 10 hours and 45 minutes.

Organising for success with MIV approach

Secco decided that the MIV approach would be best for the project. A main instrument vendor would be selected, who would then work with Secco to implement the automation and control systems, and also help to manage the multiple international and local Engineer-Procure-Construct (EPC) suppliers for each of the ten plants.

After evaluating several different suppliers, Emerson Process Management was chosen, both for their breadth of digital automation, including quality field instrumentation and systems, and for their experience in managing projects of this scale. Emerson and Secco created framework agreements for all EPC contractors to use, enabling consistency across the site for current and future operations. This was key to Secco’s long-term goals of ease-of-use and reduced maintenance, making sure that every process in each of the ten plants was developed consistently. As MIV, Emerson developed the functional design specification, and communicated and enforced conformance and standardisation by every vendor as applicable throughout the facility, a vital step in maintaining operating efficiency in the tightly integrated complex.

Emerson actually provided separate teams for each of the ten plants, rather than having a single team moving from one plant to the next, and also appointed a program director and an engineering and quality manager to oversee all 10 plants. This MIV organisation was crucial to the goal of a fast start-up.

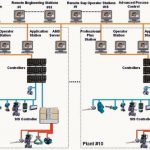

The MIV approach was equally critical to the success of the Secco strategy of using a single control room for all ten plants. In order to economically connect all the various systems, including 14 outstations, to a single control room, all the systems needed to be consistent. Emerson’s MIV leadership helped achieve the uniformity, while digital automation architecture with Foundation Fieldbus communications provided the needed technology.

Applying the digital automation

Emerson’s PlantWeb digital architecture is used throughout the complex which is the largest Foundation Fieldbus installation in the world. Over 13,000 of the plants’ 20,000 devices are networked with fieldbus technology to deliver digital process, control and device diagnostics information.

Overall, the facility comprises over 48,000 loops with about 166,000 I/O tags. Around 25,000 points are hardwired to the automation system. There are over 70,000 cables in the facility. The digital architecture integrates ten DeltaV systems with a single global historian and remote operations functions. All ten automation systems are managed from a single remote control room.

Foundation Fieldbus was the technology choice from the start

The Foundation Fieldbus devices and systems gave several advantages, including openness and intelligent asset management. While the most appropriate instrumentation was selected for each process, not all the devices were available from Emerson. The ability to integrate other supplier devices genuinely brought out the flexibility of PlantWeb with Foundation Fieldbus, since this automation is designed around an open, standards-based platform on which industry-wide devices can participate.

While Secco knew that a fieldbus approach would save considerable amounts of cabling, a conservative approach was taken to the number of devices connected on each segment. Designs were limited to no more than 12 devices, and the average ended up as five devices per segment, where each segment varies between two and 11 devices. Foundation Fieldbus enabled the performance of basic PID control in the intelligent field devices. The choice was made to locate the PID algorithms at the point of final control – in the valve controllers. This control-in-the-field (CIF) helps give the improved reliability of a truly distributed control system. CIF also significantly reduces communication between the automation system and the field devices, adding to increased reliability. Only single-loop control was implemented in the valves – all complicated control, such as cascade and multi-element strategies, is done in the DeltaV digital automation system. Control function blocks could be performed in any of the field devices or in the automation system, since it is an easy drag-and-drop software choice.

Asset management aids commissioning and future operations

The intelligent field devices also deliver process and equipment health information to the AMS Suite within PlantWeb. While Secco is still discovering the benefits of the asset management system, it has already provided great value in key areas, such as allowing the use of the AMS Suite: Intelligent Device Manager that enables verifying the range inside the transmitter, while sitting in the comfort of the control room. The AMS ValveLink application is being used to obtain valve signatures, so that Secco can monitor valve states and take action to optimise performance, avoiding abnormal situations.

The asset management suite will greatly improve the lifespan of the complex’s assets by enabling “predicting” and taking action to prevent any problems before they actually occur. For example, it is possi-ble to look at all the information coming from the intelligent valves and understand the changes in the friction coefficients, in order to know if there is a potential for leakage or early breakdown.

cpp 427

Shanghai Chemical Industry Park

Shanghai Chemical Industry Park (SCIP), a professional petrochemical-dominated development zone, is located on the north coast of Hangzhou Bay, 50 km from the centre of Shanghai. The total planning development area of the Park is 29.4 km2. It will extend to the west and combine with the existing SPC site to form a 60 km2 chemical production belt. RMB 150 billion will be invested during phase 1, and the key investment areas are the petrochemical and natural gas chemical industry, synthetic new material and fine chemical industry downstream projects.

Shanghai Chemical Industry Park is built with the advanced integrated development concept of a world-class chemical industrial park. It will provide investors in the Park with the best possible services through the concentration of chemical projects, utilities and infrastructure, logistics transportation, environmental protection and administrative services. At present, projects with a capital investment of more than US$ 8 billion have settled in the Park. Multinational corporations, such as BP, BASF, Bayer, Huntsman and domestic large-scaled companies led by Sinopec, SPC GPCC and HYG, have been the Park’s major investors. In the near future it will be one of the largest chemical production bases in Asia and the most concentrated world-scale chemical park.

Shanghai SECCO Petrochemical Co., Ltd

Shanghai Chemical Industry Park

Fieldbus Foundation

Share: